Installation, Operation and Service Manual LKAT

2

+24V

© 2018 DynAmp, LLC Page 22

046404 E

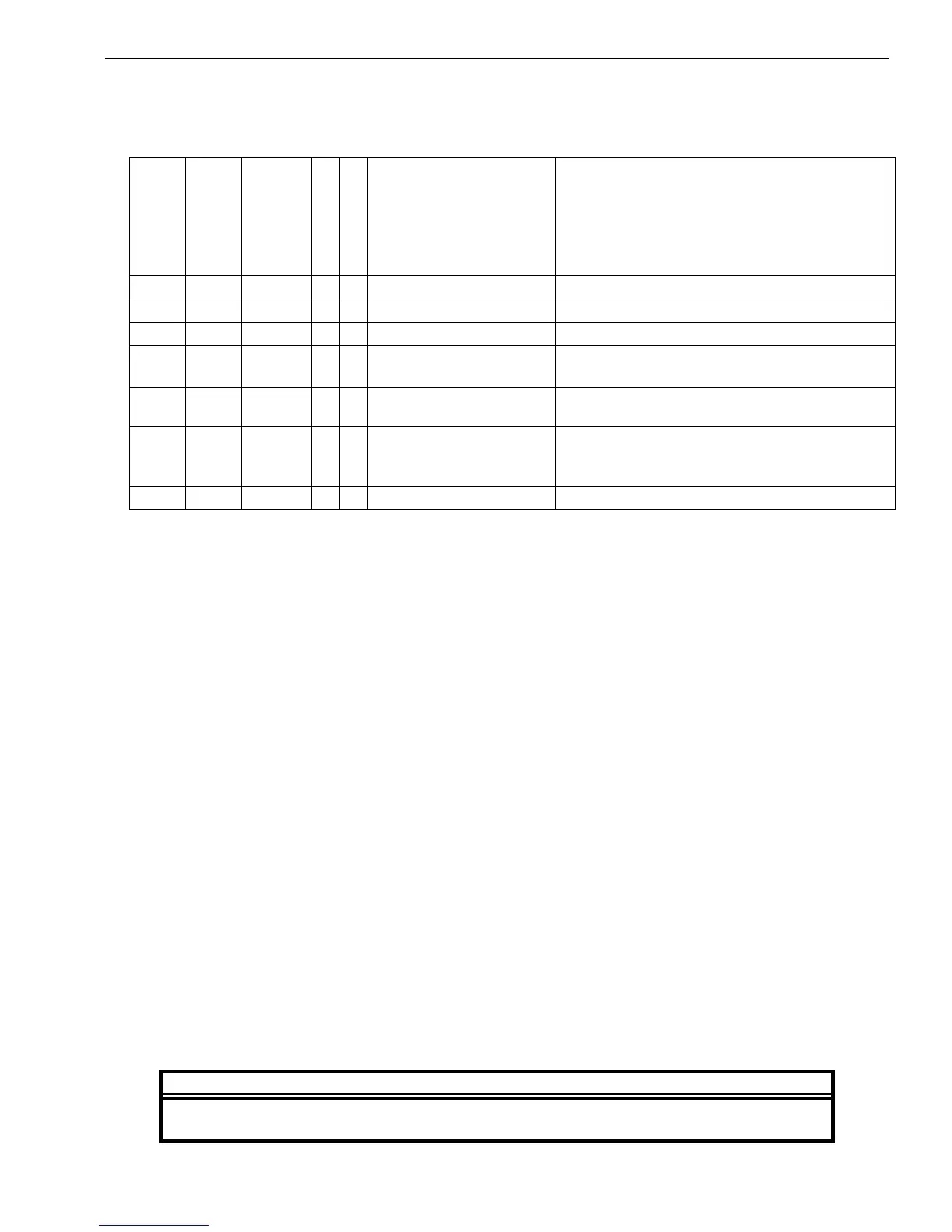

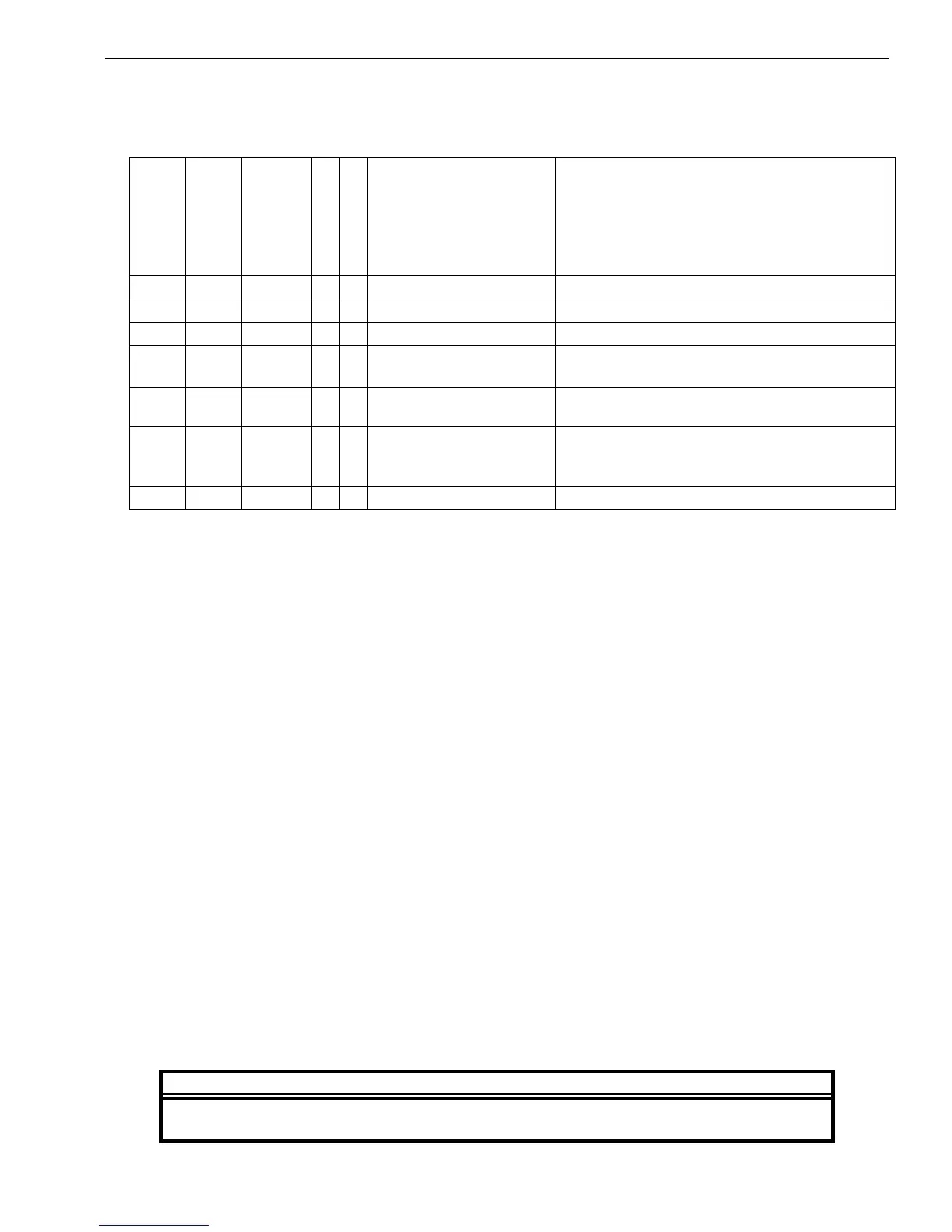

Table 5.1

Troubleshooting an Accuracy Diagnostics Fault Indication

Main

Green LED

Main

Red LED

Contact

P3-3 to P3-5

BUS ON

BUS OFF

Possible problem

Action / Check

Verify input power connection

Verify DC power on main PCB

OFF ON Closed X X

Verify head interconnections at Metering

Unit

OFF ON Closed X Head imbalance

Adjust position of head for green ON, red

OFF

OFF ON Closed X X

Measuring Head

malfunction

Measure head input signals at zero bus

current; output should be < 5mVdc;

substitute known good Measuring Head

5.7 SYSTEM CALIBRATION OVERVIEW

DynAmp does not specify exact required intervals of calibration for its products.

The end user of the product is responsible for identifying the appropriate interval between

calibrations. The intervals should be determined based on the following factors:

• Requirements of a Quality Management System

• Accuracy and permissible limits of errors

• Purpose and usage

• Experience with similar products

• Manufacturer’s recommendations

• Stability of the product

• Past history

• Other characteristics of the product

Reference: "ISO/IEC 17025:2017, General requirements for the competence of testing and

calibration laboratories" and Laboratory Accreditation Bureau "Guidance for Documenting and

Implementing ISO/IEC 17025:2005 and Laboratory Guidance."

As a guideline, DynAmp recommends a 24-month interval of calibration for all permanently

installed products and a 12-month interval of calibration for all products used in portable

applications.

Calibration may be performed as:

• Field Calibration (On Process Bus)

• Field Calibration (On Test Bus)

• Factory Calibration

DynAmp, LLC assumes no responsibility for the accuracy of LKAT

2

Systems calibrated

by any person other than a DynAmp, LLC Technician.

Loading...

Loading...