Maintenance Informatio

FOR YOUR

OW

N SAFETY. TURN

AWARNING

SWITC

H "OF

F'

.

AND

RE

MOVE PLUG

FROM

POWER SOURCE BEFORE LUBRICATING OR

DOING

ANY

MAINTE

NANCE

ON

YO

UR SA

W.

GENERAL

An occasional

coa

of

paste

wa

on the work table will

allow the

wo

od being

CUt

0 glide smoothly across the

work

surface.

ARM

BE

ARINGS

Lubricate the arm

Dear

gs I a er

10

hou

rs

of

use.

Re-

oil a

fter

eve

50

ours of use enever the

re

is a sque

ak

corning ro the bearings

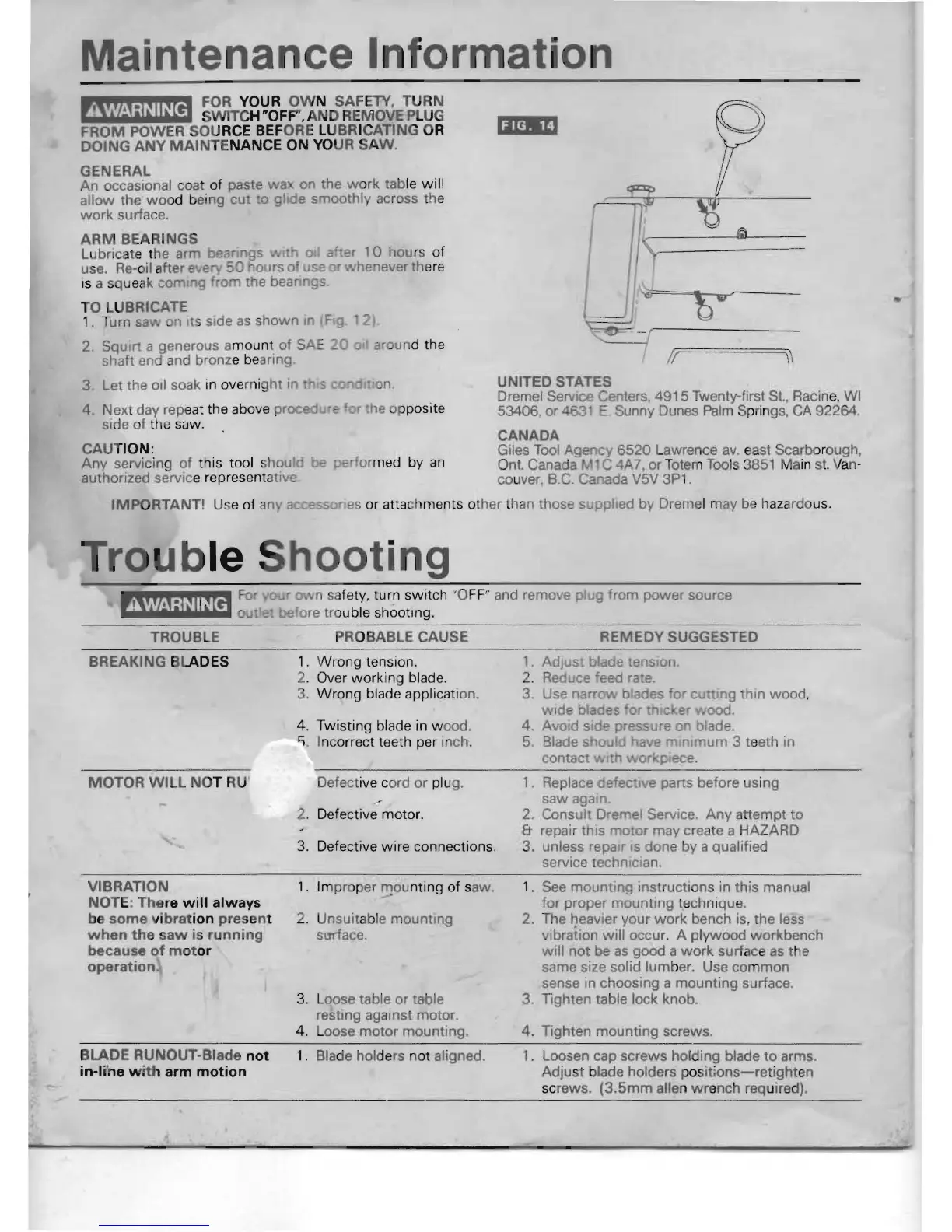

TO LUBRICATE

1.

Turn

sa

n Its side

as

shown

In

F 2).

2 SquIrt a generous amount

of

S around the

shaft end and bronze

be

aring.

3

let

the oil soak in over ight

In

4. Next day repeat the above proced

sIde of the saw.

CAUTION:

Any

servicing of this tool shaul

armed by

an

authOrized service representativ

••

(.C]

If

\\

UNITED STATES

Dremel SeNlee Centers, 491 5

Tw

enty-first St.. Racine,

WI

53406, or 463

E.

Sunny Dunes

Palm

Springs.

CA

92264.

CANADA

Giles

Tool

Agency

6520

Lawrence

avo

east Scarborough,

Ont. Canada C 4A 7,

or

Totem Tools 3

851

Ma

in

st.

Van-

couver B.C. Canada V5V 3P1 .

IM

PO

RTANT! Use

of

an a

es

or attach ments other than those

Su

piled by Dremel may

be

h

az

ardous.

rom power source

TROUBLE

PROBABLE CAUSE

AEMEDY

SUGGESTED

AWARNING

ooting

BREAKING

BLA

DES

MOTOR

WILL

NOT RU

1.

Wrong tension .

2. Over working blade.

3.

Wrong

blade application.

4. Twisting blade in wood.

~

.

Incorrect teeth per inch.

Defective cord or

pl

ug.

2. Defective motor.

3. Defective wire connections.

sawagam

2.

Consul' Dremel Service. Any a

tempt

to

& repair

thiS

'TIotor may create a HAZARD

3. unless repa r

IS

done by a qualified

service technICI

an

VIBRATION

NOT

E:

The

re

will

always

be

some

vi

bra

t

ion

pres

ent

when

the

saw

is

running

because

of

m

ot

or

operation

.

1.

Im

pr

per

lTlou

nting

of

saw.

2. Unsuitable mounting

smface.

3.

Loose table or table

resting

aga

i

nst

motor.

4. Loose motor mounting.

1.

See

mounting instructions in

this

manual

for proper mountIng techni

qu

e.

2. The

~eavler

your

work

bench is, the less

vibratIon

will

occur. A plywood workbench

will

not

be

as

good a

work

surface

as

the

same size solid

lum

ber. Use common

sense in choosing a mounting surface.

3.

Tighten table lock knob.

4.

Tighten mounting screws.

BLAD

E RUNOUT-Blade

not

1.

Bla

de holders not aligned.

1. Loosen cap screws holding blade

to

arms.

in-l

i'ne w

ith

arm

motion

Adjust blade holders

poS

Itions-re

t

ight

en

screws.

(3.5mm

allen

wr

ench required).

Loading...

Loading...