nection

almost

immediately.

Solder

should

then

be

applied

directly

to

the

parts

to

be soldered,

as

shown

in

the

middle

illustration

above,

and

both

iron

and

solder

removed

as

soon

as

the

solder flows freely.

When

soldering a part to the

etched

circuit board, the

solder

must

completely

surround the wire lead where it

comes through the board. Do not

apply

excessive solder, but

do not hesitate to

apply

sufficient heat to assure a

smooth

(low of solder all around the lead

and

onto the board.

, i

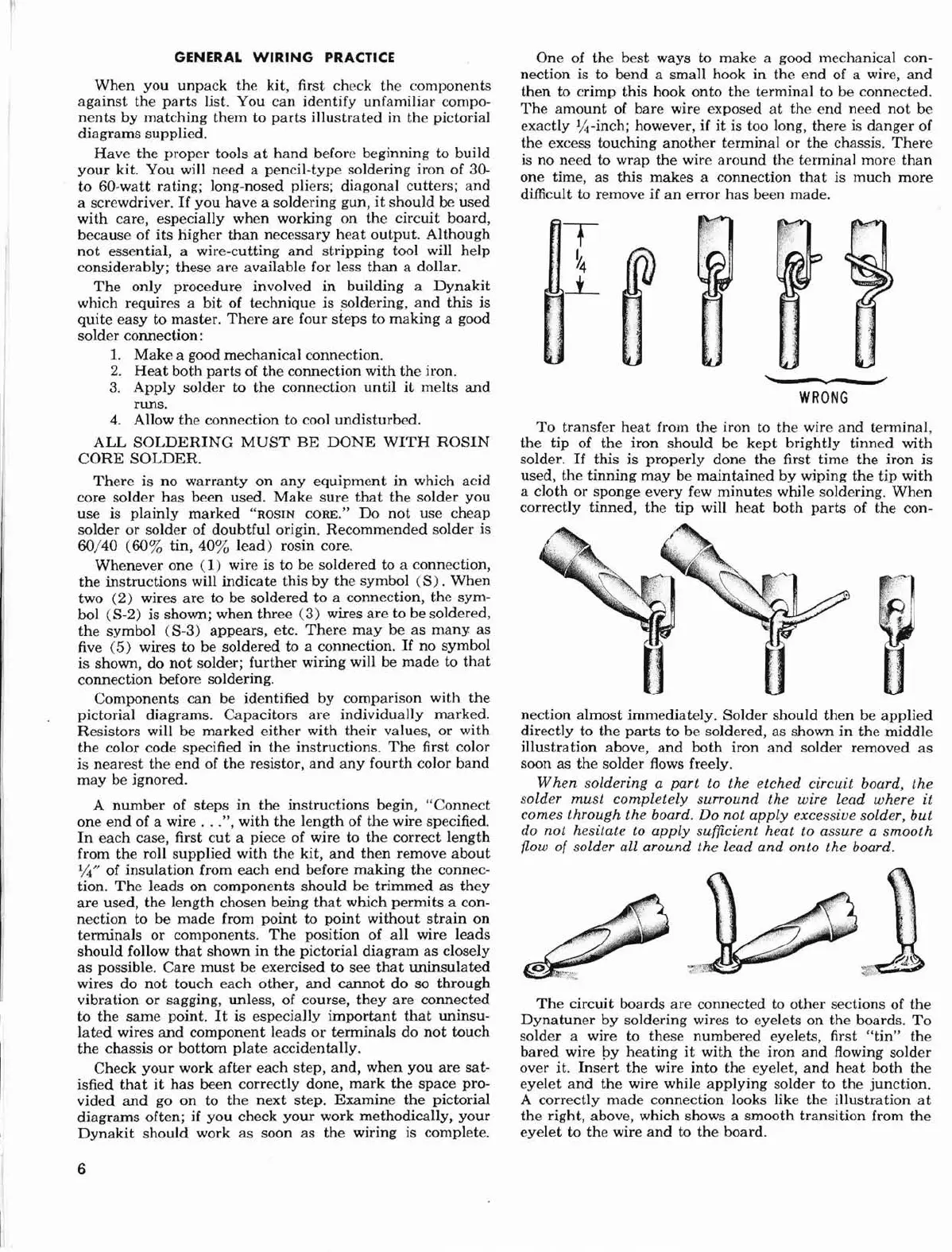

WRONG

One of

the

best

ways

to

make

a good mechanical con-

nection

is to

bend

a small

hook

in

the

end

of a wire,

and

then

to

crimp

this

hook

onto

the

terminal

to be connected.

The

amount

of

bare

wire exposed

at

the

end

need

not

be

exactly

11i-inch; however, if

it

is too long,

there

is

danger

of

the

excess touching

another

terminal

or

the

chassis.

There

is no

need

to

wrap

the

wire

around

the

terminal

more

than

one time,

as

this

makes

a

connection

that

is

much

more

difficult to remove

if

an

error

has

been made.

To

transfer

heat

from

the

iron to

the

wire

and

terminal,

the

tip of

the

iron

should

be

kept

brightly

tinned

with

solder.

If

this is

properly

done

the

first

time

the

iron

is

used, the

tinning

may

be

maintained

by

wiping

the

tip

with

a cloth

or

sponge

every

few

minutes

while soldering.

When

correctly

tinned,

the

tip

will

heat

both

parts

of

the

con-

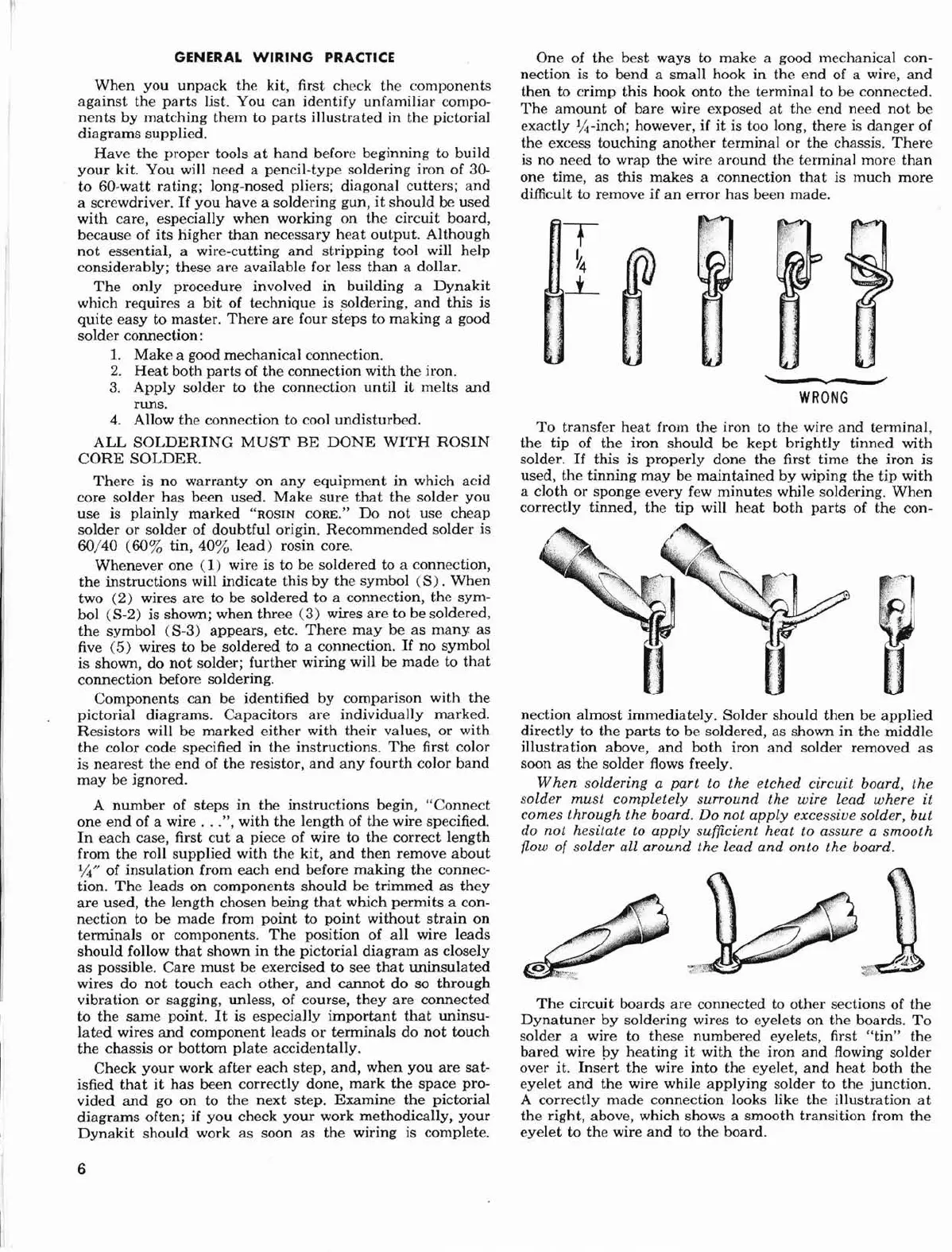

The

circuit

boards

are

connected to

other

sections of

the

Dynatuner

by

soldering wires

to

eyelets

on

the

boards.

To

solder

a wire to

these

numbered

eyelets, first

"tin"

the

bared

wire

py

heating

it

with

the iron

and

flowing solder

over it.

Insert

the

wire into the eyelet,

and

heat

both

the

eyelet

and

the

wire while

applying

solder to

the

junction.

A

correctly

made

connection looks like

the

illustration

at

the

right, above, which shows a

smooth

transition

from

the

eyelet

to

the

wire

and

to

the

board.

GENERAL

WIRING

PRACTICE

When

you

unpack

the

kit, first check

the

components

against

the

parts

list. You

can

identify

unfamiliar

compo-

nents

by

matching

them

to

parts

illustrated

in the pictorial

diagrams

supplied.

Have

the

proper

tools

at

hand

before beginning

to

build

your

kit.

You

will

need

a

pencil-type

soldering iron of 30-

to

60-watt rating; long-nosed pliers; diagonal

cutters;

and

a screwdriver.

If

you

have

a soldering gun,

it

should

be

used

with

care, especially when working

on

the

circuit

board,

because of its

higher

than

necessary

heat

output.

Although

not

essential, a wire-cutting

and

stripping

tool will

help

considerably;

these

are

available

for less

than

a dollar.

The

only

procedure

involved

in

building a

Dynakit

which

requires

a

bit

of technique

is

soldering,

and

this

is

quite

easy

to

master.

There

are

four

steps

to

making

a good

solder

cOTU1ection:

1.

Make

a good

mechanical

connection.

2.

Heat

both

parts

of

the

connection

with

the

iron.

3.

Apply

solder

to

the

connection

until

it

melts

and

runs.

4. Allow

the

connection

to coo)

undisturbed.

ALL

SOLDERING

MUST

BE

DONE

WITH

ROSIN

CORE

SOLDER.

There

is

no

warranty

on

any

equipment

in

which acid

core solder

has

been

used.

Make

Sure

that

the

solder

you

use is

plainly

marked

"ROSIN

CORE."

Do

not

use

cheap

solder

or

solder

of

doubtful

origin.

Recommended

solder

is

60/40

(60%

tin,

40%

lead)

rosin core.

Whenever

one

(1)

wire

is

to

be

soldered

to a connection,

the

instructions

will

indicate

this

by

the

symbol

(S).

When

two

(2)

wires

are

to

be

soldered

to

a connection,

the

sym-

bol (S-2) is shown;

when

three

(3)

wires

are

to be soldered,

the

symbol

(S-3)

appears,

etc.

There

may

be

as

many

as

five

(5)

wires

to

be

soldered

to a connection.

If

no

symbol

is shown,

do

not

solder;

further

wiring will be

made

to

that

cOTU1ection

before soldering.

Components

can

be identified by comparison

with

the

pictorial diagrams.

Capacitors

are

individually

marked.

Resistors

will be

marked

either

with

their

values,

or

with

the color code specified

in

the

instructions.

The

first color

is

nearest

the

end

of

the

resistor,

and

any

fourth color

band

may

be ignored.

A

number

of

steps

in

the

instructions

begin,

"Connect

one

end

of a wire

...

",

with

the

length

of

the

wire specified.

In

each

case, first

cut

a piece of wire to

the

correct

length

from

the

roll

supplied

with

the

kit,

and

then

remove

about

114/1

of

insulation

from

each

end

before

making

the

connec-

tion.

The

leads

on

components

should

be

trimmed

as

they

are

used,

the

length

chosen being

that

which

permits

a con-

nection to be

made

from

point

to

point

without

strain

on

terminals

or

components.

The

position of

all

wire

leads

should

follow

that

shown

in

the

pictorial

diagram

as

closely

as

possible.

Care

must

be exercised to see

that

uninsulated

wires

do

not

touch

each

other,

and

cannot

do

so

through

vibration

or

sagging, unless, of course,

they

are

cOTU1ected

to

the

same

point.

It

is especially

important

that

uninsu-

lated

wires

and

component

leads

or

terminals

do

not

touch

the

chassis

or

bottom

plate

accidentally.

Check

your

work

after

each

step,

and,

when

you

are

sat-

isfied

that

it

has

been correctly done,

mark

the

space

pro-

vided

and

go

on

to

the

next

step.

Examine

the

pictorial

diagrams

often; if

you

check

your

work methodically,

your

Dynakit

should

work

as

soon

as

the

wiring is complete.

6

Loading...

Loading...