14

General

Use piping materials and joining methods acceptable •

to authority having jurisdiction. In absence of such

requirements, follow National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

Size and install gas piping system to provide suffi cient •

gas supply to meet maximum input at not less than

minimum supply pressure. See Table 8.

Support piping with hooks, straps, bands, brackets, •

hangers, or building structure components to prevent or

dampen excessive vibrations and prevent strain on gas

connection. Boiler will not support piping weight.

Use thread (joint) compound (pipe dope) suitable for •

liquefi ed petroleum gas.

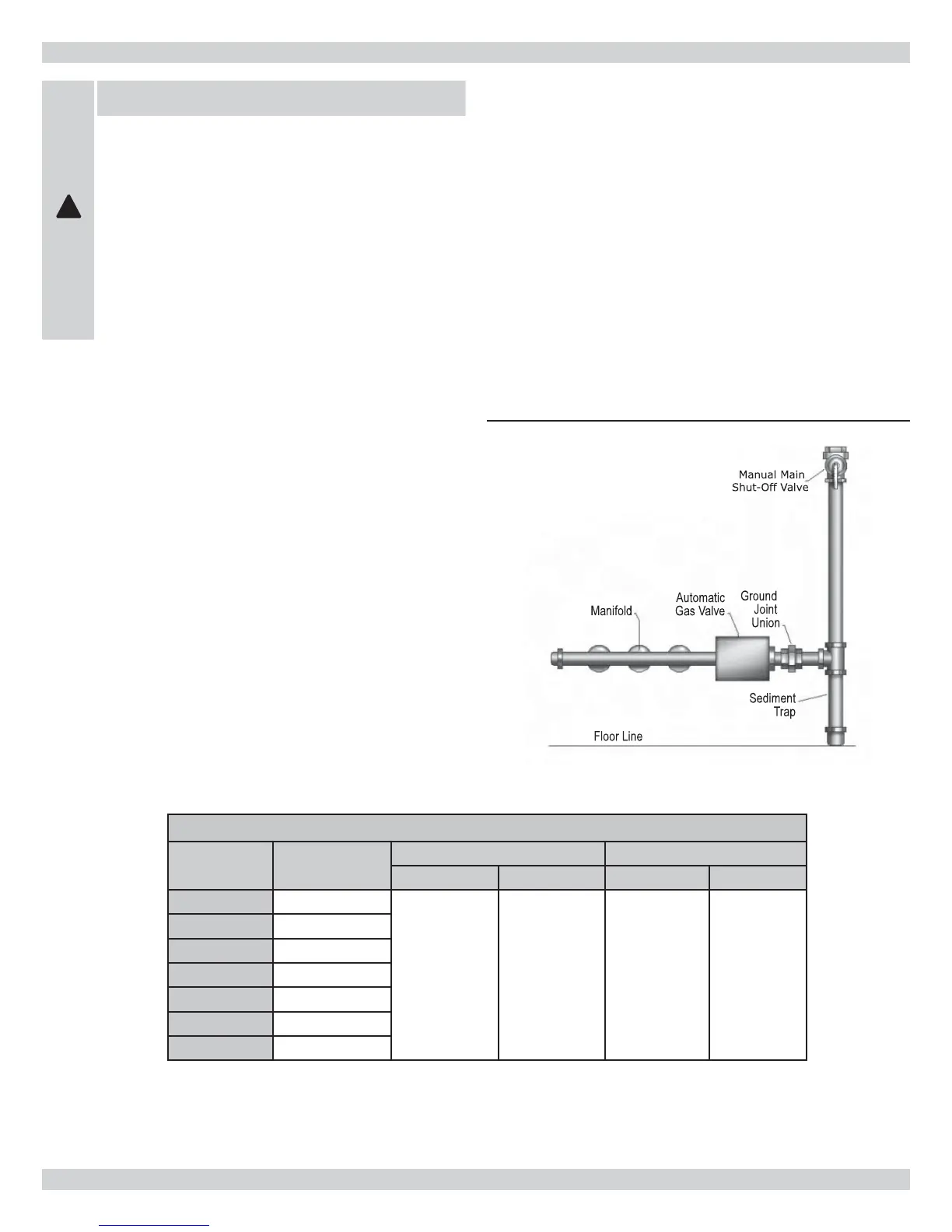

Provide sediment trap upstream of gas valve. See Figure •

15.

GAS SUPPLY PIPING

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.•

Do not touch any electrical switches; do not •

use any phone in your building

Immediately call your gas supplier from a •

neighbor's phone. Follow gas supplier's

instructions.

If you cannot reach your gas supplier, call •

the fi re department.

TABLE 8: GAS SUPPLY PRESSURE

SIZE

Maximum

Input (Btuh)

Natural Gas Propane

Min. Max. Min. Max.

3 Section 70,000

3.0" w.c.

(0.7 kPa)

13.5" w.c.

(3.3 kPa)

5.0" w.c.

(1.2 kPa)

13.5" w.c.

(3.4 kPa)

4 Section 105,000

5 Section 140,000

6 Section 175,000

7 Section 210,000

8 Section 245,000

9 Section 280,000

Figure 15 - Gas Piping At Boiler

Loading...

Loading...