IV.

EARTH LOOP

WATER

PIPING

Since water is the

source of energy

in

the

wintertime

and

the

energy sink

in

the summertime,

good

water supply is

possibly

the most important requirement of a

geothermal

heat

pump

system installation. There are two common

types of water supplies,

closed

loop

systems

and

open

loop systems.

A.

Closed

Loop Applications

A closed loop

system

recirculates

the

same

water/antifreeze solution through a closed system of

underground high-density

polyethylene

pipe.

As the

solution

passes

through the

pipe,

it collects heat

(in

the

heathg mode)

that is being transferred

from

the

relatively

warm

surrounding soil through the

pipe

and into the

relatively cold solution. The solution is circulated to the

heat

pump,

which

pulls

heat out of the solution, and

then

back through the

ground

to extract more heat

from

the

earth.

The GeoSource 2000 is

designed

to operate on either

vertical

or

horizontal

closed

loop

applications.

Vertical

loops

are typically installed with a

well

drilling

rig up to

200 feet

deep or

more. Horizontal

systems

are typically

installed with excavating or trenching equipment

approximately

six to

eight

feet deep, depending on

geographic

location

and length ofpipe used.

Earth loops

must be

sized

properly

for

each

particular geographic

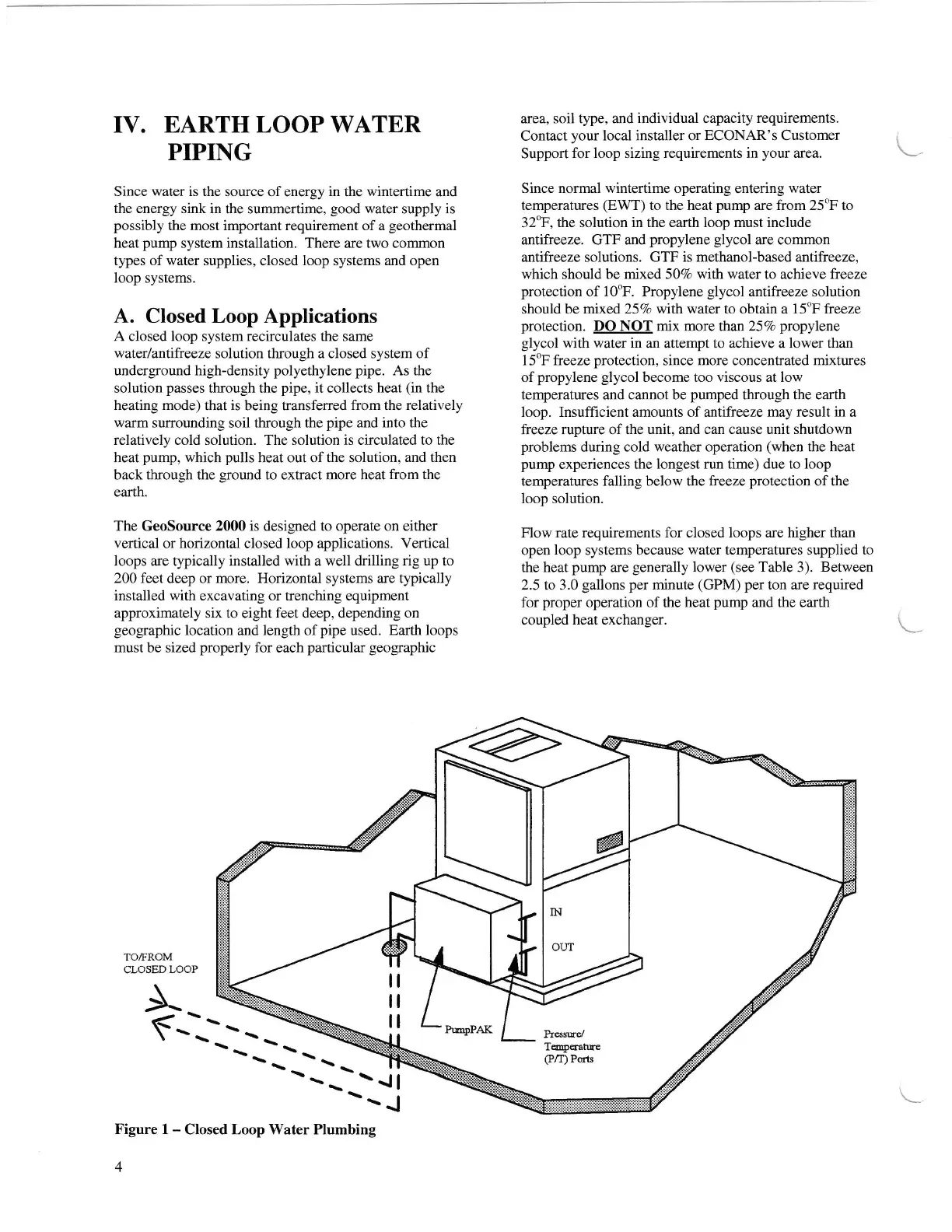

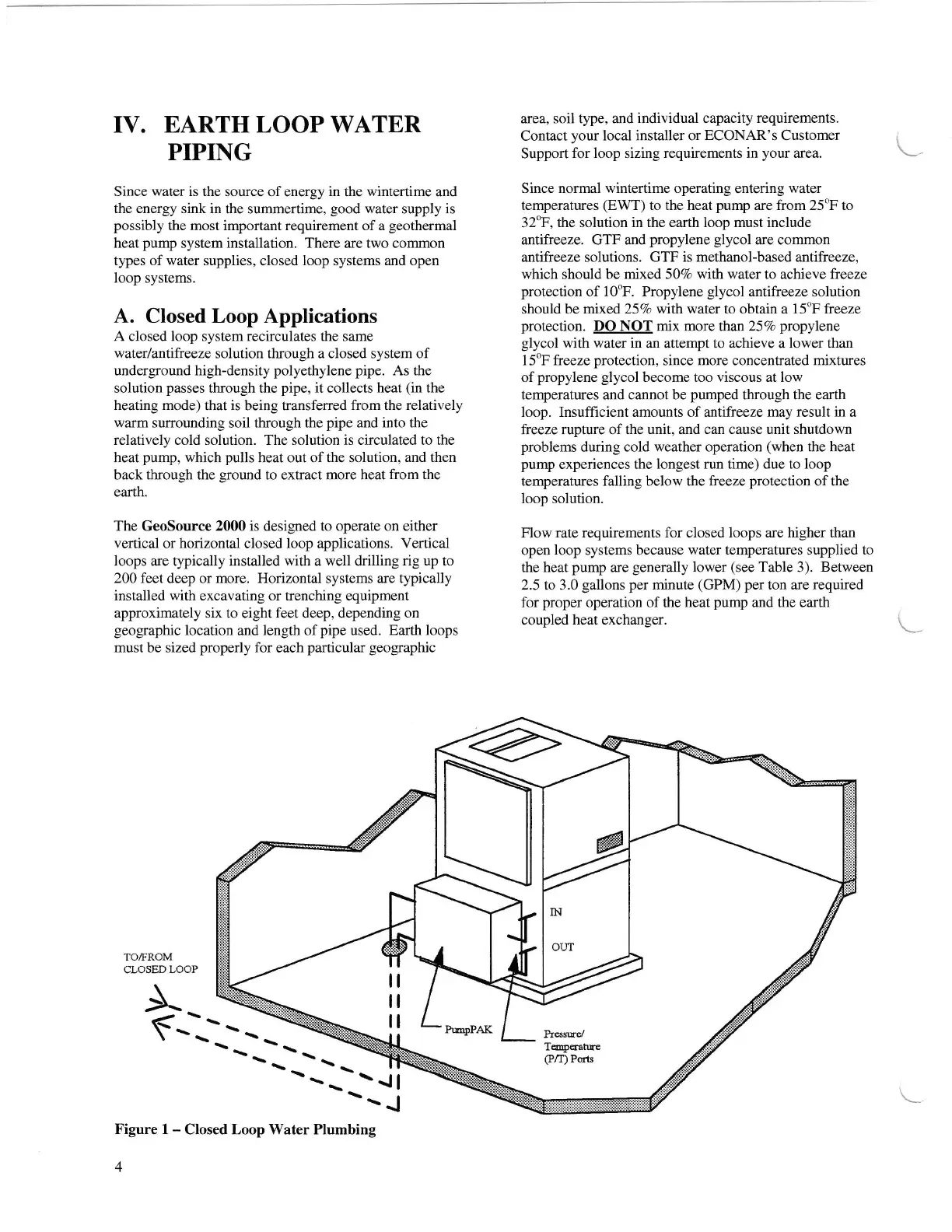

TO/FROM

CLOSED LOOP

area,

soil type, and

individual capacity requirements.

Contact

your

local installer or

ECONAR's

Customer

Support

for loop sizing requirements in

your

area.

Since

normal whtertime

operating entering

water

temperatures

@Ury)

to the heat

pump

are from 25oF to

32oF, the solution

in the

earth

loop must include

antifreeze. GTF and

propylene glycol

are common

antifreeze solutions.

GTF is methanol-based antTfreeze,

which

should

be mixed 50Vo with water to achieve freeze

protection

of 10oF. Propylene

glycol

antifreeze

solution

should be

mrxed25Vo with water to obtain

a

15oF freeze

protection.

DO NOT mix more than25%o

propylene

glycol

with water

in

an attempt to achieve a

lower

than

15T freeze

protection,

since more concentrated mixtures

ofpropylene

glycol

become too viscous at low

temperatures and cannot be

pumped

through the earth

loop. Insufficient amounts of antifreeze may result

in

a

freeze rupture of the unit, and can

cause unit shutdown

problems

during cold

weather operation

(when

the heat

pump

experiences the

longest run time) due

to

loop

temperatures falling below the freeze

protection

of the

loop solution.

Flow

rate requirements for closed loops are higher than

open loop systems because

water temperatures supplied to

the

heat

pump

are

generally

lower

(see

Table

3).

Between

2.5

to 3.0

gallons per

minute

(GPM) per

ton are

required

for

proper

operation of the heat

pump

and the earth

coupled

heat exchanger.

\

f

\

Figure 1-

Closed Loop Water Plumbing

4

.Jl

IN

OUT

PmPPAK

Presre'/

Tmposhre

(P/T)

Pofis

J

il

il

il

Loading...

Loading...