34

MONITORING – ILD-X & SGA-1

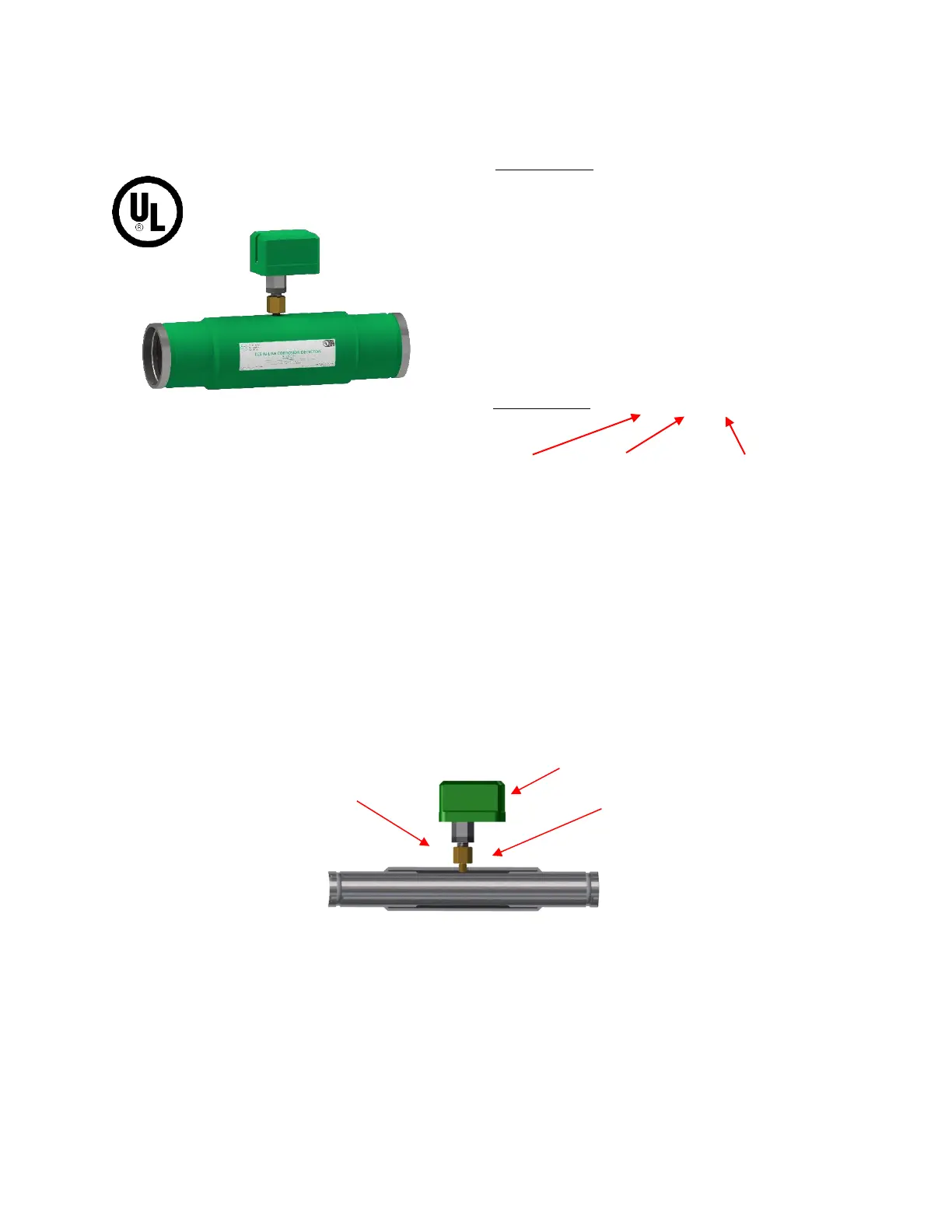

ECS In-Line Corrosion Detector (ILD-X)

General Description

The ECS In-Line Corrosion Detector is designed to provide an early warning indication of internal corrosion

activity in water-based fire sprinkler systems. The device is designed to be installed where corrosion is

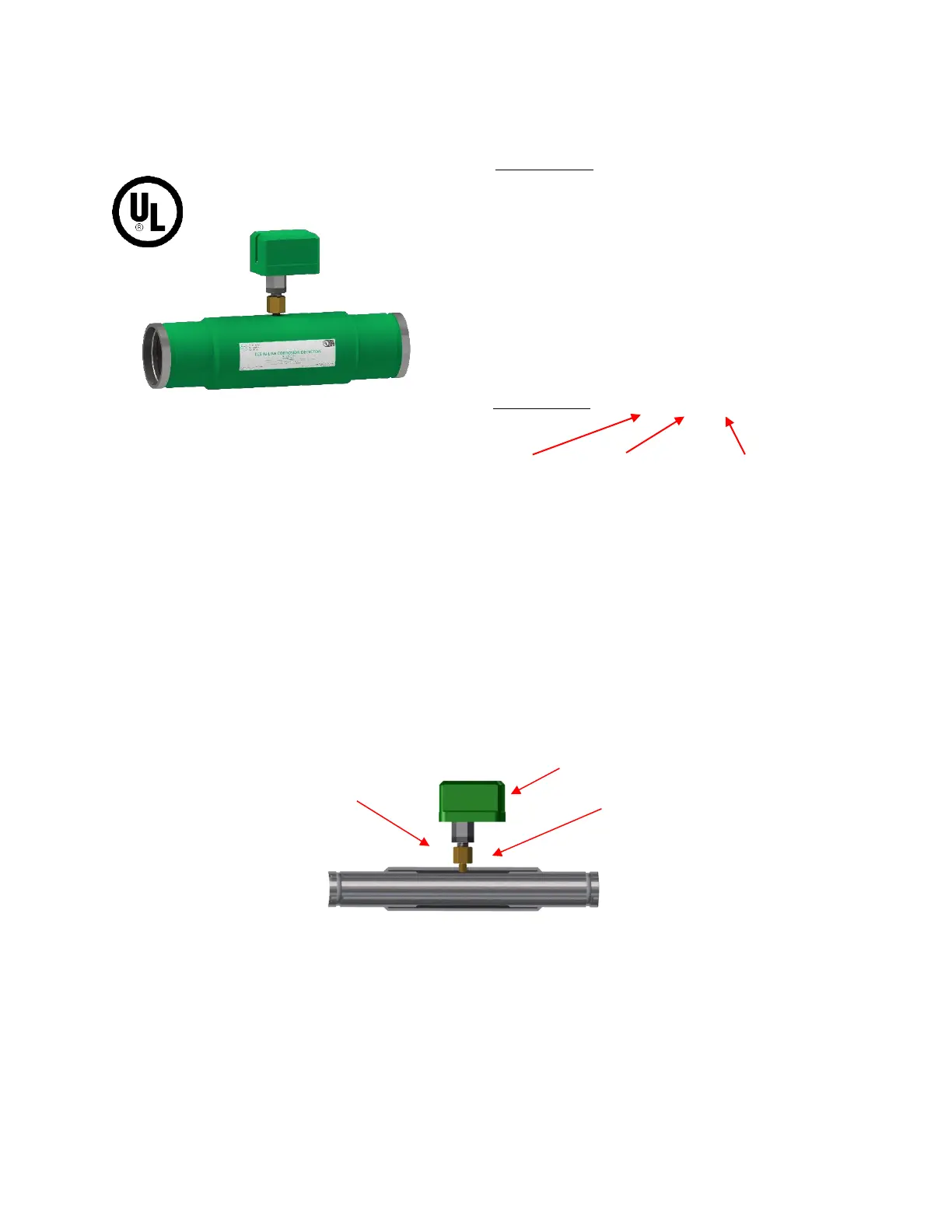

most likely to occur: the air/water interface. A cross-section of the device shows the two key attributes

that allow for early detection of corrosion: an externally milled section of the pipe that creates a

“thin wall” section and a pressure chamber created by an external sleeve welded over the pipe. The thin

wall section of the device will fail before other system piping to provide an early warning indication. The

In-Line Corrosion Detector is equipped with a pressure switch to monitor the pressure chamber. The

In-Line Corrosion Detector can be remotely monitored through a buildings monitoring system.

Installation Instructions

The In-Line Corrosion Detector is manufactured as a spool of piping with roll grooved ends for easy

insertion into the fire sprinkler piping using standard mechanical couplings (supplied by others). All

models of the In-Line Corrosion Detectors are eighteen (18) inches in length. The variety of pipe schedules

and metal are listed in the table under ordering information.

Specifications

Stock Number: ILD-X

Service Pressure: 175 psi

Temp. Rating: -40°F to 120°F (-40°C to 49°C)

Elec. Connection: dry contact

Pipe Size: 1.25” - 6”

Pipe Schedule: Sch. 10 or Sch. 40

Pipe Material: Black Steel or Galvanized

Loading...

Loading...