12 OPERATION AND INSTALLATION INSTRUCTIONS MN280075EN July 2018

Form 6 microprocessor-based rack-mount recloser control

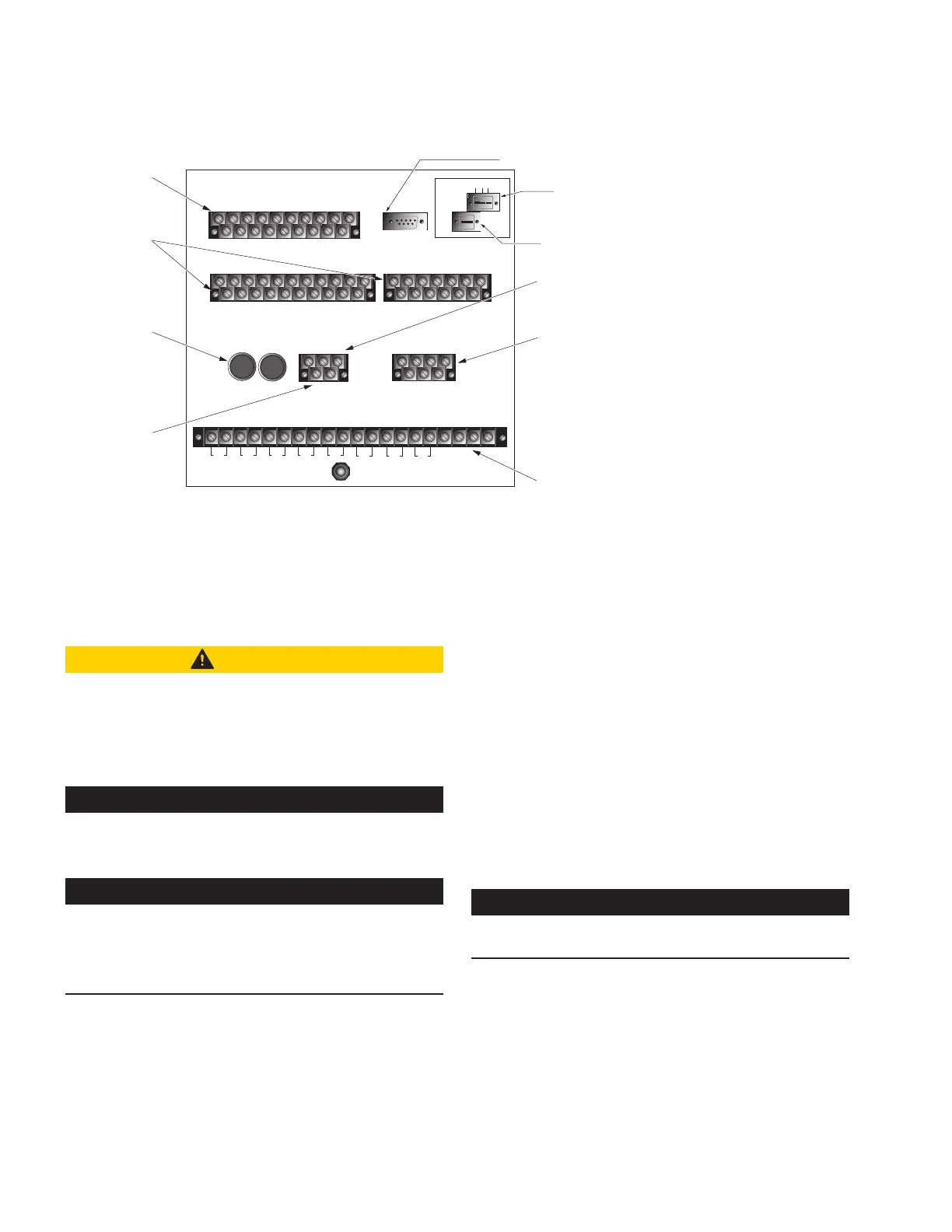

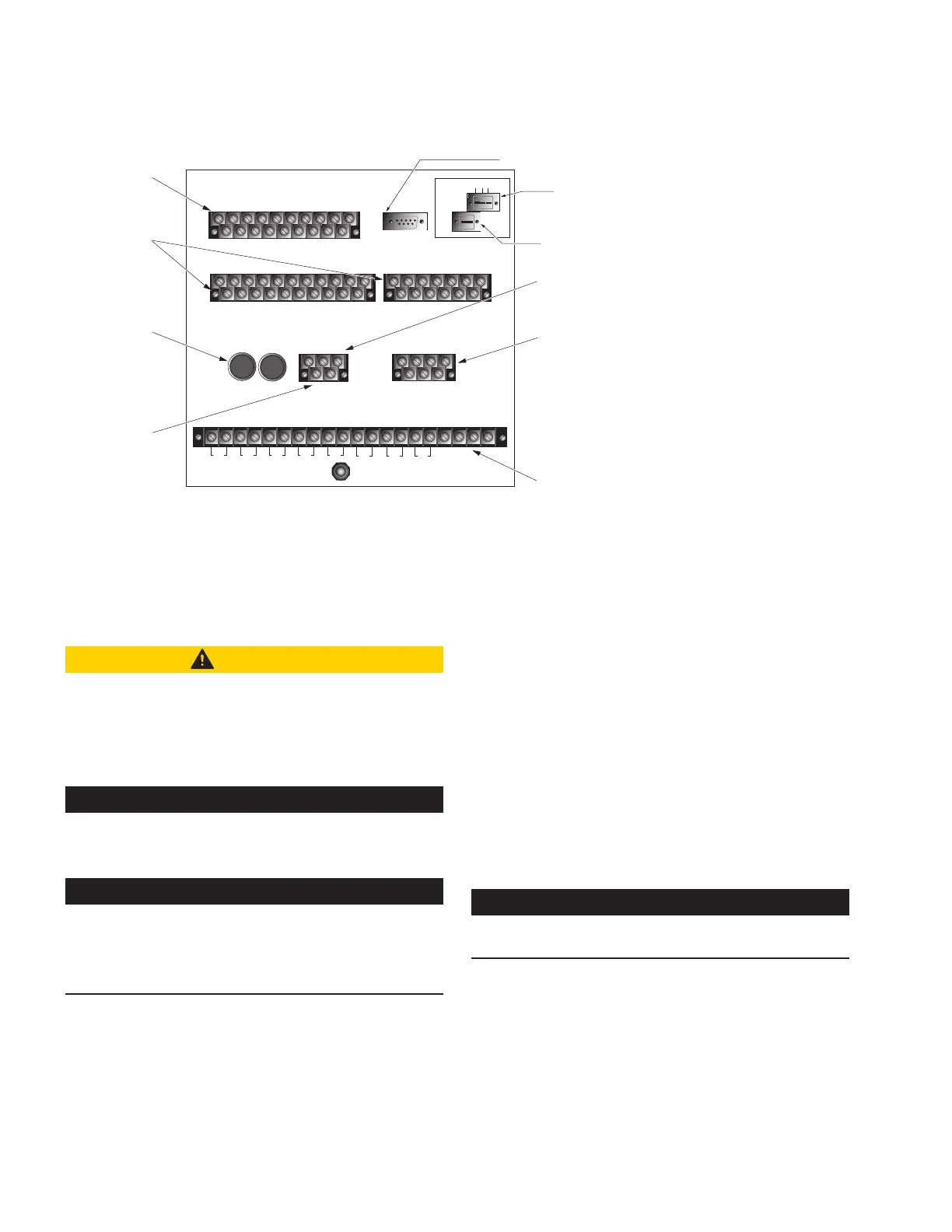

TB1

1

2

3 57911 13 15 17 19

46 81012141618

CI1

CI2 CI3 SS1 CO1

CO2 CO3 CO4

CI4

CI1 CI2 CI3 SS1 CO1 CO2 CO3 CO4

TB3

1

3

579111315171921

CI5 CI6 CI7 CI8 CI9 CI10 CI11 CO5 CO6

TB4

2

46 81012141618

20

CI4 CI5 CI6 CI7 CI8 CI9 CI10 CI11 CO5

CO6

13

5

7911 13

CO7 CO8

CO9 CO10 CO11

CO12

2

46 81012

CO7 CO8 CO9 CO10 CO11 CO12

FUSE

(10 AMP)

FUSE

(10 AMP)

TB5

+

1

-

5

2

-

4

+

INPUT POWER AUXILIARY POWER

28 VDC

RECLOSER INTERFACE CONNECTIONS

A

1

D

3

F

57

2

B

4

C

6

E

TB6

TB2

•

12

•

34

•

56

•

78

•

910

•

11 12

•

13 14

•

15 16

•

17 18

•

19

20

I

(1-2)

I(3-4) I(5-6) V(1-2)

V(3-4) V(5-6) V1

I(SEF)

Three Control Input

and Five Status

Output Contacts

(Standard Feature)

Eight Control Inputs

and Eight Status

Outputs (Accessory)

Fuses

125 VDC

10 Amp

VDC Power Input

Connections

28 VDC Auxiliary

Power Connections

Recloser Interface

Terminal Block

Analog Connections

Terminal Block for

Connecting to Recloser,

Voltage Inputs

J1-RS-232

IRIG-B

RS-485

RS-232 DTE

RS-232 Serial Communication Port

Fiber Optic port, "ST" Type Connector (optional),

Ethernet Port, "MT-RJ" Fiber RJ45 Connector (optional)

RS-485 Serial Communication Port (optional)

C + –

IRIG-B Time Sync Connector

Figure7. Rack mount control back panel

Installation procedure

Initial programming prior to installation

CAUTION

Equipment misoperation. Do not connect this control

to an energized recloser until all control settings have

been properly programmed and verified. Refer to the

programming information for this control. Failure to

comply can result in control and recloser misoperation,

equipment damage, and personal injury. G110.3

IMPORTANT

Equipment misoperation. Check minimum trip values prior

to changing an alternate profile. Failure to do so may cause

misoperation of the recloser under loadconditions. T280.1

IMPORTANT

Program all protection profiles. Unused alternate profiles

should be programmed with the same settings as one of

the applicable profiles. Default settings on unused alternate

profiles can cause unnecessary outages if they are below

normal system requirements.

The control must be programmed with all necessary

operating settings, all alternate profiles, and parameters

prior to operation with an energized recloser.

ote:N Initial programming of the control is the responsibility

of a qualified technician or engineer familiar with

control functions and programming parameters

required for the specific recloser installation.

The control must be programmed with the Form 6 ProView

interface software. Refer to Service Information S280-70-4

(ProView 4.X.X) or S280-70-21 (ProView 5.X.X) Form 6

Control Programming Guide for additional information.

Control/recloser compatibility

The Form 6 rack mount recloser control is adaptable to the

following Eaton Cooper Power series reclosers:

WE*, WVE27, WVE38X, VWE, VWVE27, VWVE38X,

VSA12, VSA16, VSA20, VSA12B, VSA20A, VSO12, VSO16,

Auxiliary-Powered NOVA reclosers.

* This control is not compatible with Form 1 Type WE

reclosers below s/n 300 and RE reclosers below s/n 400.

IMPORTANT

All Auxiliary-Powered NOVA reclosers require power at the

input power receptacle for tripping and closing.

A new control cable is required to connect the Form 6 rack

mount recloser control to these reclosers. Refer to Table3

in the Recloser connections/control cable Section of the

Customer connections for DC power and AC voltage

sensing section of this manual.

Loading...

Loading...