1. In seriesflow applications, the coil is mounted after the

furnace in an enclosure in the supply air stream. The furnace

blower is used for both heating and cooling airflow.

2. In parallel flow installation, dampers must be provided to

direct air over the furnace heat exchanger when heat is desired

and over the cooling when cooling is desired.

IMPORTANT: The dampers should be adequate to prevent

cooled air from entering the furnace, and if

manually operated, must be equipped with

means to prevent operation of either the cooling

unit or furnace unless the damper is in the full

cool or full heat position.

WARNING

The coil MUST be installed on the air discharge

side of the furnace. Under no circumstances should

the air flow be such that cooled, conditioned air can

pass over the furnace heat exchanger. This will

cause condensation in the heat exchanger and

possible failure ,of the heat exchanger that could

lead to a fire hazard and/or hazardous conditions

that may lead to bodily harm. Heat exchanger

failure due to improper installation may not be

covered by warranty.

Gas piping shall be of such size and so installed as to provide

a supply of gas sufficient to meet maximum demands without

undue loss of pressure between the gas meter and the furnace. It is

recommended that the gas line to the furnace shall be a separate

line direct from the meter, unless the existing gas line is of ample

capacity. Refer to gas pipe capacity table in the National Fuel Gas

Code (ANSI 7-,223.1)or the CANI-B 149 Installation Code.

Use ajoint compound (pipe dope) that is resistant to the action

of liquefied petroleum gases or any other chemical constituents of

the gases to be conducted through the piping.

NOTE: In order to make proper input adjustments, minimum and

maximum gas supply pressure limits shown on the rating

plate must not be exceeded.

Before any system of gas piping is finally put into service, it

should be carefully tested to determine if it is gas tight. Check all

piping for leaks using soapy water and a brush. The piping must

stand a pressure of six (6) inches of mercury for a period of ten

(10) minutes or as required by local authority.

WARNING

The furnace and its individual shutoff valve must

be disconnected from the supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.5kPa or

14"w.c.).

The furnace must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at pressures equal to or

less than 1/2 PSIG (3.5kPa or 14"w.c.). Failure to

follow the above procedures couId lead to a

hazardous condition and bodily harm. o

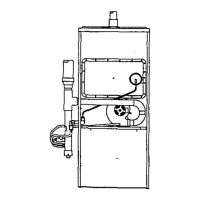

Figure 1.6 GAS CONNECTION METHODS

,_LTS

r• • , • •

FIELD

SHUT OFF

VALVE

l'

I_ DRIP tea

FIELD INSTALLED

GROUND UNION

This furnace is manufactured for use with Natural gas and

must be converted using the proper LP conversion kit for use with

LP (Propane) gas. For LP (Propane) gas, a tank regulator is

required to reduce supply pressure to 12"-13"w.c. For manifold

pressure, see Table 2.13.

A main manual shut off valve must be used in the gas piping.

The shut off type and location must follow local codes and should

always be in an accessible but protected location. In the absence

of local codes the _conm_nded methods for installing the gas

piping to the furnace are shown in Figure 1.6.

The gas valve contains two threaded ports for a 1/8" NPT tap

in order to test incoming gas pressure and outgoing manifold

pressure (See Figure 1.12).

CAUTION

Many soaps used for leak testing are Corrosive to

certain metals. Piping must be rinsed thoroughly

with clean water after leak check has been

completed.

WARNING

Never use an open flame when testing for gas

leaks! Use of an open flame could lead to a fire or

explosion.

20246506 Issue 9939 Page 6 of 22

Loading...

Loading...