• Hold the meter steady and at against

the test surface during measurement

• Do not touch the glass with your hand

while taking the reading

• Take readings at the bottom center of

the window for best thickness accuracy

(see explanation below)

• Take multiple readings to verify results

• Make sure the window being measured

is clean

• Make sure the two lenses on the back of

the GC3000 are clean. Use only clean,

compressed air to clean the lenses. Only

use a lint free cloth if absolutely neces-

sary to clean smudges, ngerprints, etc.

•

Make sure nothing is touching the far side

surface of the window during the reading

• It is best to test windows in free air (not

resting on a tabletop surface).

Recommended placement of meter:

•

Hold the meter steady AND FLAT against

the glass during measurement.

• The meter should be centered on one of

the four edges of the window with the bot-

tom edge of the meter placed parallel to

the edge of the window (please see the

image to the left). This will minimize the

effect of a concave window. As you move

away from the edge of a window, many

windows will bow inward (concave). Be-

cause the sensor runs parallel to the bot-

tom edge of the meter, it is important to

place the bottom edge of the meter along

the edge of the window as shown.

•

DO NOT touch the glass with your hand

while taking readings. Note the hand

placement used in the picture at left. The

user’s thumb is resting on the GC3000

without touching the glass being mea-

sured. Also, be sure there are no other

metallic objects touching the glass

• DO NOT hold down the button while tak-

ing a reading.

•

Place your index nger next to the button.

Incorrect placement for accurate results:

• DO NOT hold the button down while

taking a measurement. This will cause

the meter to turn off. Rest your index

nger next to the button as shown.

• DO NOT touch the glass with your hand

while taking readings. This could cause

incorrect results for the Low-E measure-

ment.

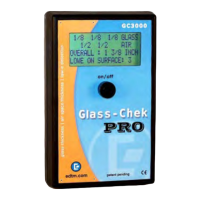

EXPLANATION OF MEASUREMENT DISPLAYS

The Glass-Chek Pro offers various display formats. The following illustrations are ex-

amples of measurement displays with explanations of the application being tested and

how the display format was congured.

— Measurement Display Example One —

Display Format

• Dimensions: Inch

• Standard: Fraction

• Actual: Decimal

Application

• Double pane

window

• Soft Coat Low-E

on surface 2

— Measurement Display Example Two —

Display Format

• Dimensions: MM

• Standard: ON

• Actual: OFF

Application

• Double pane

window

• Hard Coat Low-E

on surface 3

— Measurement Display Example Three —

Display Format

• Dimensions: Inch

• Standard: Fraction

• Actual: Decimal

Application

• Triple pane

window

• Low-E on

surface 5

— Measurement Display Example Four —

Display Format

• Dimensions: MM

• Standard: OFF

• Actual: ON

Application

• Double pane

window

• No Low-E coating

• Suspended Film

between panes

Figure 2: Back of GC3000 meter with the two lenses

circled. Use clean compressed air to clean the lenses.

GUIDELINES FOR MOST ACCURATE RESULTS:

4 OPTIMAL TEST LOCATIONS FOR MOST ACCURATE RESULTS:

Double Pane

Window

Resulting Measurement Displays: Due to the ap-

plication and display format, the measurement will

alternate the following two messages:

1)

2)

Display 1 shows millimeters rounded to the nearest

standard. Since the “Actual” setting is set to OFF,

there is no display showing the actual dimensions

of the glass - only the dimensions rounded to the

nearest standard. Display 2 shows that the Low-E

coating is on surface 3 or 4. This means that the

meter is only indicating that the coating is on the

second pane of glass. To verify the exact location

of the coating, the user must test the window from

the opposite side. The meter also indicates the coat-

ing

is a hard coat Low-E.

Double Pane

Window

Resulting Measurement Displays: Due to the ap-

plication and display format, the measurement will

alternate the following three messages:

1)

2)

3)

**NOTE** On triple pane measurement displays, “P” =

Glass, and “A” = Air Space.

Display 1 shows fractional inches rounded to the near-

est

standard. Display 2 shows the actual measure-

ments in decimal inches. Notice how the actual mea-

surements

in 2 are slightly different than the mea-

surements in 1 because Display 1 shows the read-

ings rounded to the nearest standard. Display 3

shows that the meter did not detect a Low-E coat-

ing on pane 1 or pane 2. Since the GC3000 only

detects coatings on the rst 2 panes, you may be

required to test both sides of a triple pane window

to verify the presence of Low-E.

Triple Pane Window

Double Pane

with Suspended

Film

IMPORTANT SAFETY CONSIDERATION

The GLASS-CHEK family of glass thickness and air space

meters use a Class 2M laser to take its measurements.

Do NOT push the power button and point the instrument

laser at a persons’ eyes. Always check the other side of

the window being tested to ensure that no one will be

looking directly into the laser.

APPLICATIONS

WILL TEST …

• Flat glass applications

•

Clear glass or glass with Low-E coatings,

self-clean coatings or other specialty

coatings as long as the glass/coating is

transparent

• Laminated glass with Low-E coatings

positioned against the laminate (see

page 4)

• Tinted glass as long as it has a visible

light transmission value of approximate-

ly 35% or above

WON’T TEST …

• Glass coated with reective (mirror-like)

coatings

• Tinted glass with visible light transmis-

sion value at approximately 35% or be-

low

Resulting Measurement Displays: Due to the ap-

plication and display format, the measurement will

alternate the following three messages:

1)

2)

3)

Display 1 shows fractional inches rounded to the

nearest standard. Display 2 shows the actual mea-

surements in decimal inches. Notice how the actu-

al measurements in 2 are slightly different than the

measurements in 1 because Display 1 shows the

readings rounded to the nearest standard. Display

3 shows that the Low-E coating is on surface 2, and

it indicates that the coating properties are soft coat

and have the performance of double-silver Low-E.

Resulting Measurement Displays: Due to the ap-

plication and display format, the measurement will

alternate the following two messages:

1)

2)

Display 1 shows the actual dimensions of the win-

dow in millimeters. Since the “Standard” setting is

set to OFF, the standard dimensions are not dis-

played. The word “FILM” indicates suspended lm

between the two panes of glass. Display 2 indicates

both panes of glass are “CLEAR” of any Low-E

coating, but there is a suspended lm between the

panes.

PANEL 1

PANEL 2

PANE 1

Low-E

AIR SPACE

PANE 2

(

SURFACE 2

PANE 1

PANE 2

PANE 3

SURFACE 3

Low-E

(

SURFACE 5

Low-E

(

AIR SPACE 2

AIR SPACE 1

AIR SPACE

PANE 1

PANE 2

Suspended Film

(

AIR SPACE 2

AIR SPACE 1

2

Loading...

Loading...