Do you have a question about the ebm-papst R3G630-FA38-03 and is the answer not in the manual?

Explains hazard level symbols (DANGER, WARNING, CAUTION, NOTE) and their meanings.

Specifies requirements for personnel handling the device.

General safety guidelines and workplace cleanliness.

Mentions voltage considerations.

Discusses the importance of guards and protective devices.

Addresses potential interference and shielding measures.

Warns about hazards related to rotating parts.

Notes potential noise levels and hearing protection.

Warns about burn risks from hot surfaces.

Provides guidance on safe handling and transport.

Details proper storage conditions to maintain device integrity.

Lists prohibited operations that could be hazardous.

Shows dimensional drawings and reference points for the device.

Presents key specifications and ratings of the device.

Provides energy efficiency data as per EU regulation.

Details the technical specifications and features of the device.

Specifies requirements for secure mounting.

Outlines conditions for safe transport and storage.

Details EMC immunity and emission standards.

Provides instructions for physically connecting the device.

Details the process and safety precautions for electrical hookup.

Specifies fuse assignments and cable cross-sections.

Explains reactive currents due to EMC filter.

Recommends specific RCCB types for safety.

Discusses potential increase in leakage current.

Details protection against locked rotor conditions.

Guides on preparing and connecting cables within the terminal box.

Provides instructions for routing cables to prevent moisture ingress.

Lists the default configuration settings for the device.

Illustrates the wiring of terminals and connections.

Details various parameter and input/output configuration options.

Shows electrical schematics for various inputs and outputs.

Provides steps to verify secure and proper connections.

Instructions for safe startup and initial operation.

Procedures for safely turning off the device.

Describes integrated protective functions and their responses to faults.

Addresses issues related to temperature and operating conditions.

Explains LED indicators and their corresponding error codes.

Details LED status codes for various fault conditions.

Provides guidelines for checking mechanical vibration.

Instructions for cleaning the device to ensure longevity.

Guidance on performing high-voltage tests with DC voltage.

Lists items to check, how to check, frequency, and action.

Highlights country-specific regulations for product disposal.

Provides guidelines for separating and recycling device components.

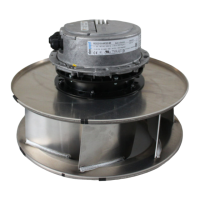

This document describes the R3G630-FA38-03 fan, a built-in device designed for conveying air. It is intended for use in stationary systems within specific environmental and electrical parameters, and adherence to all safety regulations and operating instructions is crucial for proper function and longevity.

The R3G630-FA38-03 is an axial fan, specifically a M3G150-FF motor-impeller combination, designed for air conveyance. It operates on a 3-phase AC power supply with a nominal voltage range of 380-480 VAC and a frequency of 50/60 Hz. The fan features a die-cast aluminum electronics housing and a PP plastic impeller with 6 blades, rotating clockwise when viewed toward the rotor. It incorporates an integrated PI controller, motor current limitation, soft start, and thermal overload protection for both electronics and motor. The device also includes line undervoltage and phase failure detection.

The fan's control interface offers configurable inputs/outputs (I/O) and supports MODBUS V6.0 via an RS-485 MODBUS-RTU interface, allowing for external parameterization. It can be controlled via analog input (0-10V/PWM) for speed set value, and provides a voltage output (3.3-24 VDC) for external devices. Status and alarm indications are provided by an LED and an alarm relay. The device is designed for continuous operation within specified ambient temperature ranges, with occasional start-up permitted at lower temperatures.

The R3G630-FA38-03 is designed for use in power systems with grounded neutral (TN/TT), phase conductor grounding, or IT power systems, adhering to EN 50160 network quality characteristics. It must be used in stationary systems and is not suitable for conveying solids, abrasive particles, highly corrosive air (unless specifically protected), or air with high dust content. Operation near flammable materials or in explosive atmospheres is prohibited.

The device is a built-in component and requires proper safeguarding with a fixed protective device and guard grill. It is crucial to ensure that the device is not subjected to force or excessive vibration from the installation. If connected to air ducts, vibration isolation (e.g., compensators) is recommended. The electrical connection requires careful attention to cable selection, routing, and grounding, with specific recommendations for residual current circuit breakers (RCCB) of type B or B+ with a trip threshold of 300 mA and delayed tripping.

The fan offers configurable operational modes, including PWM control, and allows for setting parameters via MODBUS. The factory settings include PWM control, fan/device address 01, max PWM 100%, min PWM 5%, and positive direction of action. The device features integrated protective functions that automatically switch off the motor in case of rotor position detection error, blocked rotor, line undervoltage, or phase failure, with automatic restart capabilities once the fault is cleared.

Regular maintenance is essential for ensuring a long service life and trouble-free operation. This includes:

The device is equipped with maintenance-free ball bearings designed for a service life of 40,000 hours. If bearing replacement is necessary after this period, contact ebm-papst. Modifications, additions, or conversions to the device without ebm-papst's approval are prohibited. Loose connections and defective cables must be replaced immediately. Disposal of the product and its components must follow country-specific legal requirements and standard procedures for electronic scrap, steel, copper, aluminum, and plastic.

Loading...

Loading...