30 31

SC-14

SETTING UP YOUR FIREWOOD PROCESSOR

Read and understand this entire section for proper and safe

set up.

To set up the rewood processor conveyor, follow these steps:

1. Lower it with the hand winch (or electric winch if upgrade

applies) until wheels touch the ground, remove the belt pin.

!

SC-14 • SET UP

SC-14

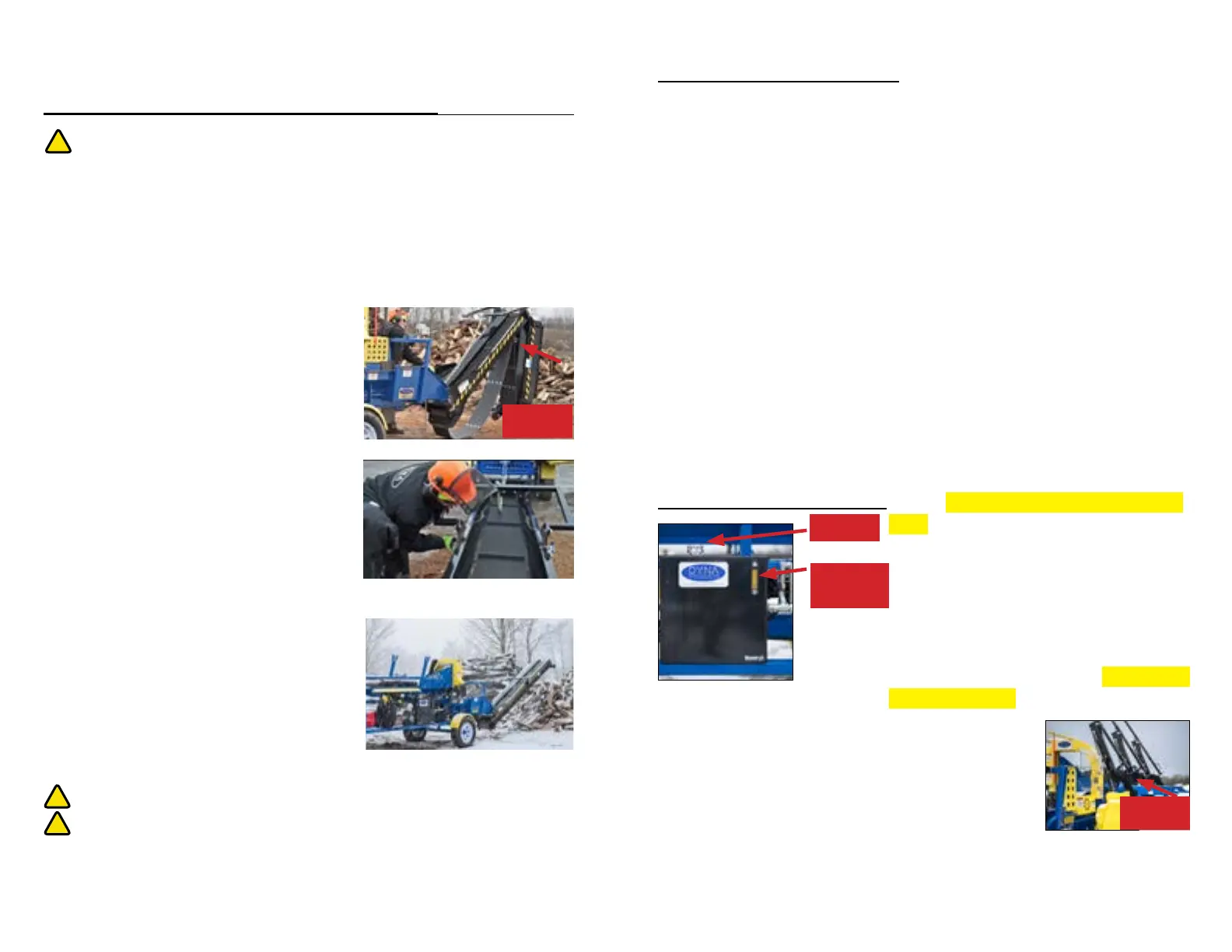

Fig. 1

Fig. 2

Fig. 3

2. Pull pin holding conveyor belting

out then use winch to lower front

section of conveyor at out. See

Fig 1.

3. Snap the locks on both sides of

conveyor securely into place. See

Fig 2.

4. Raise the conveyor to a

convenient height. See Fig 3

Then fasten the safety chain.

5. Lower stabilizer leg to the lowest

hole, then lower the jack until you

have weight on both legs.

NEVER stand underneath the conveyor.

ALWAYS USE SAFETY CHAIN ON CONVEYOR!

!

!

THE KOHLER GAS ENGINE:

Can be safely operated at 3700 rpm. This is typically set at the

factory. The engine should be choked for approx 5 seconds.

If you are running a diesel please refer to the CAT manual

provided. The choke pull is beside the throttle pull.

The oiler must be turned on at all times. There are 2 options

for oilers on the SC-14. The standard oiler pulls oil from

the hydraulic tank. There will be a knob on the power block

to control the oil ow on a machine that is oiling from the

hydraulics, this must be turned one 1/4 of a turn. You should

see oil dripping o the chain sprocket. The bar should be getting

enough oil to prevent discoloring from overheating. If you get

excessive oil, you may experience a spray or mist hitting the

operator. This indicates too much oil. The system will apply oil

every time the saw bar is coming down. You will need to watch

the oil level. You may need to add several quarts per day. The

second option is a dedicated oiler. The oil reservoir is on the

back shield with the oil pump below. The control is on the oiler

pump.

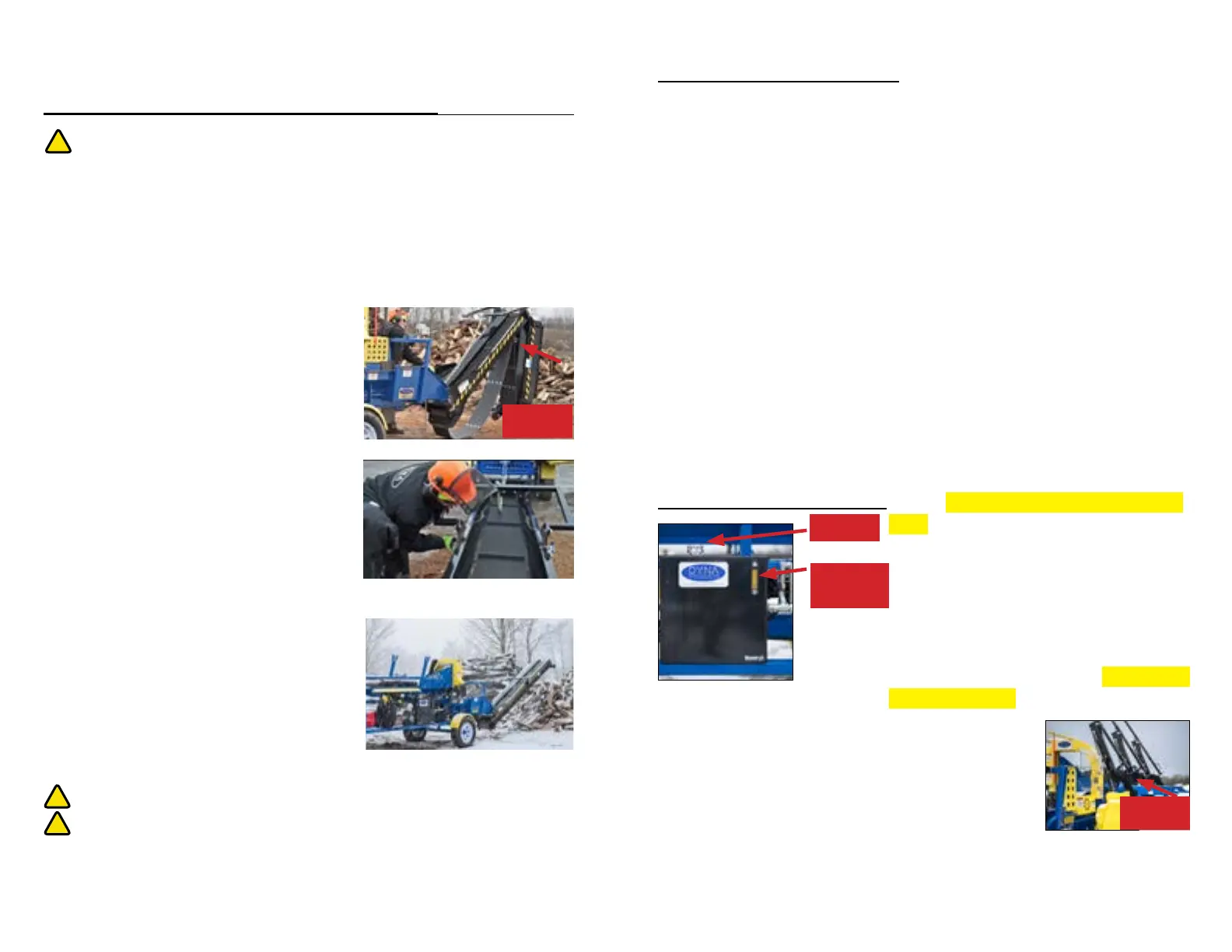

THE HYDRAULIC SYSTEM uses a standard 46 weight hydraulic

uid. Check the oil level daily. It

should always be in between the

high and low marks on the level

gauge. The temperature gauge

is also on the level. It should not

exceed 180 degrees Fahrenheit.

Running in excess could damage

the hydraulic system. The tank holds

25 gallons of oil and can be lled by

opening the cap on the top, see Fig 5 check the

level before you run the machine.

The log deck needs to be lowered before the

logs can be placed on top. These are serious

pinch points and can cause serious injury, see

Fig 6. The legs must be dropped to the

ground

or set on blocks and pinned into place.

SC-14 • SET UP CONT’D

Fig. 5

Oil Level

& Temp

Oil Filler

Oil Cap

Fig. 6

Pinch

Points

30

Remove

Pin

Oil Level

& Temp

Loading...

Loading...