FAectrical:

The control system depends on the correct polarity of the

power supply. Connect "hot" wire (H) and "ground" wire "G'"' as

shown in Figures 1.21 & 1.22. Reference table 1.20 for furnace

over current protection, current rating and wire size. Use copper

wire only for ll5V-supply service to unit. When replacing any

original internal wiring, use only 105°C, 16 AWG copper wire.

Instructions for wiring the thermostat are packed in the

thermostat (field supplied) box. Make the thermostat connections

as shown in Figures 1.21 & 1.22 at the 24-volt terminal board

located in the control box.

When installing optional accessories to this appliance, follow

the manufacturer's installation instructions included with the

accessory. Other than wiring for the thermostat, a minimum of

type T (63°F rise) must be used.

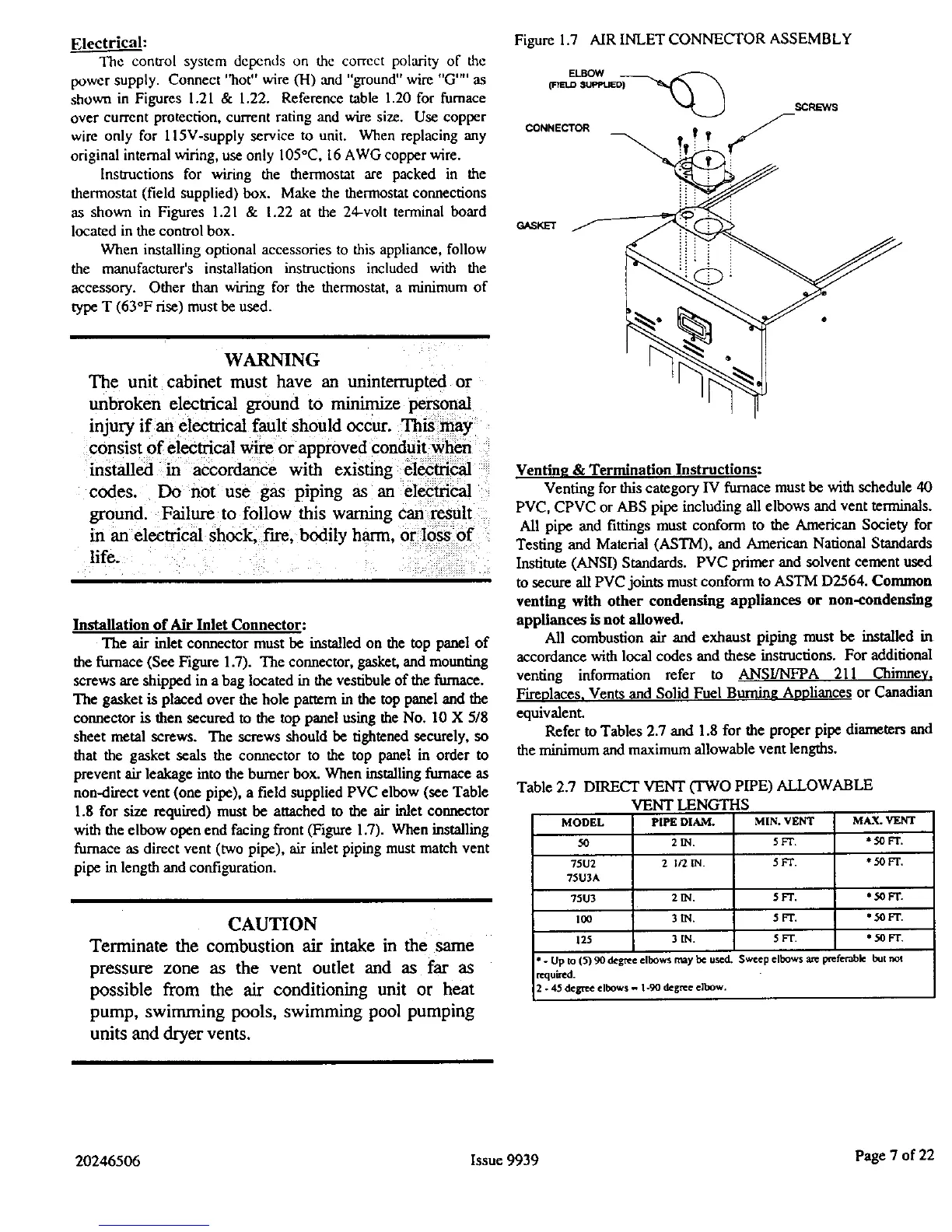

Figure 1.7 AIR INLET CONNECTOR ASSEMBLY

CONNE_OR

GASKET

WARNING

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. This may

consist of electrical wire or approved conduit when

installed in accordance with existing electrical

codes. Do not use gas piping as an electrical

ground. Failure to follow this warning can result

m an electrical shock, fire, bodily harm. or loss of

life.

Installation of Air Inlet Connector:

The air inlet connector must be installed on the top panel of

the furnace (See Figure 1.7). The connector, gasket, and mounting

screws are shipped in a bag located in the vestibule of the furnace.

The gasket is placed over the hole pattern in the top panel and the

connector is then secured to the top panel using the No. 10 X 5/8

sheet metal screws. The screws should be tightened securely, so

that the gasket seals the connector to the top panel in order to

prevent air leakage into the burner box. When installing furnace as

non-direct vent (one pipe), a field supplied PVC elbow (see Table

1.8 for size required) must be attached to the air inlet connector

with the elbow open end facing front (Figure 1.7). When installing

furnace as direct vent (two pipe), air inlet piping must match vent

pipe in length and configuration.

CAUTION

Terminate the combustion air intake in the same

pressure zone as the vent outlet and as far as

possible from the air conditioning unit or heat

pump, swimming pools, swimming pool pumping

units and dryer vents.

Venting & Termination Instructions:

Venting for this category IV furnace must be with schedule 40

PVC, CPVC or ABS pipe including all elbows and vent terminals.

All pipe and fittings must conform to the American Society for

Testing and Material (ASTM), and American National Standards

Institute (ANSI) Standards. PVC primer and solvent cement used

to secure all PVC joints must conform to ASTM D2564. Common

venting with other condensing appliances or non-condensing

appliance* is not allowed.

All combustion air and exhaust piping must be installed in

accordance with local codes and these instructions. For additional

venting information refer to ANSI/NFPA 211 Chimney,

Fireplaces, Vents and Solid Fuel Bumin_ Anoliances or Canadian

equivalenL

Refer to Tables 2.7 and 1.8 for the proper pipe diameters and

the minimum and maximum allowable vent lengths.

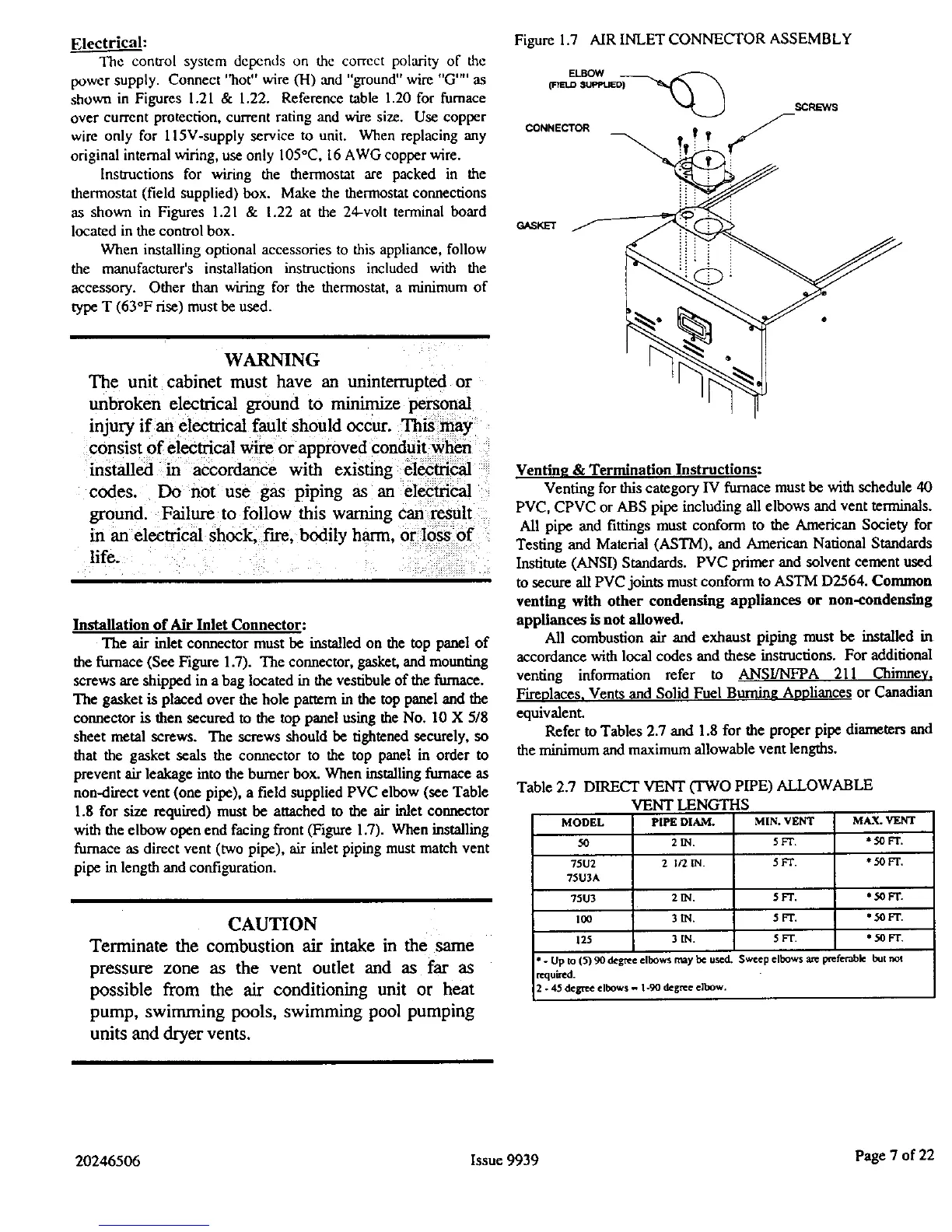

Table 2.7 DIRECT VENT (TWO PIPE) ALLOWABLE

VENT LENGTHS

MODEL PIPEDIAM.

50 2_.

75U2 2 1_.

75U3A

75W 2_.

1_ 3_.

125 3_.

MIN. VENT MAX. VENT

5FT. *:;OFT.

5FT. * 50 FT.

5FT. * 50 FT.

5zr. * 50 F'r.

5FT. *50FT.

*- Up to (5) 90 degree elbows may be used. Sweep elbows are poeretable but not

required.

2 - 45 degree elbows - 1-90 degree elbow.

20246506 Issue 9939 Page 7 of 22

Loading...

Loading...