18

Scroll Saw/Moto-Saw Tips

• Three things will have great effect on the

cut when using a scroll type saw:

1. The material being cut.

2. Blade speed (strokes per minute blade).

3. Cutting speed (how fast material is

pushed into blade).

• There is not ONE blade that is the best for

every given job.

• A coarse blade should be used for thicker

material and a finer blade for thinner

material. The thinner the blade, the

sharper the turn it can execute.

• There should always be 3 to 4 teeth in

contact with the work at all times.

• Cutting hard material like metal and

material that can melt, like acrylic, will

generally require slower speed on the tool

and a lower feed rate.

• The best starting point on any cut is at a

point or corner because you can control

the intersection of the cut and make it as

smooth as it needs to be.

• Certain actions will require practice – like

cutting a corner or a 180° turn.

• Saws that scroll can present a challenge

when attempting a straight cut. With some

practice, it’s easy to do. Practice

compensating for the grain by turning the

material slightly to stay on a straight line.

Once the degree of compensation is

determined for any material, being able to

then cut a straight line will only be a matter

of blade selection, speed, and feed rate.

• If a blade seems to be cutting slowly or

seems to wander with little means of

control, chances are the blade is becoming

dull. There’s no substitute for a sharp

blade. Wood and metal will both dull a

blade quickly. If a lot of cutting is being

completed, change your blade as often as

necessary.

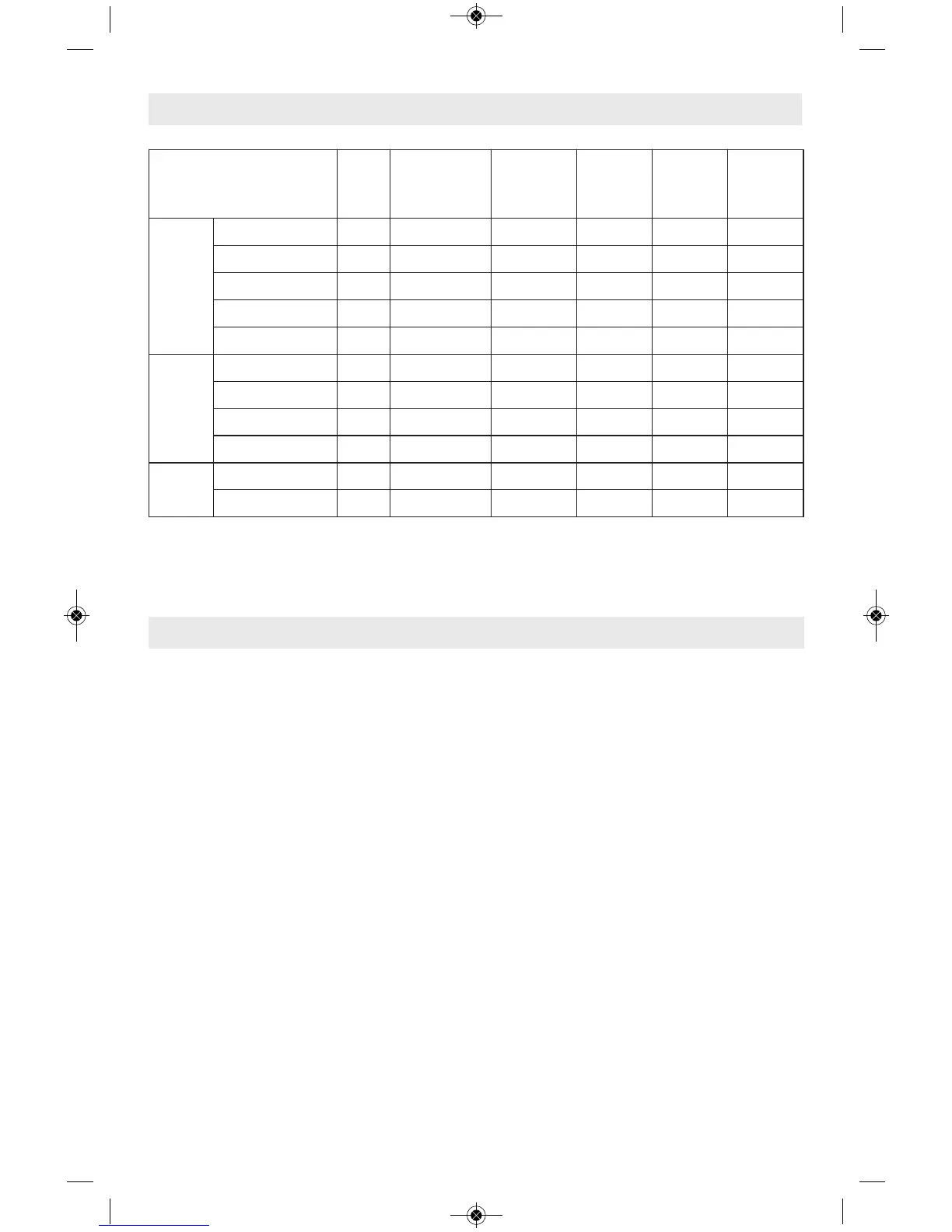

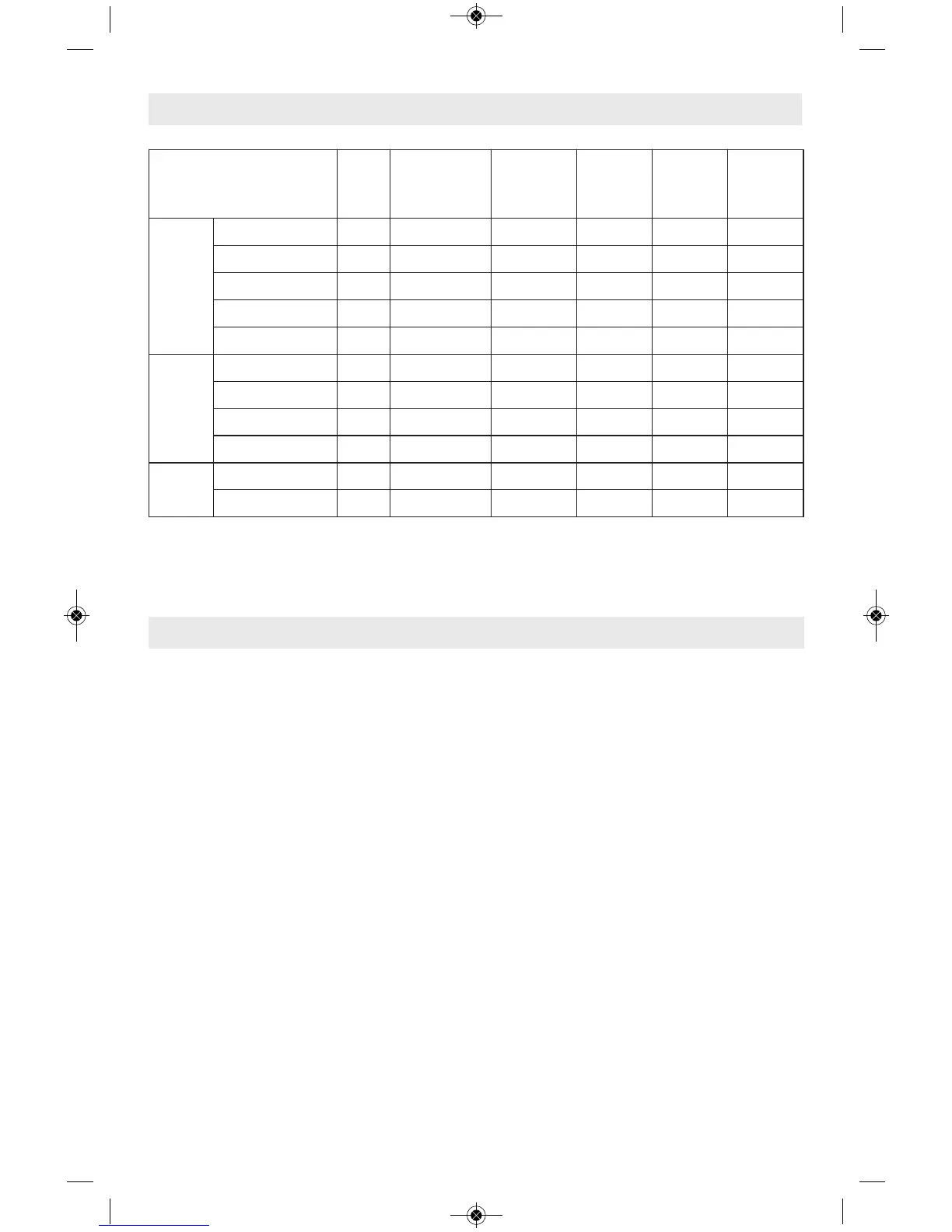

Material

Tool

Speed

Recommended

Thickness

MS51 Wood

& Plastic

Blade

MS52 Fine

Wood

Blade

MS53

Metal

Blade

MS50 Side

Cutting

Blade

Wood

Plywood 6 .75” x x x

Pine 6 .75” x x x

Poplar 6 .75” x x x

Balsa 6 1.75” x x x

Laminate Flooring 6 .5” x x x

Metal

HVAC 6 20-ga. x

TIN 6 20-ga. x

AL sheet 6 20-ga. x

Gal. Sheet Metal 6 20-ga. x

Plastic

Plexiglass 4 .2” x x x

PVC Pipe 4 .75” x x x

Speed Settings

Loading...

Loading...