32

SC-14

After the wood exits the splitter, it will push

out onto the conveyor (if supplied).

The conveyor may be turned on by

the control knob (see g. 9. The speed

may also be varied by this valve. The

conveyor can be adjusted for height

with the hand winch. Always be sure to

stay out from under the conveyor at all

times.

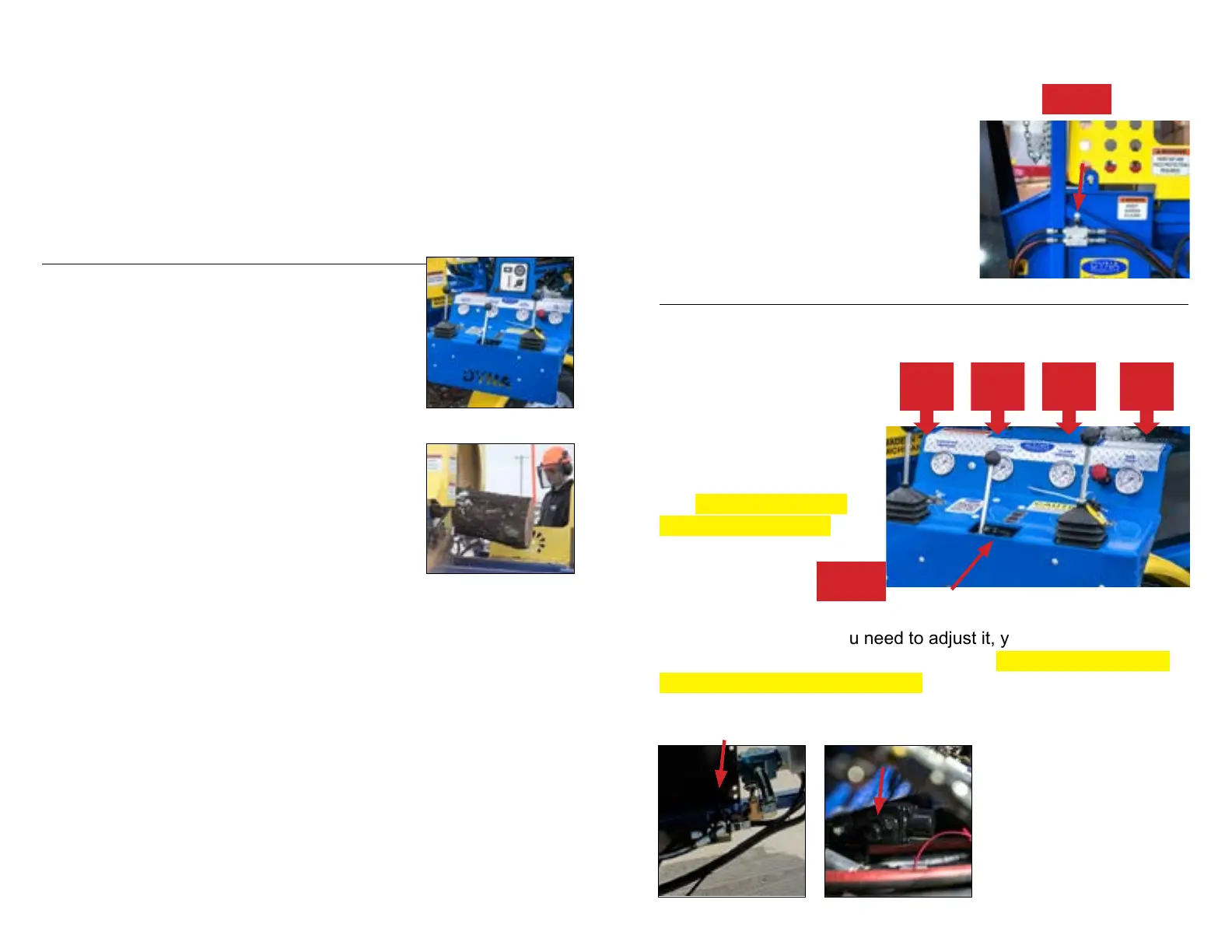

HYDRAULIC ADJUSTMENTS

The hydraulic pressures can be monitored by the gauge on the

control panel, see Fig. 10. The relief valve pressures always adjust

higher by turning clockwise

or tight. The relief valve

has a cap that needs to be

turned o and a jam nut

that needs to be loosened

before adjusting.

The conveyor pressure

should read 1250 psi. To

test this pressure, raise

the clamp and hold it while

reading.

This is not a critical

pressure, but in case you need to adjust it, you must adjust the

relief valve behind the oil tank, see Fig 11. The Splitter Pressure

should read 2800 psi to 3000 psi. You can get that reading by

stalling the splitter cylinder in the retract (home) position. To adjust

the detent on the splitter valve retract loosen the jam nut and turn

the adjustment bolt in to

hold tighter. See Fig 12.

Fig. 9

The logs can now be loaded onto the log deck. It works best to

keep the row of logs single without piling them on top of each

other. ALWAYS keep out from under the logs on the deck. They

could drop and cause serious injury. Never load logs from the

engine side of the machine.

OPERATING THE MACHINE

The logs can now be advanced toward the

in-feed trough and deposited one at a time.

The joystick controls have appropriate

instructions for the travel direction of the chains.

See Fig 7. Be sure to use only one function per

joystick simultaneously.

The log is brought into position to the orange

marker. See g 8.

Next, pull the lever for the clamp, when it is

clamped, the saw will automatically start and

travel through the log. The log will drop into the

splitter hopper and the lever must be pushed

the opposite direction to raise the saw. The

clamp will open when the saw reaches the up

position. The log is split using the middle splitter lever.

The 4-way wedge may be raised to the log’s center to maximize

the split. Be sure and keep the log centered across the wedge

especially with the 4-way wedge. NEVER split with excess log

mass on a horizontal wedge wing only. This causes excess fatigue

on the wing and can bend or break it. The warranty on the wedge

is voided if this happens.

While the splitter is returning, you may advance the log into

position again. You must never attempt to saw a log while the

splitter ram is in motion. These two functions should be operated

independently for best results. The splitter valve will automatically

snap into neutral when the cylinder bottoms out.

SC-14 • OPERATION

SC-14

Fig. 7

Fig. 8

SC-14 • OPERATION CONT’D

Fig. 10

Conveyor

Pressure

Splitter

Pressure

Clamp

Pressure

Sawfeed

Pressure

Fig. 11 Fig. 12

33

32

Conveyor

Control

Splitter

Relief

Loading...

Loading...