42 OPERATION AND INSTALLATION INSTRUCTIONS MN280075EN July 2018

Form 6 microprocessor-based rack-mount recloser control

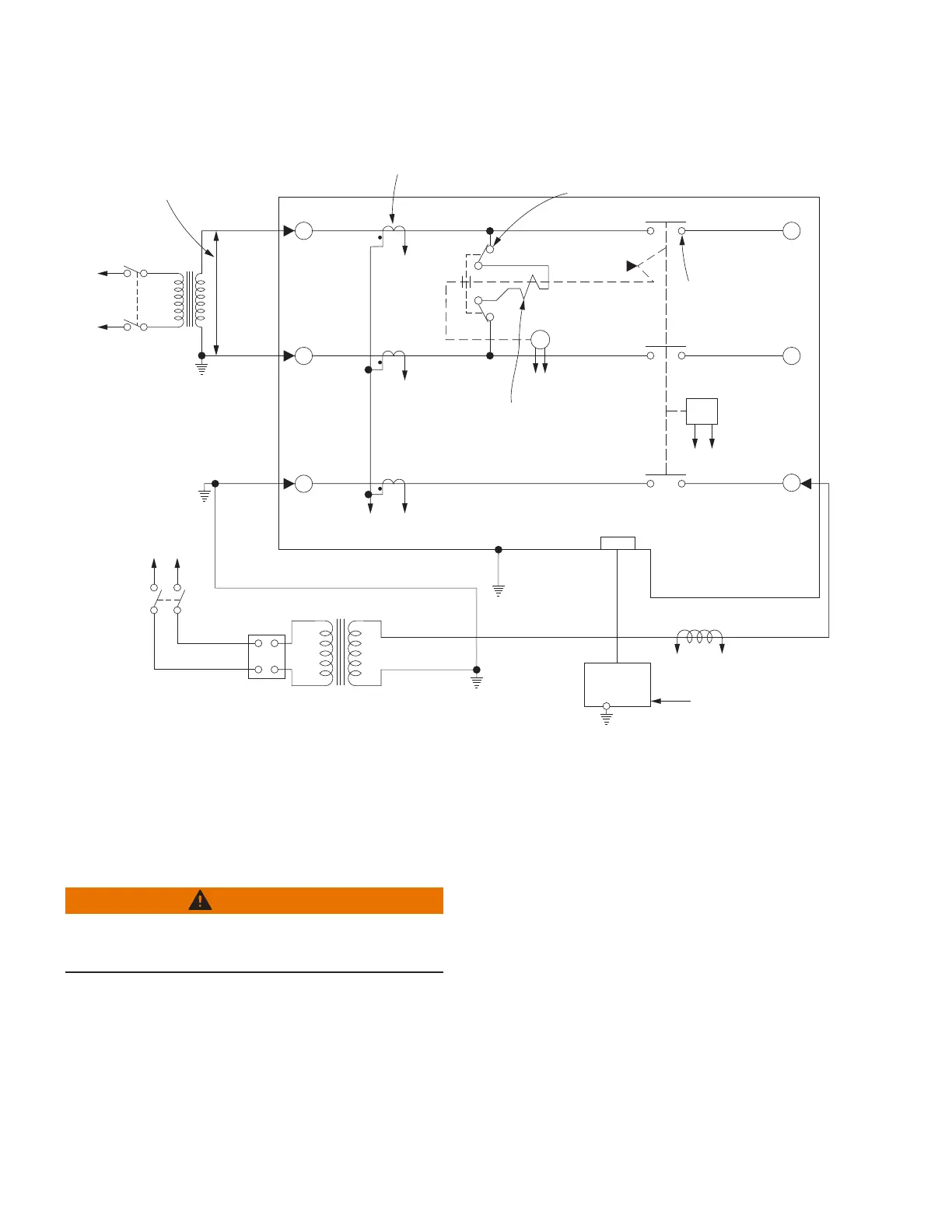

3

6

4

T3

Y

H*

X

Z

VOLTAGE RATING OF

RECLOSER CLOSING

SOLENOID COIL

SENSING CTs (3)

CLOSING

SOLENOID

CONTACTOR

ROTARY

SOLENOID

MAIN

CONTACTS (S)

G*K*

A* B*

E* F*

TO

240 OR

480 VAC

SOURCE

TO

240 VAC

SOURCE

CLOSING

SOLENOID

COIL

TRIP

SOLENOID

CONTROL

CABLE RECEPTACLE

W

FORM 6

CONTROL

TO

AMMETER AND RELAY TO

OPERATE CYCLE COUNTER

OR OTHER TIMING DEVICE

AC POWER

VARIABLE

AUTOTRANSFORMER

240 VAC

20 AMPS

T2

1

2

5

J*

T1

*Indicates control cable receptacle pin/socket designation.

Figure38. Suggested test circuit for high voltage “shop-testing” solenoid-closing reclosers

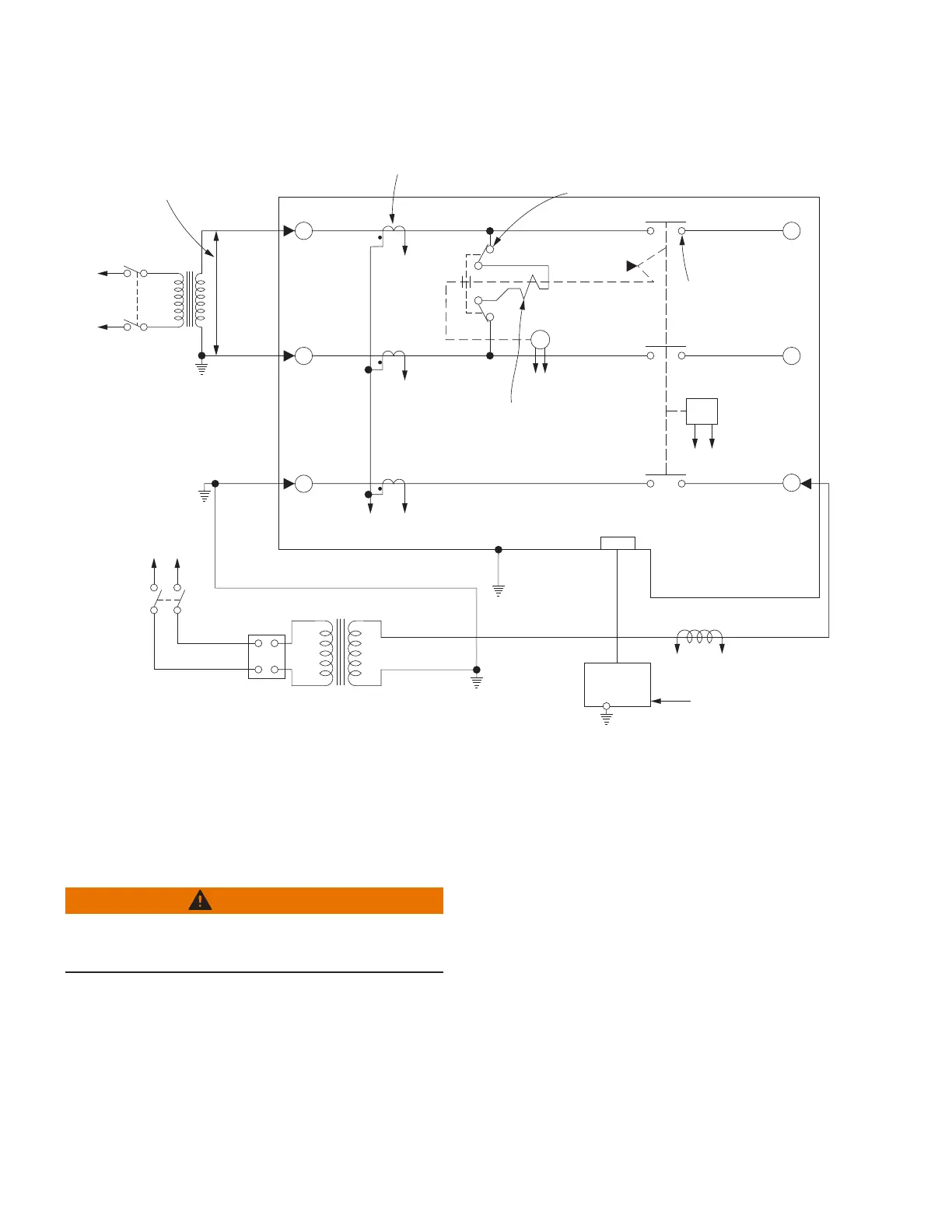

Electrical closing – motor-operated

low voltage closing solenoid / auxiliary-powered

NOVA reclosers

WARNING

Hazardous voltage. Solidly ground all equipment.

Failure to comply can result in death, severe personal

injury, and equipment damage. T223.2

High-voltage is not required for reclosers utilizing a

motor-operated closing mechanism, low voltage closing,

or Auxiliary-Powered NOVA recloser. For information on

energizing the recloser, refer to the appropriate recloser

installation manual. Low voltage supply can use either 120

or 240 VAC for input power. Check the name plate on the

recloser to verify the correct closing power requirements.

Figure39 shows a test circuit for motor-operated,

low-voltage solenoid-closing, and Auxiliary-Powered NOVA

reclosers. Since these reclosers require only a low voltage

source for closing, high-voltage transformer T3 and its

protective cage is eliminated. All other equipment is the

same as the test equipment shown in Figure38.

Loading...

Loading...