en

25

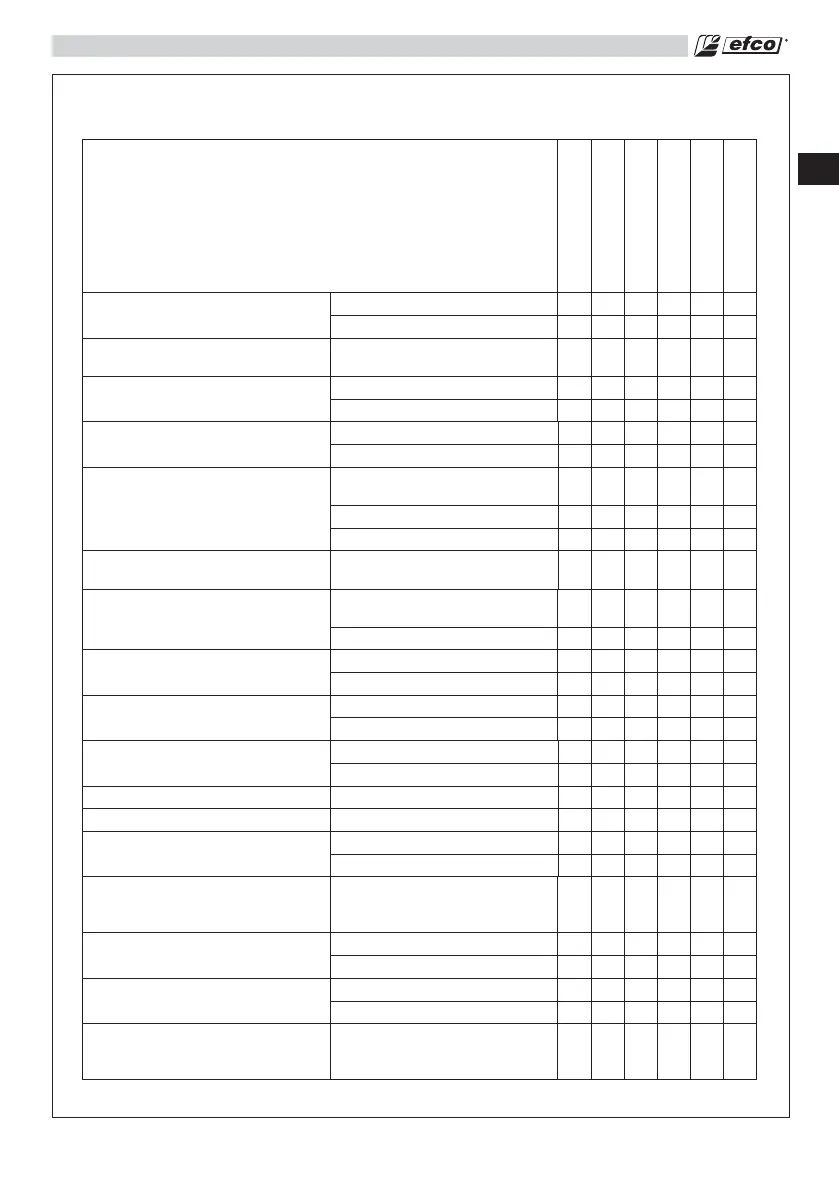

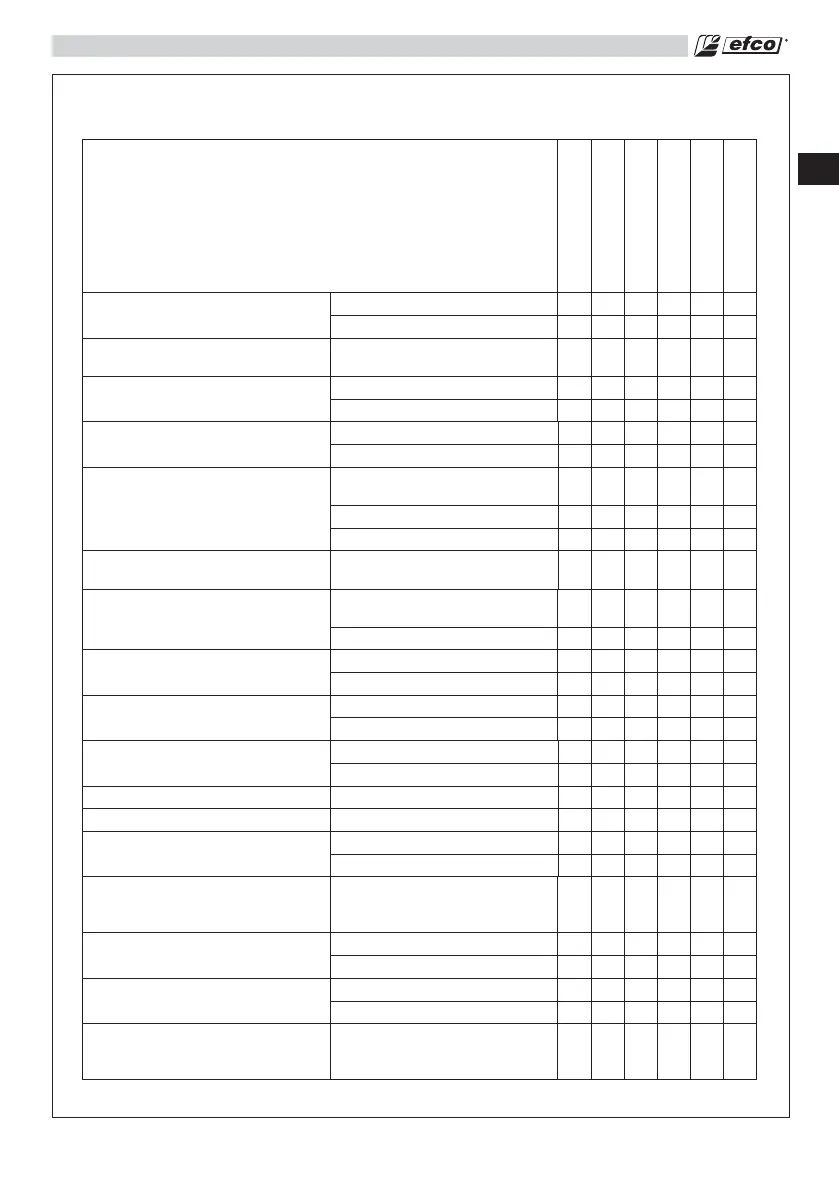

MAINTENANCE

Maintenance Chart

Please note that the following maintenance intervals apply for normal

operating conditions only. If your daily work requires longer than

normal or harsh cutting conditions are present, then the suggested

intervals should be shortened accordingly.

Before Each Use

Monthly

If Damaged or Faulty

As Required

6 mouths or 50 hrs.

1 year or 100 hrs.

Complete Machine Inspect (Leaks, Cracks, and Wear)

x

Clean after finishing daily work

x

Controls (STOP button, Choke Lever,

Throttle Trigger, Trigger interlock)

Check Operation

x

Fuel Tank Inspect (Leaks, Cracks, and Wear)

x

Clean

x

Fuel Filter and tube Inspect

x

Clean, Replace Filter Element

xx

Cutting Attachments Inspect (Damage, Sharpness, and

Wear)

x

Check Tension

x

Sharpen

xx

Bevel Gear Inspect (Damage, Wear and

Grease Level)

xx

Clutch Drum Inspect (Damage, Wear and

Grease Level)

x

Replace

xx

Cutting Attachments Guard Inspect (Damage, and Wear)

x

Replace

xx

All Accessible Screws and Nuts (Not

Adjusting Screws)

Inspect

x

Retighten

x

Air Filter Clean

xx

Replace

xx

Cylinder Fins Clean

x

Starter System Vents Clean after finishing daily work

x

Starter Rope Inspect (Damage, and Wear)

x

Replace

x

Carburetor Check Idle (Cutting Attachments

must not

rotate at idle)

x

Spark Plug Check Electrode Gap

x

Replace

xx

Vibration Mounts Inspect (Damage, and Wear)

x

Replace by Dealer

xx

Cutting Attachments nuts and

screws

Check that the locking nut of the

cutting equipment is tighten

correctly

x

Loading...

Loading...