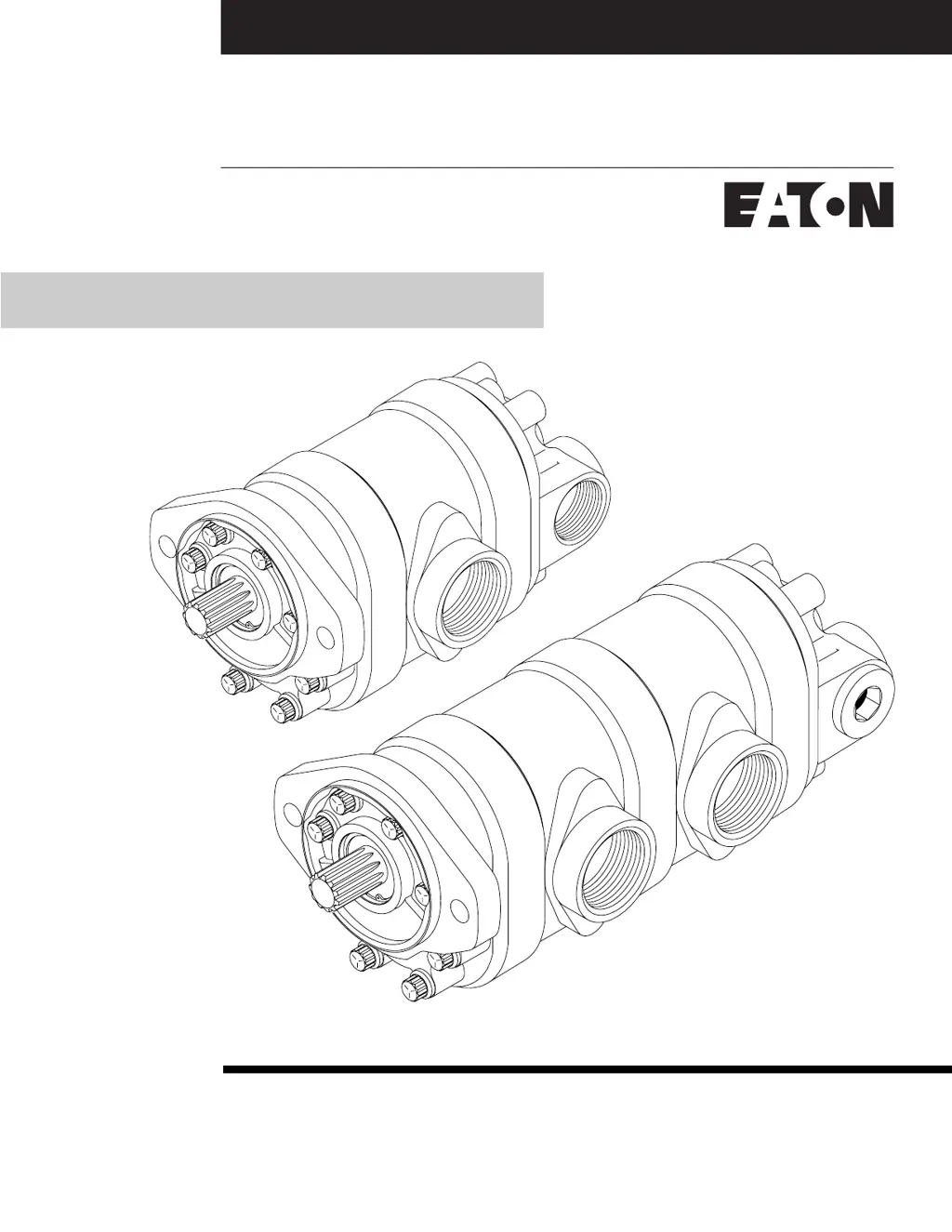

Why is the oil foaming in my Eaton 26 Series Water Pump?

- MMrs. Brandy RiosJul 28, 2025

If the oil in your Eaton Water Pump is foaming, it could be due to several reasons. First, check if the oil level is low and fill the reservoir if needed. Another possible cause is air leaking into the suction line; try tightening the fittings. Lastly, the issue might be the type of oil being used. In this case, drain the reservoir and refill it with non-foaming oil.