4 … 6

MAINTENANCE AND TESTING

Annually check the switch for proper operation

Low Gas Pressure Switch:

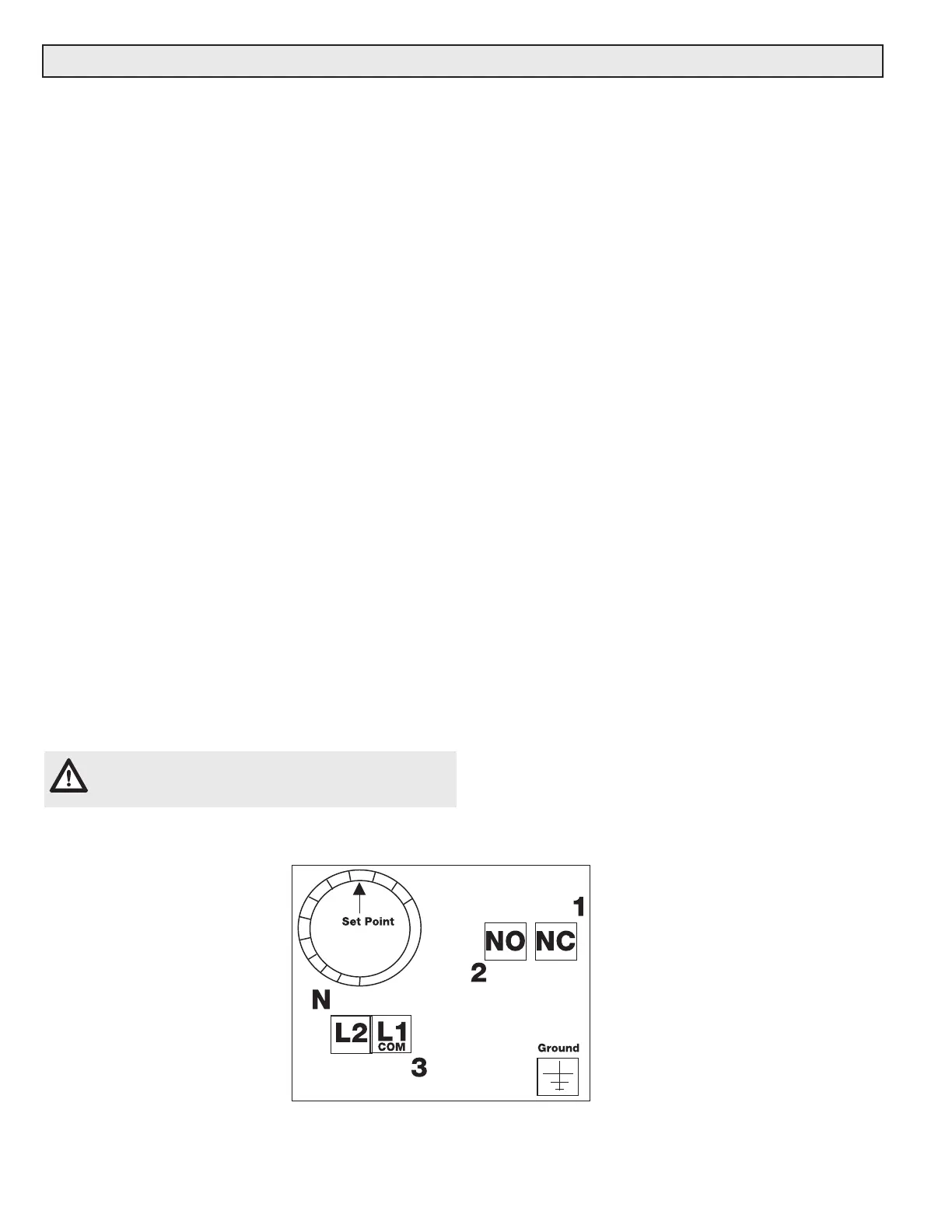

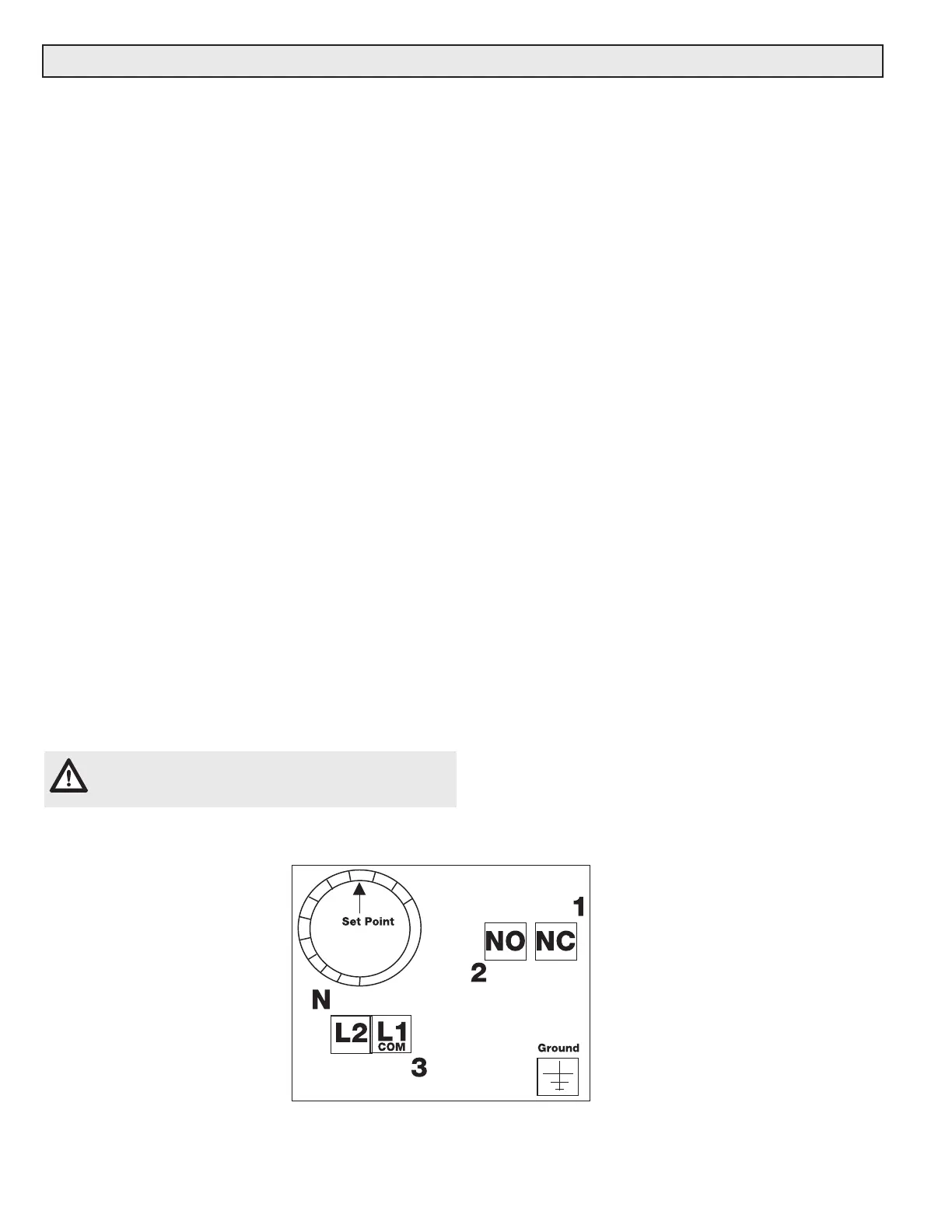

First, connect a meter capable of reading +/- 0 ohms to •

the NO and COM contacts, and verify that the NO and

COM contacts are made. Measure the resistance, and if

the resistance is more than 1 ohm, remove switch from

service. is more than 1 ohm. (See terminal illustration

below for guidance).

Then, verify that the low gas pressure switch will change •

state when a low gas condition is sensed by connect-

ing a meter capable or reading +/- 0 ohms to the NC

and COM contacts and then by causing the switch to

go into a fault condition. Once the fault occurs, Measure

the resistance, and if the resistance is more than 1 ohm,

remove switch from service. is more than 1 ohm.

To cause the fault, perform one of the two procedures:•

Turn the pressure switch setpoint counterclockwise 1.

until the switch trips.

Depressurize the volume of gas the low gas pressure 2.

switch is sensing. For FRI/6 regulators, this can be

done by opening the side tap on the oppositive side

of the FRI/6 regulator. For DMV and MBC safety

shutoff valves, this can be done opening the port

1 pressure tap. For SV valves, open port 1 of the

upstream valve.

Allow the burner to go through a startup sequence, and •

then verify that the burner faults and is not allowed to

light off.

Close all test taps (ports) and open upstream ball valve.•

When finished, close all pressure test points used, and •

then open the upstream ball valve SLOWLY to allow gas

pressure to gradually bleed into the system.

CAUTION: Opening the upstream ball valve too fast

can permanently damage the regulator.

High Gas Pressure Switch:

First, connect a meter capable of reading +/- 0 ohms to •

the NC and COM contacts, and verify that the NC and

Measure the resistance, and if the resistance is more

than 1 ohm, remove switch from service. is more than 1

ohm.

Then, verify that the high gas pressure switch will •

change state when a high gas condition is sensed by

connecting a meter capable or reading +/- 0 ohms to

the NO and COM contacts and then by causing the

switch to go into a fault condition.

To cause the fault, perform one of the two procedures:•

Turn the pressure switch setpoint clockwise until the 1.

switch trips.

Pressurize the volume of gas the high gas pressure 2.

switch is sensing. This can be done by closing the

downstream ball valve, opening port 3 tap on a DMV

and MBC safety shutoff valves, or port 2 or 3 of the

downstream SV valve, and then using a pump to

pressurize the test chamber.

Measure the resistance across the NO and COM •

contacts. If the resistance is more than 1 ohm, remove

switch from service.

Allow the burner to go through a startup sequence, and •

then verify that the burner faults and is not allowed to

light off.

When finished, close all test taps (ports) and open the •

dowmstream ball valve.

NOTE: A resistance of more than 1 ohm indicates

that the switch contacts are starting to either cor-

rode or carbonize.

Terminal Illustration

Do not similate fault conditions while the

burner is firing.

Loading...

Loading...