3 … 4

• Remove the clear cover from the switch.

• Use 14 or 16 AWG wire rated for at least 75°C

• Route the wires through the conduit connector

• Connect the wiring to the appropriate screw terminals.

• Replace the clear cover from the switch.

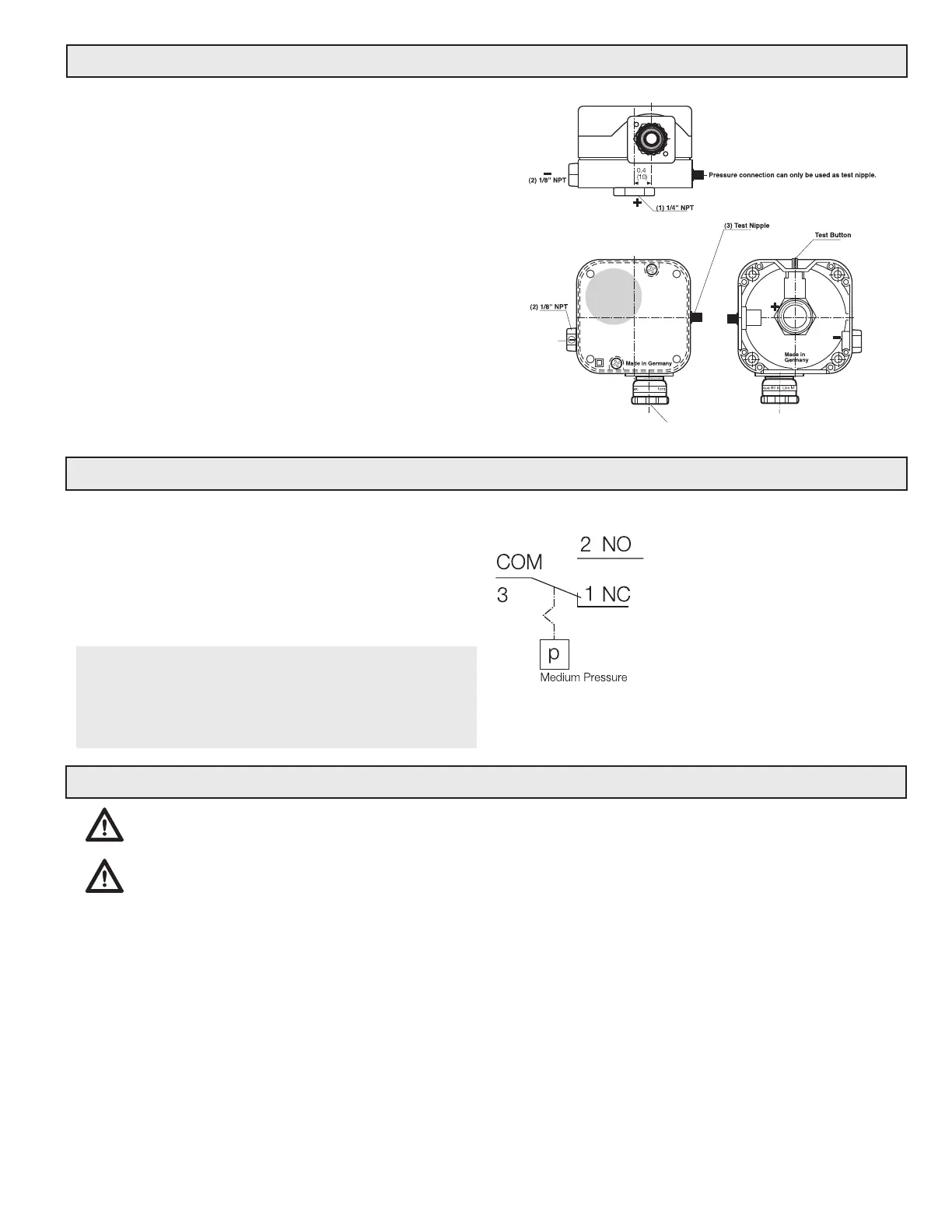

WIRING

CAUTION: All wiring must comply with local electrical

codes, ordinances and regulations.

CAUTION: Do not exceed the switch ratings given in

the specifications and on the switch.

AA...A2 switching function

As pressure rises above

setpoint:

1 NC opens, 2 NO closes

As pressure falls below

setpoint:

1 NC closes, 2 NO opens

Adjusting the Set Point

• Remove the clear cover from the switch.

• Adjust the switch to the desired set point by turn-

ing the

dial. The white arrow on the dial indicates the set

point.

• After adjusting the set point, verifty that the pressure

switch operates as intended by using an accurate pres-

sure gauge connected upstream of the switch.

• Replace the clear cover.

Automatic Reset and Operation

The NC contact of the AA...A2 breaks when pressure rises

above the set point. It makes automatically when pressure

falls below set point.

ADJUSTMENT AND OPERATION

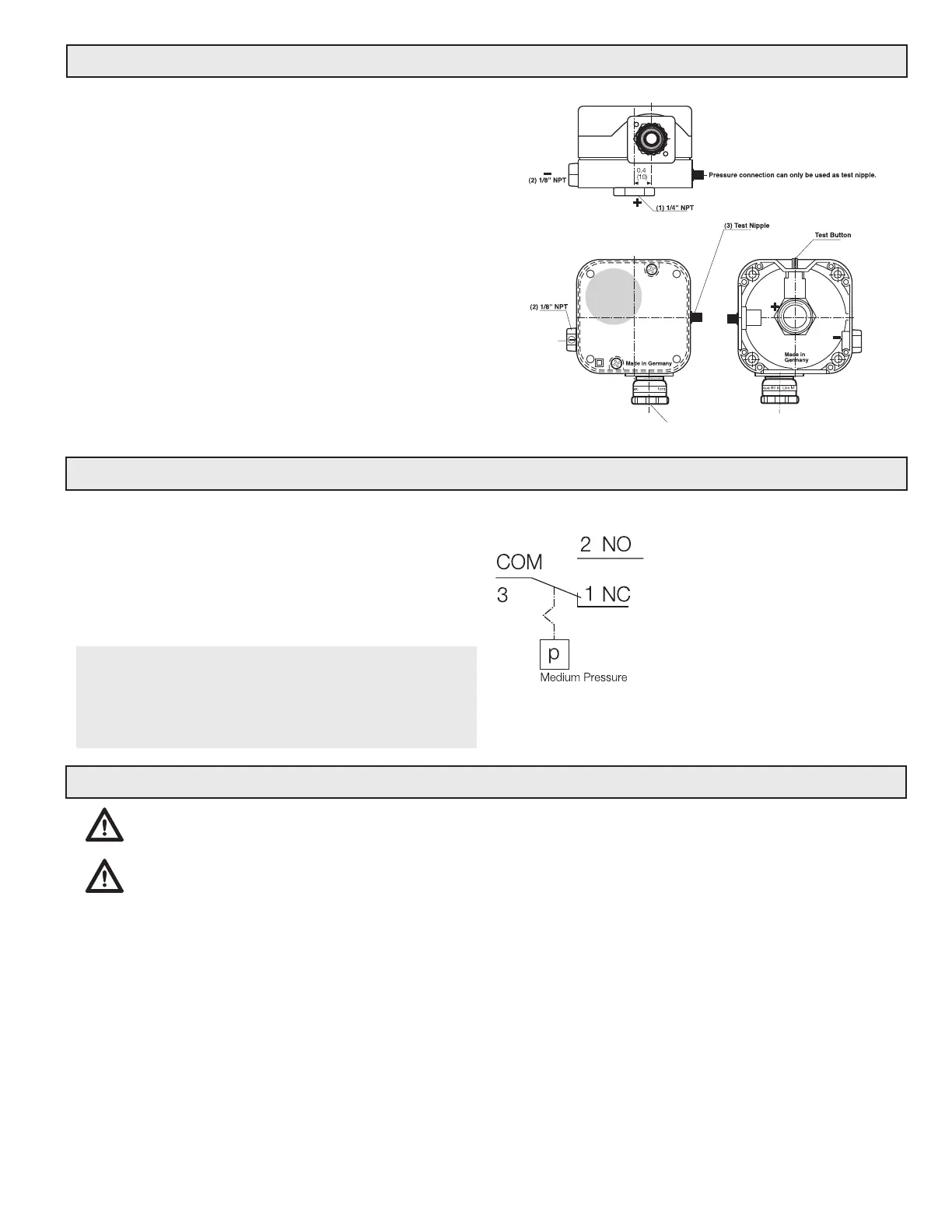

AA...A2-6 Threaded Connection

AA...A2-6 Mounting Procedure

• Apply good quality pipe sealant to the male threads only.

• Use 13/16” Wrench to secure the switch to the pipe.

DO NOT Exceed 45 lb-in of Torque on 1/8”

Connections

DO NOT Exceed 60 lb-in of Torque on 1/4”

Connections

• After installation is complete, perform a leak test.

Test button (for AA-A2-6 series only)

When the test button is pressed the 1/4” NPT pressure con-

nection is interrupted and the pressure below the diaphragm

is relieved. The pressure switch changes the contact position

from NO to NC. When the test button is released, the pressure is

built up again and the switch changes to its original position.

(1) Pressure connection (+)

(2) Pressure connection (–)

(3) Test nipple p (+)

PRESSURE CONNECTIONS AND MOUNTING AA..A2-6

Loading...

Loading...