DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

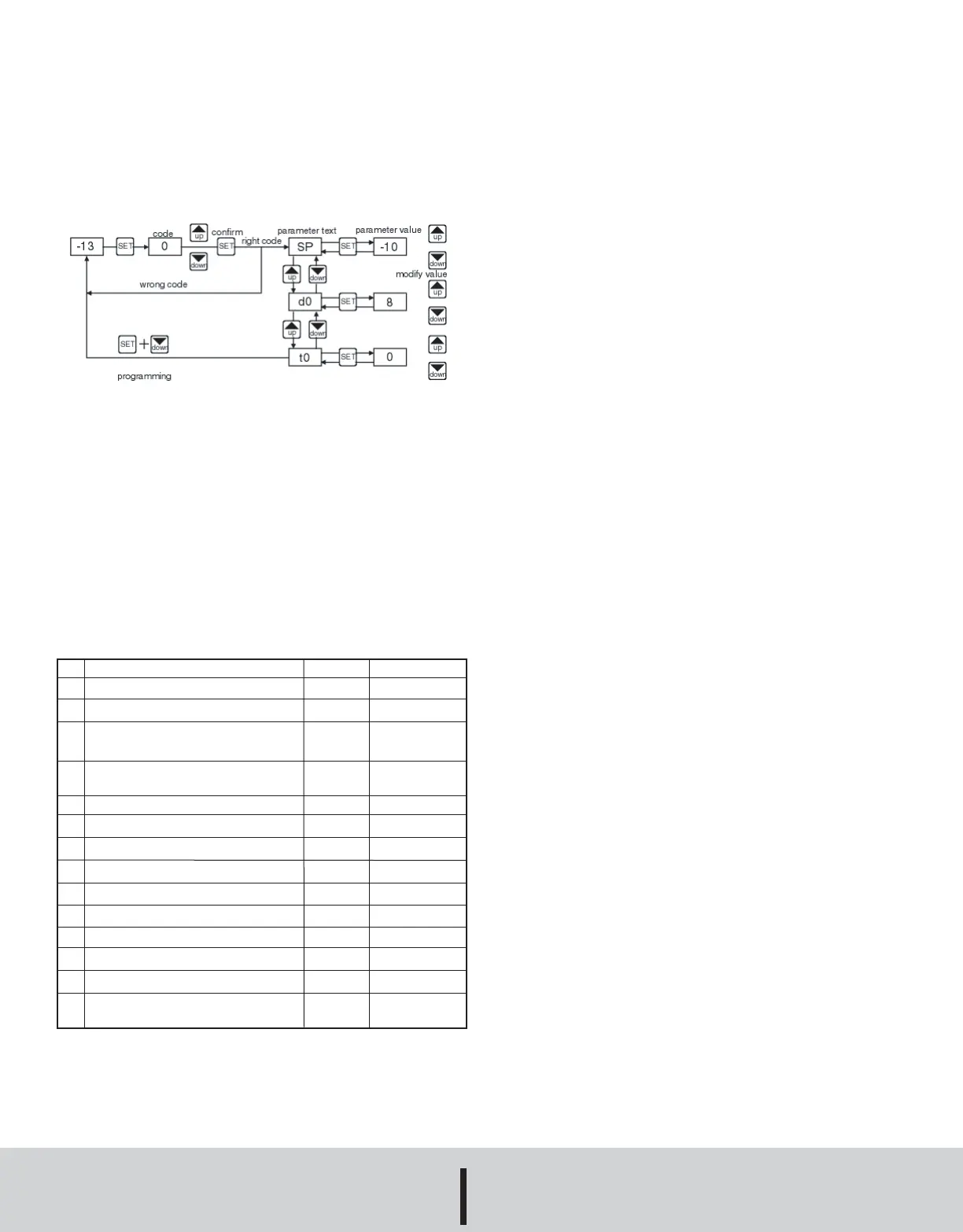

•Press SET to enter the code. If it is correct, the first parameter label will

be shown on the display (SP).

•Move to the desired parameter with the UP and DOWN keys.

•Press SET to see the value.

•Modify the value with the UP and DOWN keys.

•Press SET to enter it, and exit to text parameter.

•Press SET and DOWN to quit programming, or wait 1 minute for the

TIMEOUT.

SETTING THE KEYBOARD CODE TO ZERO

The keyboard code can be set to zero by holding the SET key and turn-

ing the controller off then on again.

LED INDICATIONS

Out: This indicates that the compressor is connected. It waits the pro-

grammed minimum stop time of the compressor.

Def: This indicates that defrosting is activated.

MESSAGES DISPLAY

In normal operation, the probe temperature will be shown. In case of

alarm or error, the following messages will be shown:

• Er- Memory error.

• -- Short-circuited probe error.

• oo- Open probe error.

PARAMETERS

PARAMETER DESCRIPTIONS

SP = Set Point. Temperature wished to regulate the machine. Can vary

from r1 to r2.

r0 = Differential. Heating: If temperature is ≥ Set then out OFF. If tem-

perature is ≤ Set then out OFF. Cooling: if temperature is > Set + r0 then

out ON. If temperature is ≤ Set then out OFF.

r1 = Lower Set Point Limit

r2 = Higher Set Point Limit

d0 = Heat or Cooling Control. Ht = heating control, Co = cooling con-

trol.

d2 = Defrosting Time Remaining, in minutes. If d2 = 0, defrosting will

not start.

d8 = Interval Between Two Defrostings, in hours.

c0 = Minimum time for compressor to be OFF. Minimum time from

when the compressor stops till it connects again.

c1 = Continuous Cycle Time. The remaining time for a continuous cold

cycle.

c2 = ON time of fault cycle, during probe error.

c3 = OFF time of fault cycle, during probe error.

P1 = Ambient Probe Calibration. Offsets degrees to adjust the ambient

probe.

H5 = Access Code to Parameters. Factory-set as 00.

t0 = Temperature Display Limit. Maximum temperature shown on the

display, although the real temperature can be greater.

OPERATION IN CASE OF ERROR

If the probe or thermostat memory should fail, the compressor will be con-

nected for 5 minutes ON then 5 minutes OFF.

MAINTENANCE

CLEANING

Clean the surface of the display controller with a soft, damp cloth. Never

use abrasive detergents, petrol, alcohol or solvents.

REPAIRS

After final installation of the TS Series Digital Temperature Switch, no rou-

tine maintenance is required. A periodic check of system calibration is rec-

ommended. The devices are not field repairable and should be returned

to the factory if recalibration or other service is required. After first obtain-

ing a Returned Goods Authorization (RGA) number, send the material,

freight prepaid, to the following address. Please include a clear

description of the problem plus any application information

available.

Dwyer Instruments,Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360 U.S.A

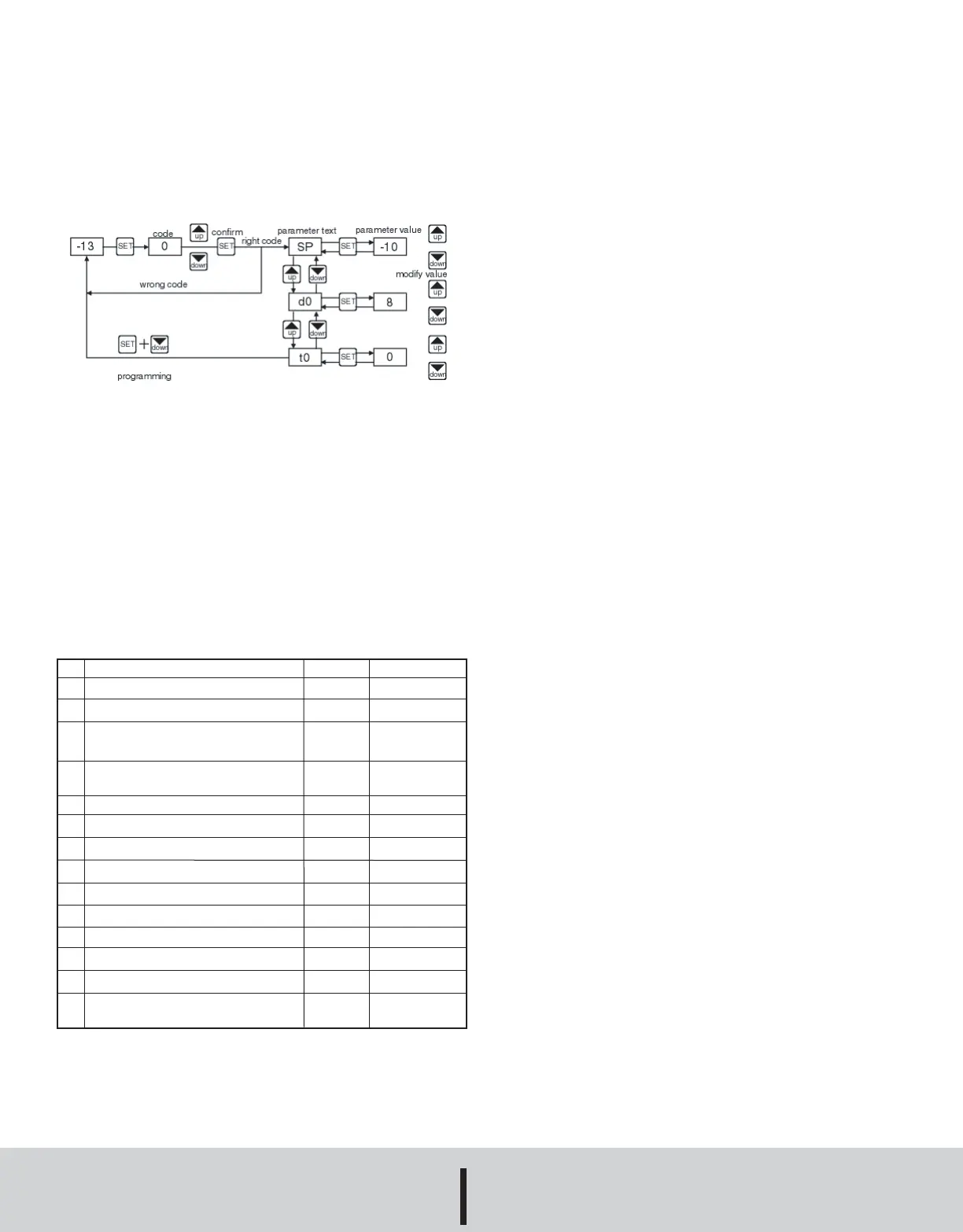

SP

r0

r1

r2

d0

d2

d8

c0

c1

c2

c3

P1

H5

t0

Description

Set point

Differential or hysteresis

Lower value for set point

Higher value for set point

Heating or cooling control

Time for defrosting

Interval time between defrosting

Minimum stop time for compressor

Continuous cycle time

ON time of fault cycle

OFF time of fault cycle

Ambient probe adjustment

Parameter access code

Maximum temperature on display

Units

degrees

degrees

degrees

degrees

option

minutes

hours

minutes

hours

minutes

minutes

degrees

numeric

degrees

Range

r1 to r2

1 to 20°

-50 to 150°C

-50 to 302°F

-50 to 150°C

-50 to 302°F

Ht/Co

0 to 59’

0 to 24

0 to 59’

0 to 24

0 to 999

0 to 999

-10° to 10°

0 to 99

-50 to 150°C

-50 to 302°F

exits

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 8/09 FR# R7-443771-00 Rev.1

T-TS2:TS2 Bulletin 8/13/09 12:00 PM Page 2

Loading...

Loading...