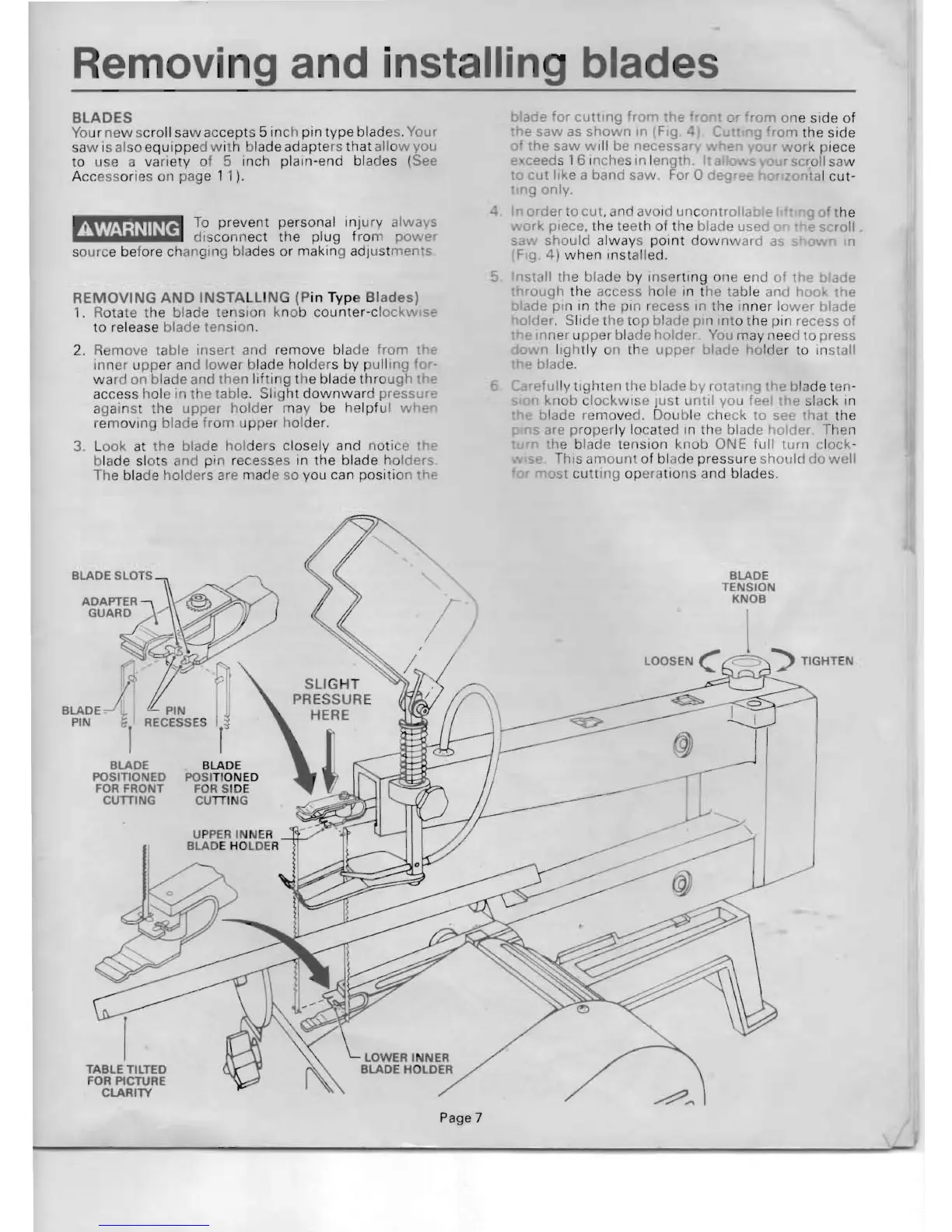

BLADE

POSITIONED

FOR

FRONT

CUmNG

TABLE TILTED

FOR PICTURE

CLARITY

BLADE

POSITIONED

F

OR

SIDE

CU

TII

NG

UP

PE

R INNER

BLADE HOLDER

Removi 9 and installin

blades

Page 7

BLADES

Yo

u r new scroll

sa

w

ac

cept

s 5 inch pin

type

blades. Your

saw i al o

equippe

dw

it h

ladeadapt

ers

that

allo

wyou

to use a var

iety

of 5 inch

plain·end

blades (See

Acc

ess

or

ies 011 page 1 1

).

To

prevent

personal injury

alwa

s

AWARNING

di

can ect

the

plug

fro

powe

source before changing bl des or making adjust

ments

REMOVING

AND

INSTAL

LI

NG (P

in

Type

Bl

ades)

1.

A

ot

te the blade Ie si n knob c

ounter-c

l

ockw

s':?

to

release blade

tens

ion.

2. A move table

insert

and re

mov

e bl a

de

from t

inner u

pp

er and low er blade hol

der

s by u

il

ing

or-

wa

rd on b

la

de

and

the

n li

fting

t e blade

thr

o

ugh

t .

ac

cess hal in t e tabl

e.

Sli

ht

downwar

d

pressur

ag

ainst the

upper

hold

er m y

be

h

Ipf

ul

whe

remo

ving blade

fr

m pper holde

r.

3. L

ook

at

th

e blade

hol

der closely and notice t

bla

de

sl

ot and pin recesses in the blade h

old

ers

Th

e blade

ho

l

der

s are made so you can

positi

on tn!?

lade

or

cut

Ing

rrom

hE-

0

he

saw

as

shown

In

(Fig

o

the

saw

w i

ll

be necessar

_ ceeds

16 inches in l

ength

.

I'

s

o

cut

like a ba nd saw. For 0 deg"o't! 0 -

n nly.

der

to

cut.

an avoid unconlTO I

(t

he

piece, the teeth

of

the blade USE" roll .

should

a

lw

ays

point

down

w ard

as

..

nm.,,"'n

4;

when

Installed.

5

Insta

ll the blade

by

Inse

rting

one end 0

the

I e

rough

th access h

Ie

in the table and

hoo

ne

bade

pin

In

the pin leces in the i

nner

lo

wer

blade

older

. Slide the t

op

blade

pm

Int

o the pin recess

of

Inner uppel blade

hold

r.

Y u may need 0 press

o n li

gh

tly n the

upp

er

blade

ho

lder to Instal!

ad

e.

Ca

e u

lly

t

igh

t n the lade

by

rot t

he

ll

iade t n-

on

knob

c

lockwi

e

lus

t

unt

il

yo

u feel P slack

in

blade re moved. Doubl eh ck

to

se hat the

re

pr

o rly 10 ated in the blade

holder

Th n

r he blade tension

knob

ON

E fu ll turn cl

ock

-

_

'"

ThiS

amo

un of blad pressure ShOlll:!

(,jo

w

I!

~st

cutt

ing op

er

tion and blades.

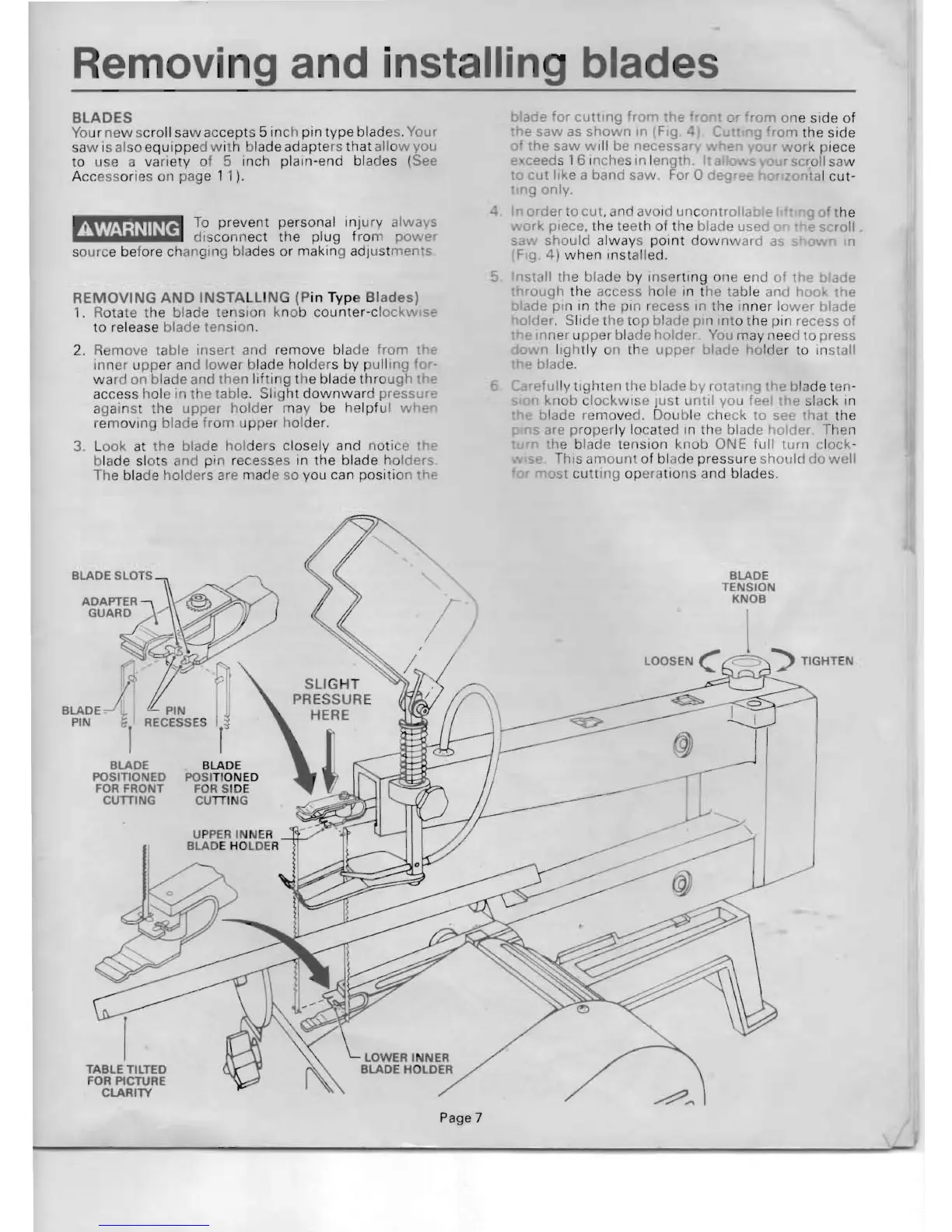

BLADE

TENSION

KNOB

Loading...

Loading...