18

WATER SEPARATION FROM FUEL:

The air moisture trapped inside the fuel tank gets condensed during night time, becomes water and mixes

with diesel. If this water is allowed to flow through the fuel system it can damage the FIP and nozzle.

Since the engines are used for power generation application which is operated under stationery condition,

the fuel tank acts as water separator. The foreign particles in fuel are collected as sediments in fuel tank

bottom and water in fuel are collected at the bottom of the fuel tank. Ensure periodical draining of water

from fuel tank through the drain plug provided in the fuel tank.

Ensure periodical cleaning of Fuel tank to make it free from Sediments.

Do not top up fuel in fuel tank when the engine is under operation as the process will allow sediments and

water to float and gets carried away along with fuel. Always top up fuel in fuel tank when the engine is not in

operation. Wait for few minutes and allow sometime for sediments and water to settle at the bottom of the

fuel tank before starting the engine.

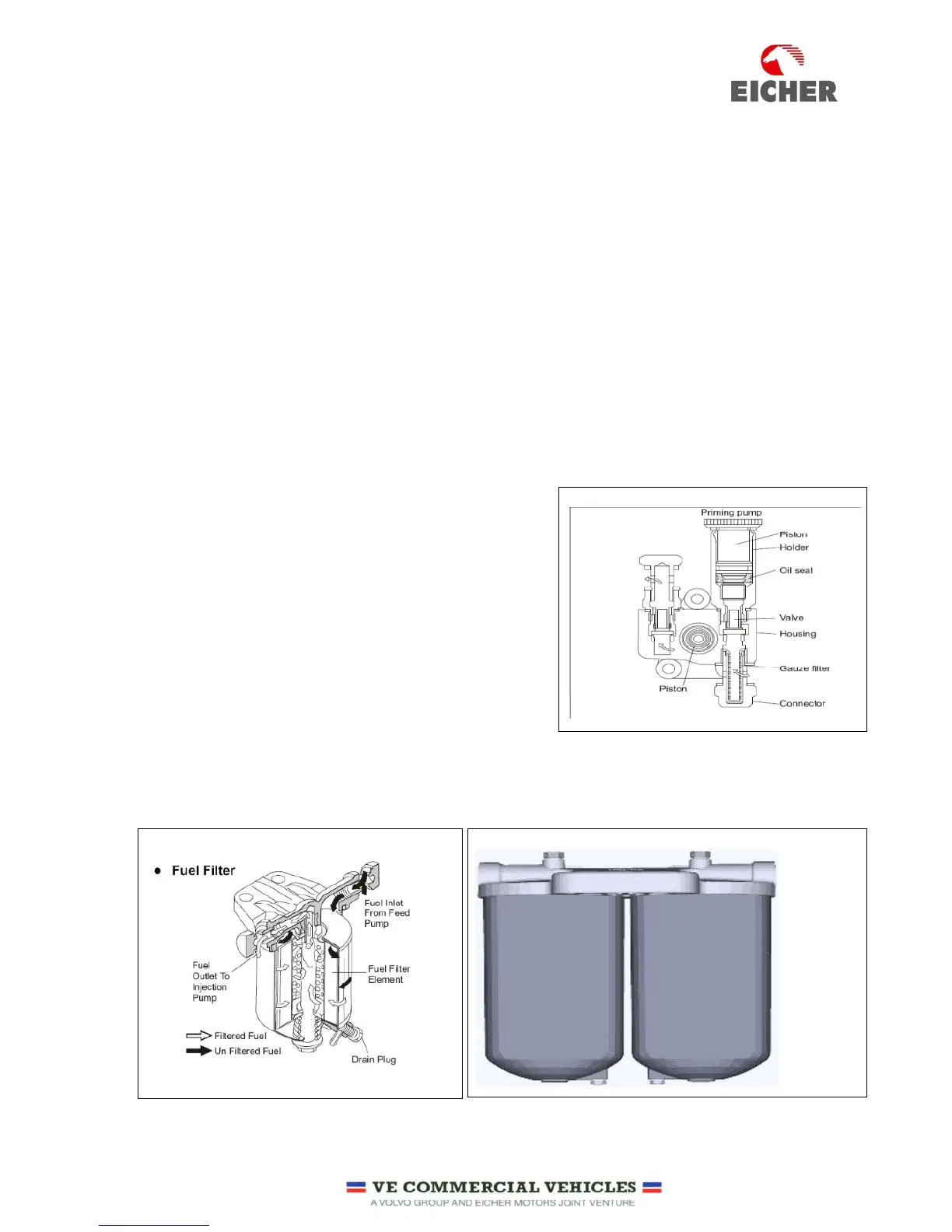

FEED PUMP:

The feed pump is driven by the Fuel injection pump

camshaft.

The priming pump allows manual lift of fuel when the

injection pump is stationary. It may be used when bleeding

the system.

The gauze filter removes large particles of dust from the fuel

lifted from the fuel tank, preventing the feed pump from

getting clogged. The filter must be washed in clean diesel

periodically.

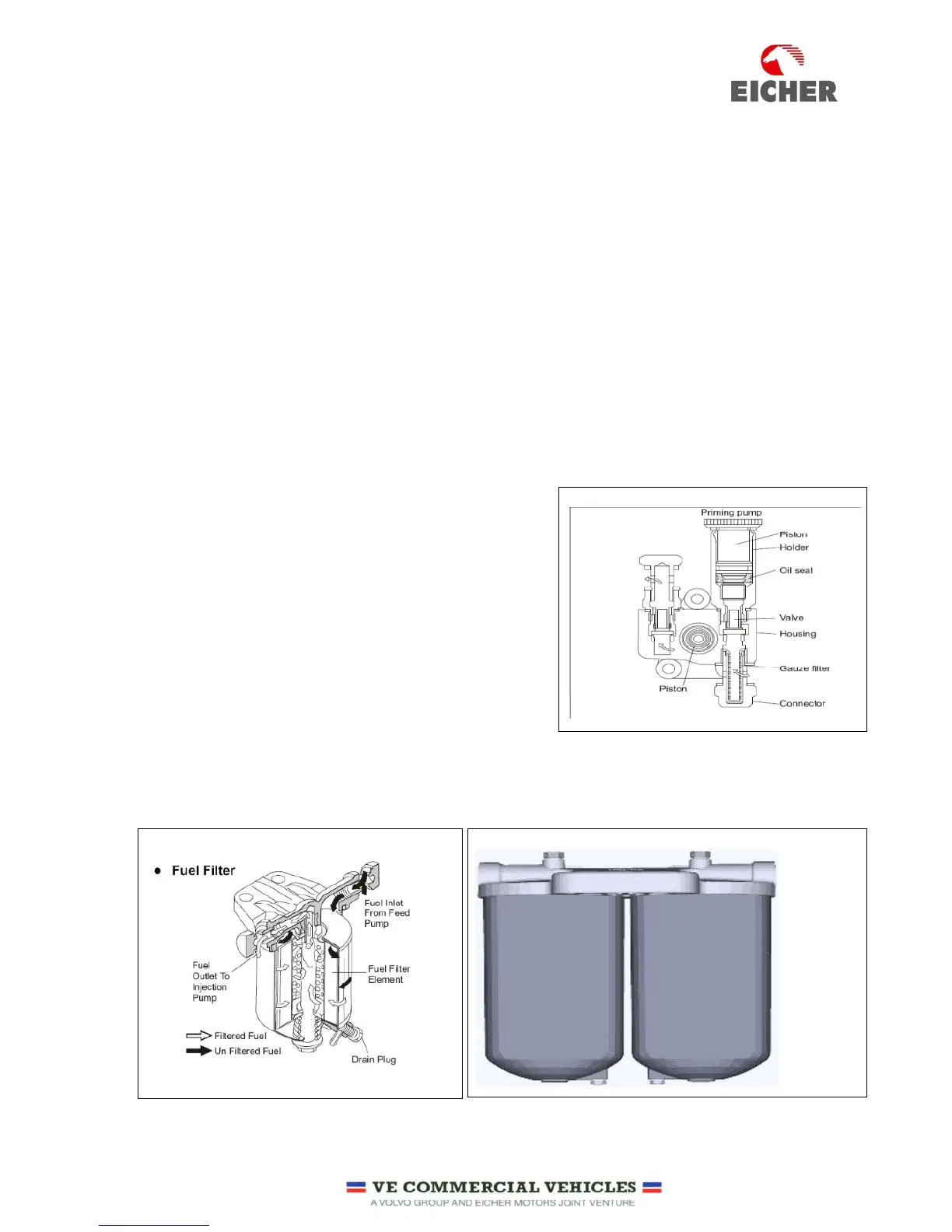

FUEL FILTER:

The fuel from the feed pump is supplied to fuel filter for filtration. The dual filter is of element type and

replaceable individually.

Loading...

Loading...