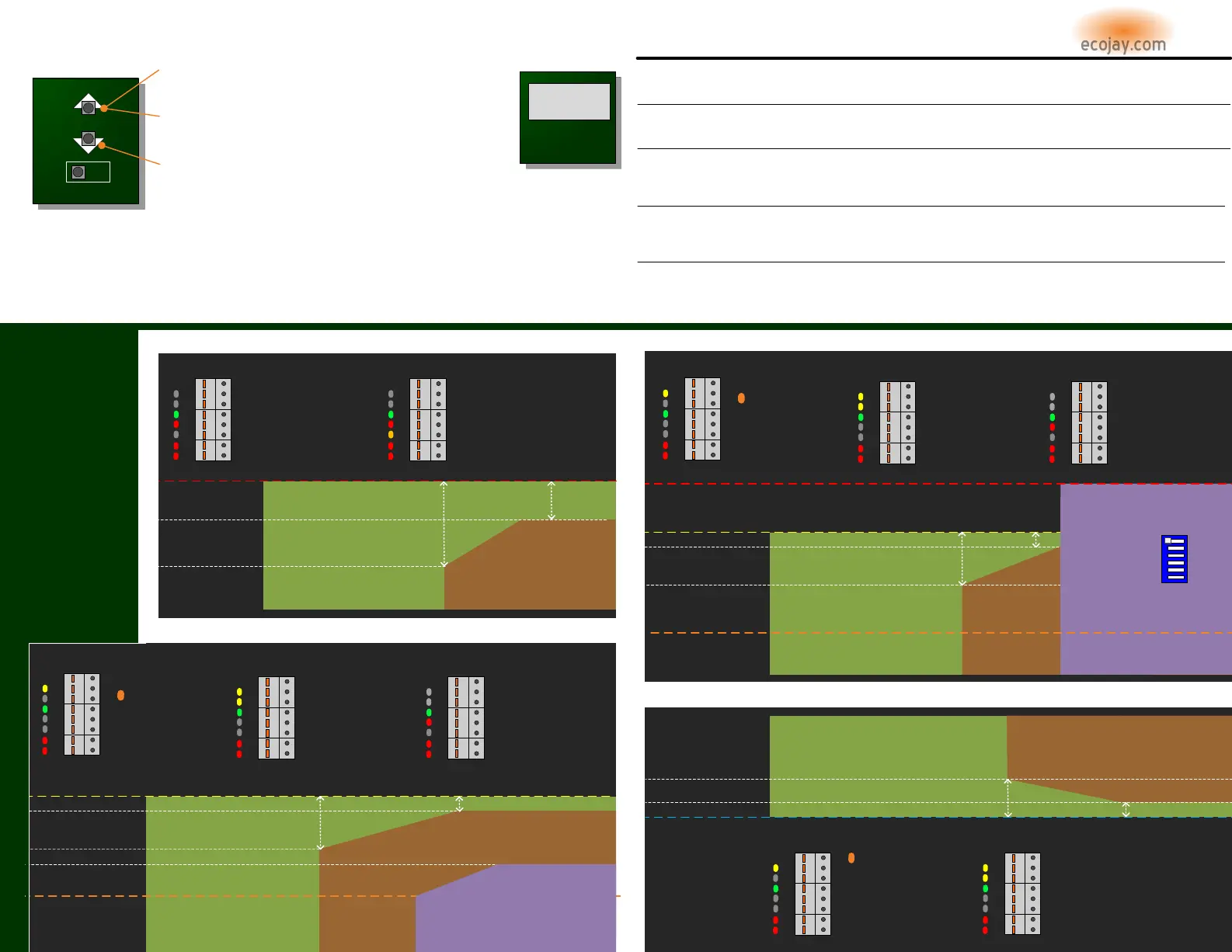

SmartZone EQUIPMENT STAGING

1ST STAGE

-10⁰

-25⁰

HI TEMP CUT-OUT

2

nd

STAGE CUT-IN

2

nd

STAGE CUT-IN

(3-Minute

Minimum Run

Time)

(Starts when first call

for heat is made)

GAS/ELECTRIC HEATING

135⁰

110⁰

125⁰

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

2ND STAGE

12

8

4

0

TIME (Minutes)

Adjustable Range:

(125 to 150°F)

1ST STAGE

-15⁰

HI TEMP CUT-OUT

2

nd

STAGE CUT-OUT

2

nd

STAGE CUT-IN

AUX. HEAT CUT-IN

(Starts when first call

for heat is made)

HEAT PUMP (NORMAL) – HEATING [ELECTRIC AUX.]

115⁰

120⁰

90⁰

105⁰

100⁰

AUX. HEAT CUT-OUT

0

2

4

TIME (Minutes)

Adjustable Range: (110 to 125°F)

►W1 de-energizes at a supply air

temp warmer than HI temp cut-out

and will re-energize after 3 min if

supply temp has fallen lower (cooler)

than HI temp (Default: 135°F)

►W2 energizes at a supply air temp

cooler than 25⁰ less than HI temp cut-

out after 8 minutes run time of W1 only.

(Default: 135 - 25 = 110 or cooler)

►W2 de-energizes at supply air

temp warmer than 10⁰ less than HI

temp cut-out after 3 min of minimum

run time.

(Default: 135 - 10 = 125 or warmer)

The SmartZone controls equipment

staging automatically based on

time and supply air temperature.

(This temperature is read by the

SUPPLY AIR TEMP SENSOR – SEE

previous page for proper

installation) NOTE:

Without this

sensor installed, the SmartZone will

NOT run 2

nd

stage or operate any

dampers.

The charts in this section illustrate

this correlation between TIME,

TEMPERATURE, & STAGING

(

FACTORY DEFAULTS SHOWN IN

CHARTS

)

Time and temperature settings will

vary according to the type of

equipment SmartZone is configured

for and the HI/LO temp limit

settings used. Staging will occur

ONLY when the minimum run-time

and temperature range conditions

are met. The factory default

settings for temperature cut-in and

cut-out are adjustable. (SEE HIGH

and LOW LIMIT ADJUST section

above)

1

ST

STAGE

2

nd

STAGE

SUPPLY AIR TEMP (⁰F) DEFAULT Values

SUPPLY AIR TEMP (⁰F) DEFAULT Values

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

►Y2 energizes at a supply

temp 15⁰ less than HI temp

cut-out (or cooler) after a 4

minute run time of Y1 only.

(Default: 120⁰ - 15⁰ = 105⁰F

or cooler Y2 energizes)

►Y2 de-energizes at a supply

temp of 5⁰ less than HI temp

cut-out (or warmer) after 3 min

of minimum run time.

(Default: 120⁰ - 5⁰ = 115⁰F or

above Y2 de-energizes)

2

nd

STAGE

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

1

ST

STAGE

►Y1 and G equipment

terminals energize when any

thermostat calls for heat.

NOTE: B will also energize

if DIP SWITCH #2 set to B

►Y1 de-energizes at a supply

temp warmer than (above) HI

temp cut-out and will re-

energize after 3 min if supply

temp has fallen lower (cooler)

than HI temp (Default: 120⁰F)

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

AUX. HEAT

►W1 [Auxiliary Heat]

energizes while Y1&Y2

de-energize at a supply

temp cooler than 90⁰F

after 6 minutes run time

of Y1 & Y2 only.

►W1 [Auxiliary Heat]

de-energizes at a

supply temp of 100⁰F

or warmer (NON-

ADJUSTABLE)

►W1 & G energize when any

thermostat calls for heat.

G will energize immediately if DIP

SWITCH #5 is set to “ELECTRIC”.

If set to the default of “GAS”, G will

energize after 90 seconds.

*

Adjustable Range:

(90 to 94°F)

2ND STAGE

(3-Minute Minimum

Run Time)

-5⁰

6

AUX HEAT

8

HIGH AND LOW LIMIT ADJUST

5

1ST STAGE 2ND STAGE

-15⁰

-5⁰

HI TEMP CUT-OUT

2

nd

STAGE CUT-OUT

2

nd

STAGE CUT-IN

(3-Minute Minimum

Run Time)

(Starts when first call

for heat is made)

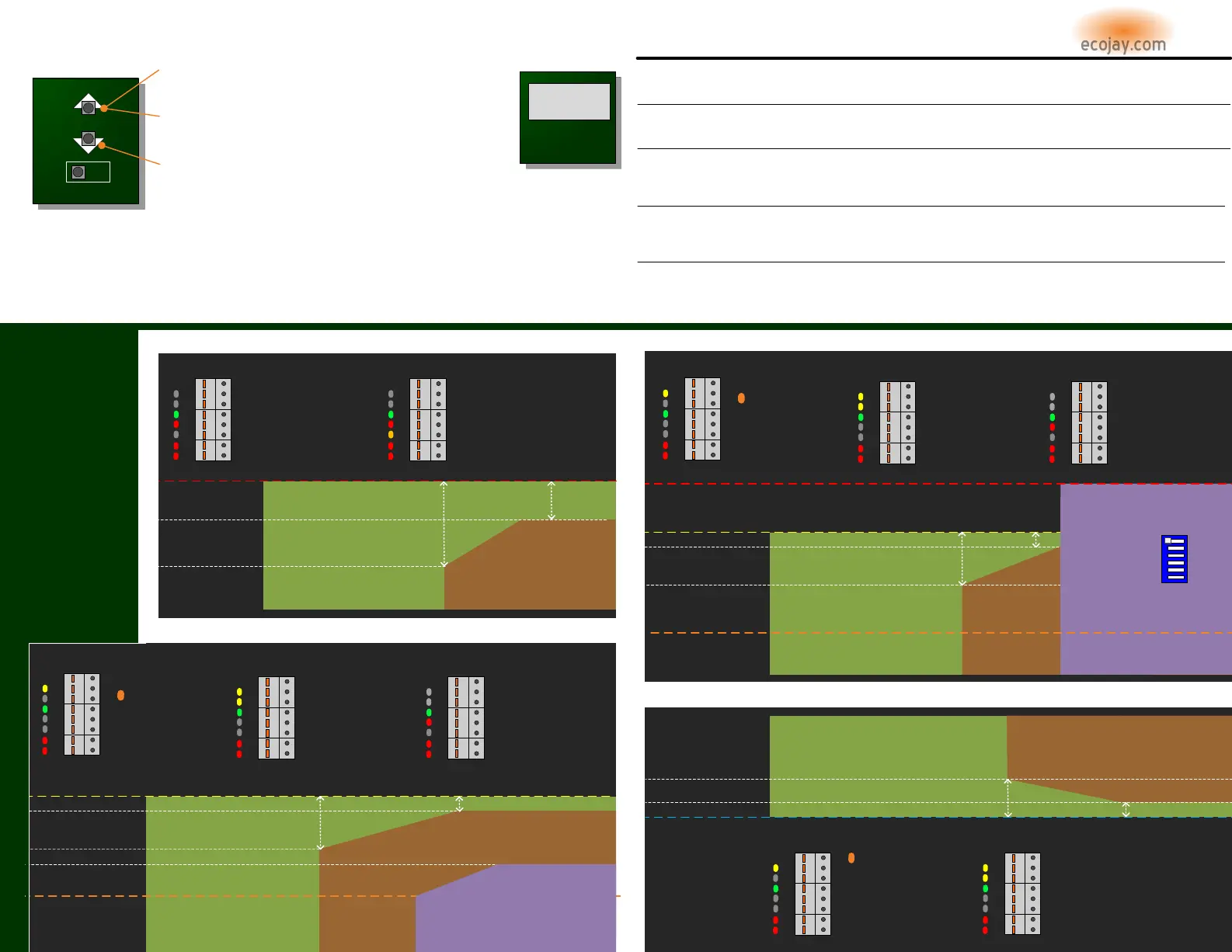

HEAT PUMP (DUAL FUEL) – HEATING [GAS AUX.]

115⁰

120⁰

105⁰

AUX. HEAT

(Once AUX Heat has started

in Dual Fuel mode, it will

continue to run until all heat

calls are satisfied.)

135⁰

GAS AUX. HEAT HI TEMP CUT-OUT

0

2 4

6

8

TIME (Minutes)

1ST STAGE

+10⁰

LOW TEMP CUT-OUT

2

nd

STAGE CUT-IN

2

nd

STAGE CUT-OUT

(3-Minute Minimum

Run Time)

(Starts when first call

for cool is made)

COOLING ALL

58⁰

48⁰

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

►Y1 de-energizes at a supply air

temp lower (cooler) than the LO

temp cut-out and will re-energize

after 3 min if supply temp has risen

above (warmer) than LO temp.

(Default: 48°F or cooler)

►Y1 and G energize when any

thermostat calls for cool.

►Y2 energizes at a supply air temp

higher (warmer) than 10⁰ more than

LO temp cut-out after 8 minutes run

time of Y1 only.

(Default: 48⁰ + 10⁰ = 58⁰F or warmer)

►Y2 de-energizes at a supply air temp

cooler than 4⁰ more than LO temp cut-out

after 3 min of minimum run time.

(Default: 48⁰ + 4⁰ = 52⁰F or cooler Y2 de-

energizes)

2ND STAGE

128

4

0

TIME (Minutes)

(NOTE: O will also energize if

DIP SWITCH

# 1 set to HEAT PUMP and

#2 set to O)

+4⁰

52⁰

Adjustable Range: (41 to 55°F)

Adjustable Range: (110 to 125°F)

**

AUTO CHANGEOVER

ADJUST SETTINGS

STAT

TYPE

PRESS & release the ▲ ”UP” arrow button when the display is showing SUPPLY temperature. The “HI

TEMP” indicator will flash and the digits will show the currently set temperature. This high limit cut-out

can be adjusted up or down using the ▲▼buttons. See EQUIPMENT STAGING below for more details.

PRESS & release the ▼ ”DOWN” arrow button when the display is showing SUPPLY temperature. The “LO

TEMP” indicator will flash and the digits will show the currently set temperature. This low limit cut-out can

be adjusted up or down using the ▲▼buttons. See EQUIPMENT STAGING below for more details.

SET HIGH TEMP LIMIT (CUT-OUT)

SET LOW TEMP LIMIT (CUT-OUT)

IMPORTANT NOTE:

Changing either the LOW or HIGH temp limit will also affect the staging

cut-in and cut-out temperatures settings. Adjusting these can cause staging to occur sooner or

later as needed. See EQUIPMENT STAGING below for more details about each scenario.

PRESS & HOLD the ▲ ”UP” arrow button for 5 seconds when the display is showing SUPPLY

temperature. When released the “HI LIMIT” and “DELAY” indicators will flash and the digits will

show the currently set temperature (DEFAULT = 90, adjustable from 90 to 94 using ▲▼buttons).

AUX. HEAT CUT-IN

See EQUIPMENT STAGING below for more details. For protection, SmartZone will not allow the EQUIPMENT to run above or below these settable limits.

With the SmartZone system, it is possible to have a zone(s) calling for cool and another zone(s) calling for heat. These are called opposing calls. When the

equipment has an active call running and SmartZone receives an 'opposing call' from another zone(s), the existing active mode running on the equipment will be

limited to a maximum run time of 15 minutes from the time the first opposing mode call was received. If the active mode does not satisfy the calling zone(s) in this

15 minute interval SmartZone will initiate a CHANGEOVER process de-energizing the active mode and initiating a 3 minute PURGE (see page 3 for more about

PURGE). During PURGE, all dampers open during the previously active mode remain open and the fan remains energized to neutralize the supply air temperature

before energizing the opposing call mode on the equipment CHANGEOVER process.

NOTE: SET DIP SWITCH #3

to GAS/ELECT temporarily to

adjust this HI LIMIT CUT-

OUT. Make sure to set it

back to HEAT PUMP when

adjustment is complete.

**

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

►Y2 energizes at a supply

temp 15⁰ less than HI temp

cut-out (or cooler) after a 4

minute run time of Y1 only.

(Default: 120⁰ - 15⁰ = 105⁰F

or cooler Y2 energizes)

►Y2 de-energizes at a supply

temp of 5⁰ less than HI temp

cut-out (or warmer) after 3 min

of minimum run time.

(Default: 120⁰ - 5⁰ = 115⁰F or

above Y2 de-energizes)

2

nd

STAGE

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

1

ST

STAGE

►Y1 and G equipment

terminals energize when any

thermostat calls for heat.

NOTE: B will also energize

if DIP SWITCH #2 set to B

►Y1 de-energizes at a supply

temp warmer than (above) HI

temp cut-out and will re-

energize after 3 min if supply

temp has fallen lower (cooler)

than HI temp (Default: 120⁰F)

RC

RH

COM

W2

O/B

Y1

Y2

G

EQUIPMENT

W1

EH

AUX. HEAT

►W1 [Auxiliary Heat]

energizes AND Y1 & Y2

will de-energize at a

supply temp cooler than

90⁰F after 6 minutes run

time of Y1 & Y2.

►W1 [Auxiliary Heat]

remains energized until all

heat calls are satisfied or the

supply temp gets warmer

than “GAS/ELECTRIC” HI

limit (Default: 135⁰F)

AUX. HEAT CUT-IN

90⁰

SUPPLY AIR TEMP (⁰F) DEFAULT Values

1

ST

STAGE

SUPPLY AIR TEMP (⁰F) DEFAULT Values

2

nd

STAGE

Adjustable Range:

(90 to 94°F)

Adjustable Range: (125 to 150°F)

HEAT PUMP

B

DUAL FUEL

ELECTRIC

GAS/ELECT

RVS. VLV. O

NORMAL

FAN GAS

LOCKOUT2

nd

STAGE

SMART LINK

ZONES (1 – 4)

ZONES (5 – 8)

SE

HI TEMP

LO TEMP

SUPPLY

PURGEDELAY ECO

TO SAVE SETTINGS,

wait for display to

show “St” (STORE)

4

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

DISPLAY IS BLANK

►VERIFY OUTPUT OF TRANSFORMER INCLUDING CONNECTIONS TO PRIMARY, SECONDARY AND ZONE PANEL POWER CONNECTOR

►CHECK TRANSFORMER FUSE

►CHECK SMARTZONE FUSE (SPARE INCLUDED)

►CHECK FOR SHORT IN WIRING CONNECTED TO SMARTZONE (REMOVE THERMOSTAT, DAMPER, & EQUIPMENT WIRES)

DISPLAY READS “- - “

►SUPPLY AIR TEMP SENSOR IS NOT CONNECTED TO SMARTZONE

►SUPPLY AIR TEMP SENSOR HAS A LOOSE CONNECTION

►DIP SWITCH # 6 IS SET TO “ZONE 5-8” → THIS IS ONLY FOR 8 ZONE APPLICATIONS

►SUPPLY AIR TEMP SENSOR IS DEFECTIVE

THERMOSTAT INDICATES CALL BUT

EQUIPMENT TERMINALS NOT RESPONDING

►SMARTZONE IS IN “DELAY” OR “PURGE” - DISPLAY SHOULD BE COUNTING DOWN IN SECONDS TIME REMAINING (3 MIN)

►AN INCOMPATIBLE THERMOSTAT IS CONNECTED TO SMARTZONE (THERMOSTATS WITH A COMMON SHOULD BE USED)

►WIRING BETWEEN SMARTZONE AND EQUIPMENT COULD BE DAMAGED OR NOT SECURELY CONNECTED

►TRANSFORMER TO POWER SMARTZONE & COMPONENTS COULD HAVE INNSUFFICIENT VA RATING

►PRIMARY POWERING SMARTZONE TRANSFORMER COULD BE BEYOND CAPACITY (USE DEDICATED CIRCUIT FROM BREAKER)

SMARTZONE EQUIPMENT INDICATES HEAT/COOL

CALL BUT EQUIPMENT NOT ENERGIZING

►RC/RH JUMPER MISSING OR INSTALLED ON ONLY ONE PIN

►EQUIPMENT TRANSFORMER NOT CONNECTED, SHORTED OR LOOSE CONNECTION (ALSO CHECK FUSE)

►SMARTZONE TRANSFORMER INSUFFICIENT VA (SEE PAGE 2)

►ECO MODE ENERGIZED: “ECO” WILL BE ILLUMINATED ON DISPLAY (SEE PAGE 2)

►SMARTZONE HAS DEFECTIVE EQUIPMENT RELAY (CALL FOR RMA VERIFICATION)

HEAT PUMP ONLY: SMARTZONE ENERGIZES

COOLING WHEN ZONES CALL FOR HEAT

(O/B DOESN‟T ENERGIZE)

►”STAT TYPE” SETTING DOES NOT MATCH THERMOSTAT BEING USED (PRESS STAT TYPE BUTTON – PAGE 6)

►AN INCOMPATIBLE THERMOSTAT IS CONNECTED TO SMARTZONE (THERMOSTATS WITH A COMMON SHOULD BE USED)

►DIP SWITCH # 2 (REVERSING VALVE) SET TO OPPOSITE MODE “O” OR “B”

►WIRING BETWEEN SMARTZONE O/B TERMINAL AND EQUIPMENT COULD BE DAMAGED OR NOT SECURELY CONNECTED (CHECK VOLTAGE)

MORE INFO ON

TROUBLESHOOTING

ecojay.com

ecojay.com

Loading...

Loading...