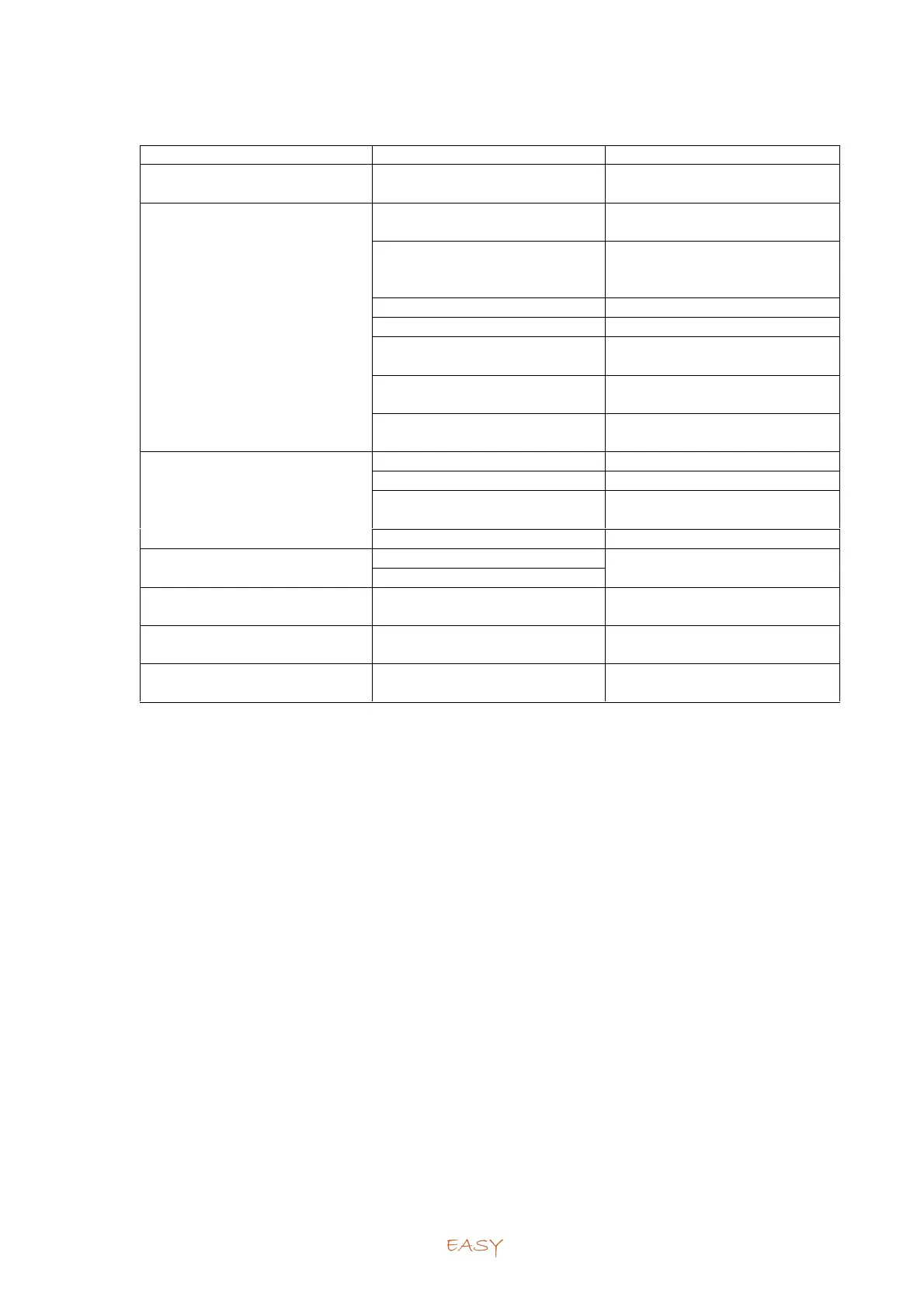

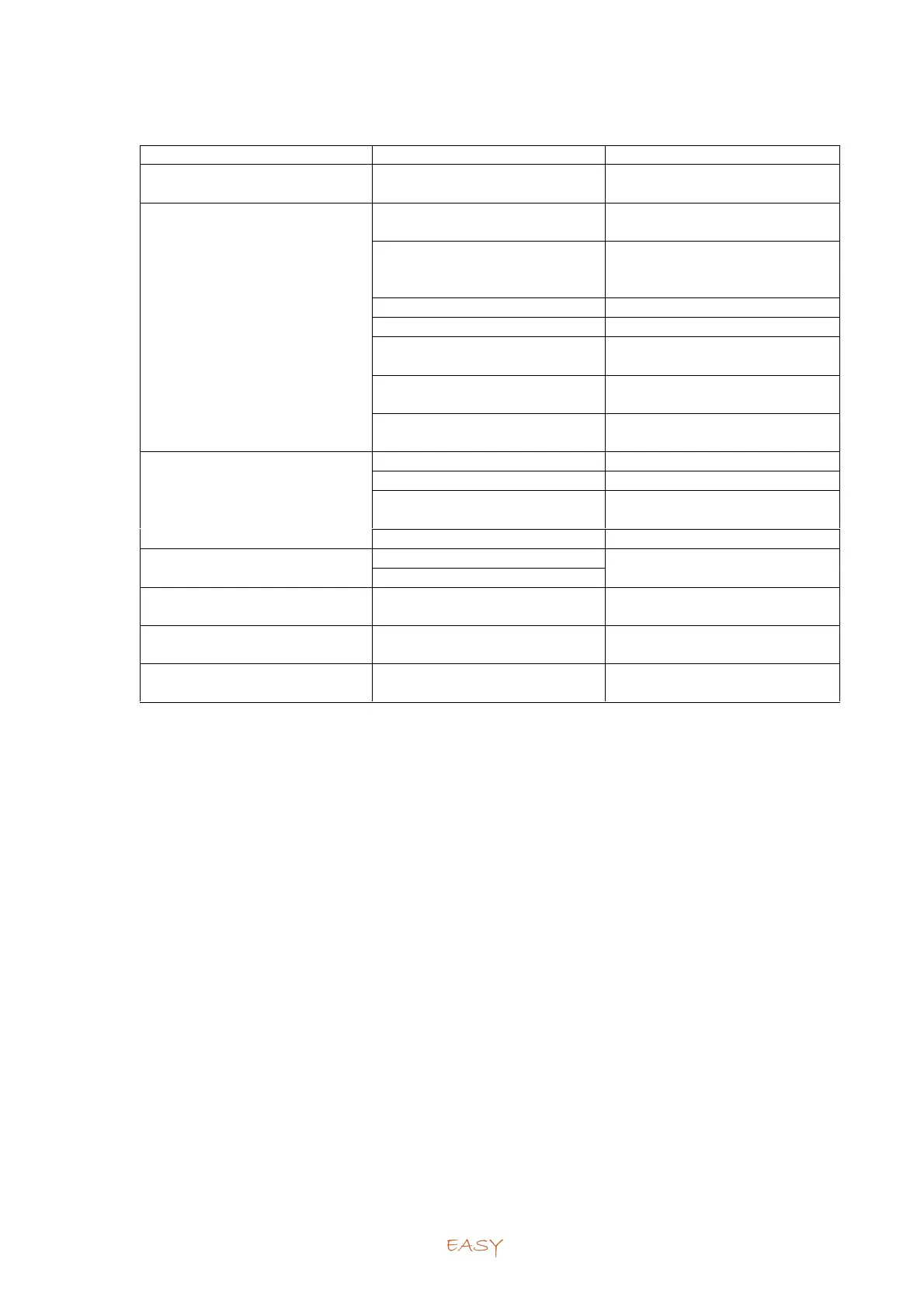

Droplets left inside the tip

Unsuitable tip, non-uniform wetting of

the plastic

Leakage or Pipetted volume too small

Tip holder (cone) scratched or

damaged

Organic solvent as liquid

Aspirate & discard the organic solvent

several times before actual pipetting

by the same tip

Foreign particles between tip and tip

cone

Insufficient amount of grease on piston

& O-ring

Clean & grease O-ring and piston

O-ring not correctly positioned or

damaged

Follow instructions carefully

Recalibrate according to instructions

Unsuitable for the particular liquid

pipetting technique

Use correct pipetting technique

Push button jammed or moves

erratically

Clean & Grease O-ring and piston

Penetration of solvent vapors

Tip ejector jammed or moves

erratically

Tip cone contaminated from outside

Remove ejector collar and clean tip

cone’s outer surface with ethanol

Volume setting is not properly click

stopped

Click stop mechanism damaged

Push button does not turn for volume

setting

Use of excessive force beyond the

range of pipette

Loading...

Loading...