INSTRUCTIONS MANUAL – BR-BM

File: 4700367205_ENG_NO.doc Page 8 / 25

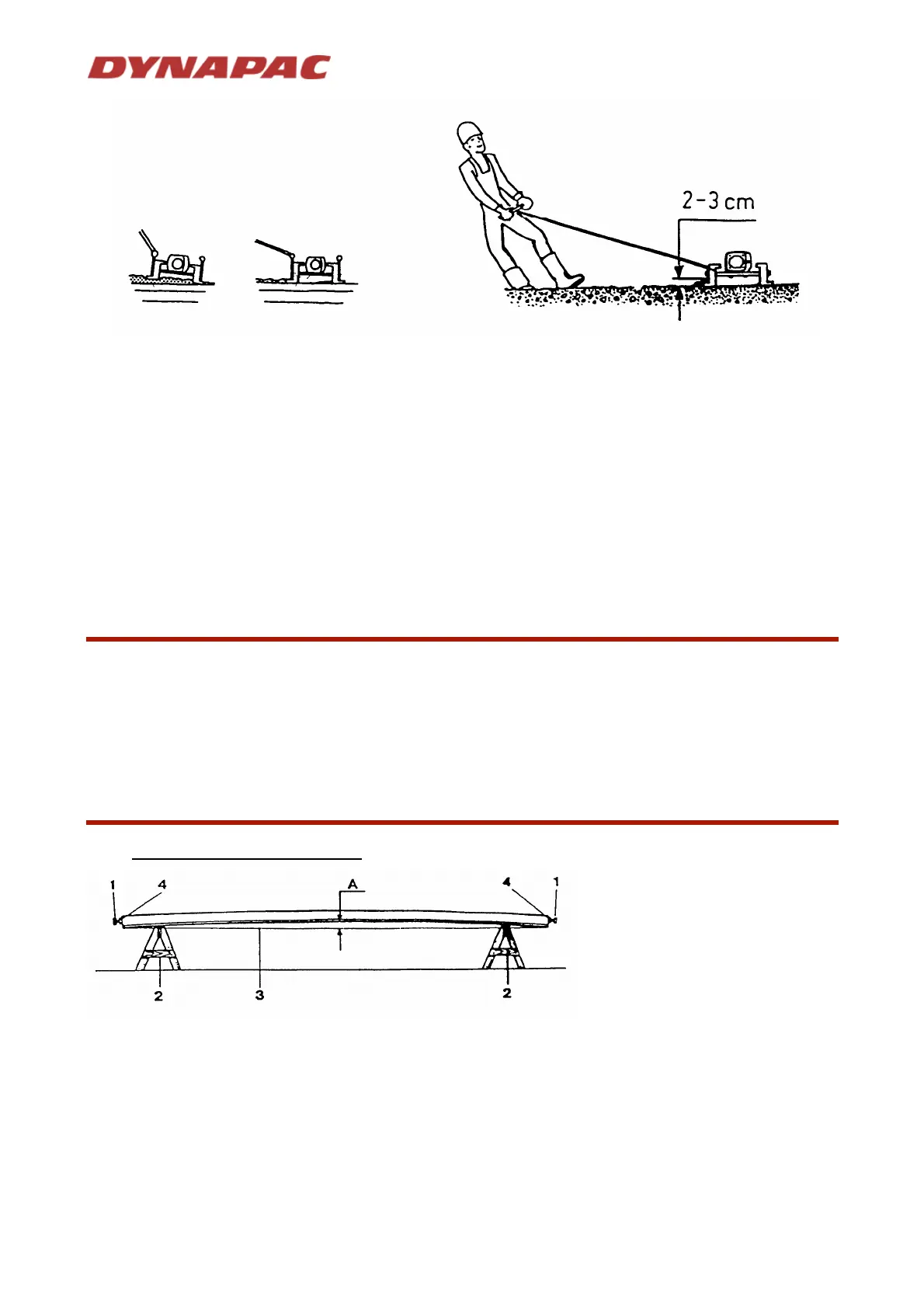

Wrong Right

The pulling cords on the double beam should not be too short as they will then cause the front of the

beam to tip up as shown in the above figure.

When reaching the end of the screeding section the vibrator should be switched of before the screeding

movement is stopped.

If a second screeding is to be carried out the beam must not be dragged back across the compacted surface

but should be carried back to the starting position.

MAINTENANCE

- Every day : Wash the beam and motor vibrator by hosing them down.

Never use high pressure cleaner.

- Every week : Check the tensioning height of the beam (see workshop instruction).

Oil the beam with form oil or Tectyl to facilitate cleaning it.

WORKSHOP INSTRUCTIONS

TENSIONNING

THE

BEAM

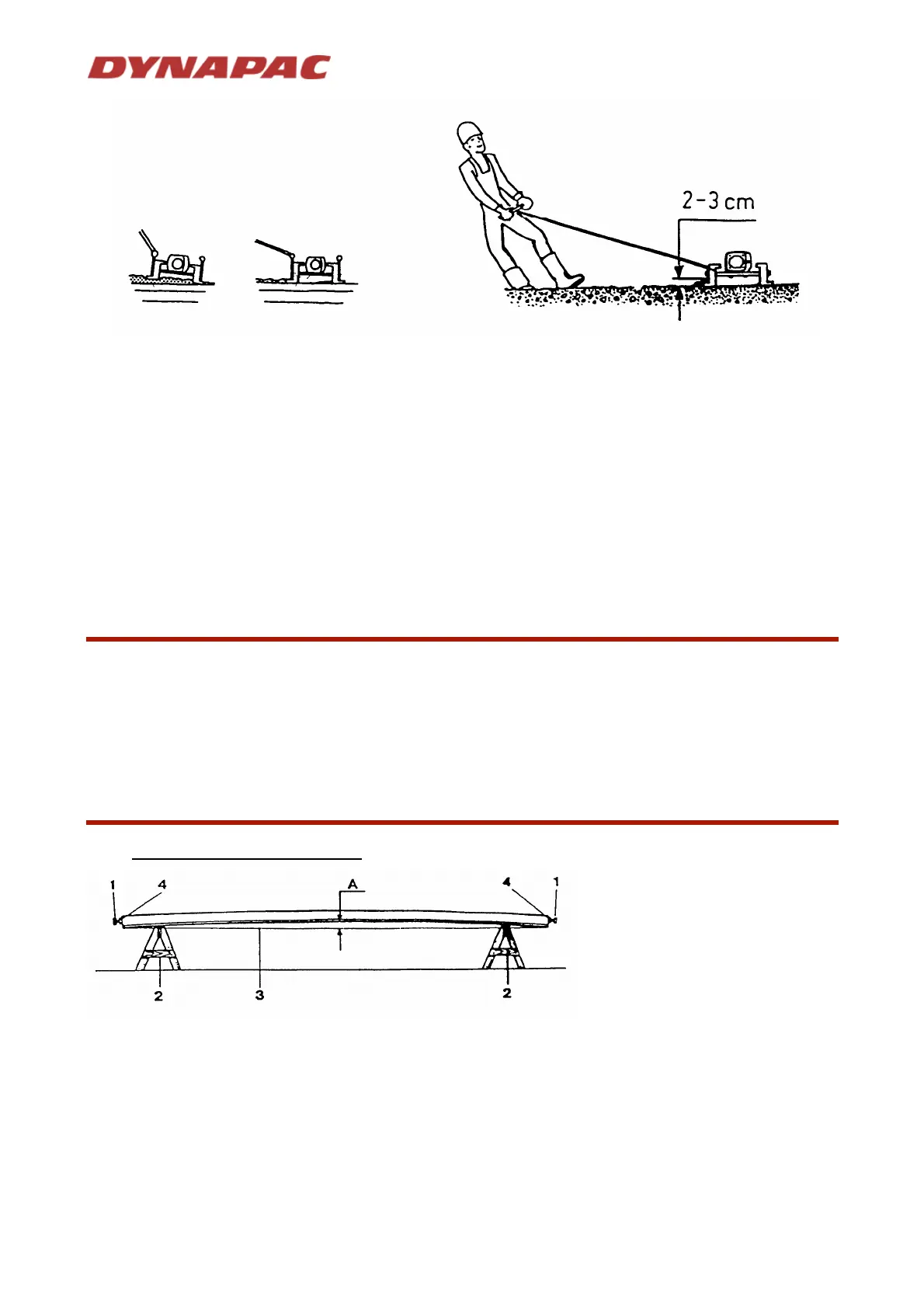

- Rest the ends of the beam on trestles 2. Using a spirit level, check that the trestles are horizontal.

- Back off the screws securing the vibrator bracket.

- Tension a piano wire 3 along the bottom of one beam section.

- Tension the beam by means of the tensioning screws 1.

Tighten the screws alternately. Measure the tensioning height "A" at the centre of the beam.

- Adjust the other beam section as described before.

- Check that the beam sections rest flat against the trestles.

If they do not, adjust the tensioning height by means of the tensioning screws 1.

- Tighten the locknuts 4 on the tensioning screws 1.

- Tighten the vibrator bracket retaining screws.

1. Tensioning screw

2. Trestle

3. Piano wire

4. Lock nut

A Tensioning height :

BM/BR 61-67 = 3 - 6 mm.

BR 68 = 4 - 8 mm.

Loading...

Loading...