ELECRAFT 21

Inspect the solder side of U1's socket on the top side of the

board. Make sure all pins are soldered, with no cold solder joints.

Using a DMM, check every pair of adjacent pads on U1 on the

top side of the board (pins 1-20 and 21-40). The resistance between

pads should be over 1000 ohms (1 k) in all cases, and may read

infinite on your DMM (often indicated by a flashing display).

i

Before handling U1 in the next step, touch an unpainted,

grounded metal surface.

Straighten the pins of the microcontroller, U1. You can hold

the IC body at the ends as you re-form each row of pins.

Insert U1 into its socket, with the notched end oriented

towards the pin 1 end of the component outline.

Look at both rows of pins on U1 closely. If any pins are bent,

carefully remove the IC by prying at both ends using a small flat-

blade screwdriver. Straighten the pins using long-nose pliers.

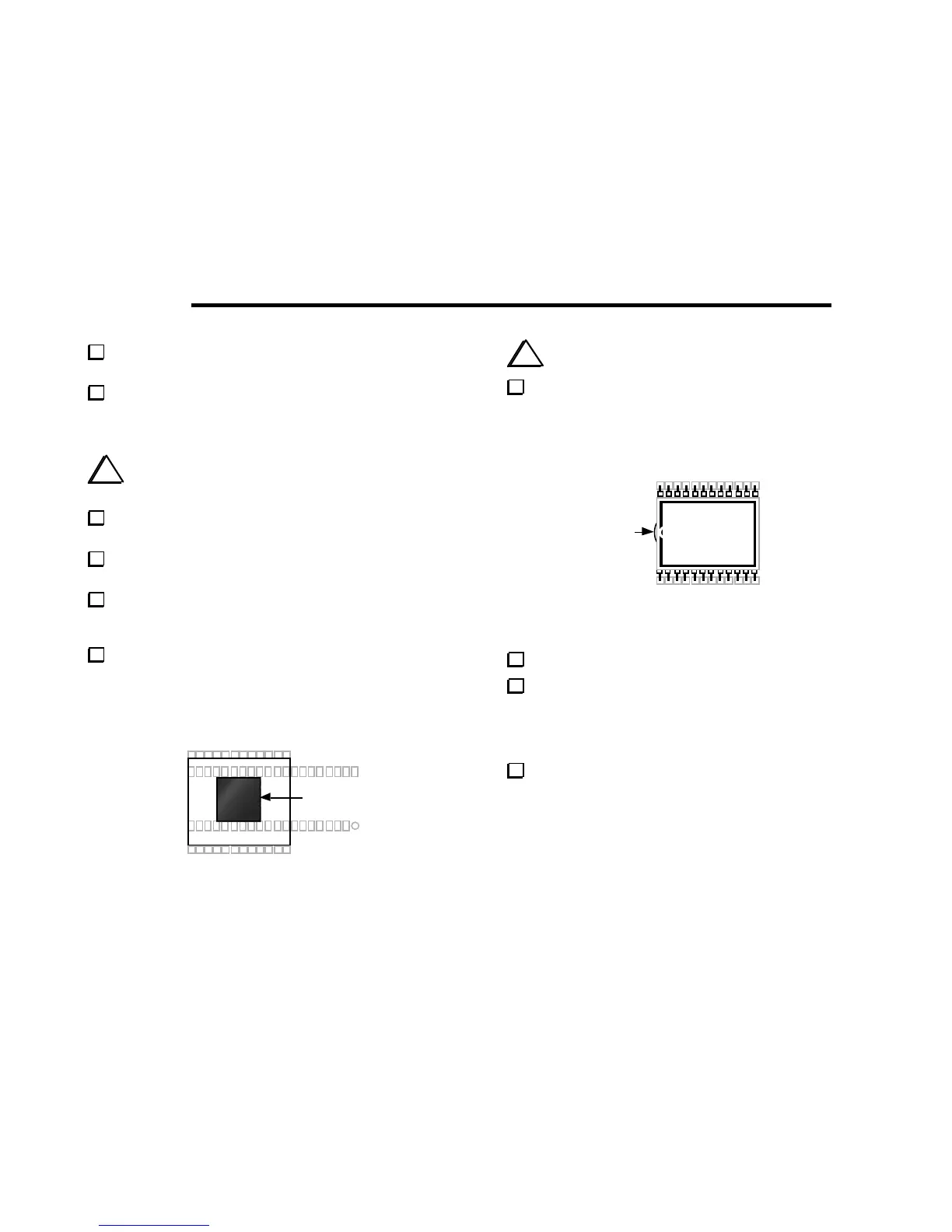

Locate the black neoprene LCD spacer (MISC. bag), which is

1/2 x 1/2 square and 3/16" thick (12 x 12 x 5 mm). Remove the

adhesive backing from one side and position the spacer as shown in

Figure 5-7. It must be mounted flat against the PC board, centered

between the two rows of pins on U1's socket.

Spacer

Figure 5-7

i

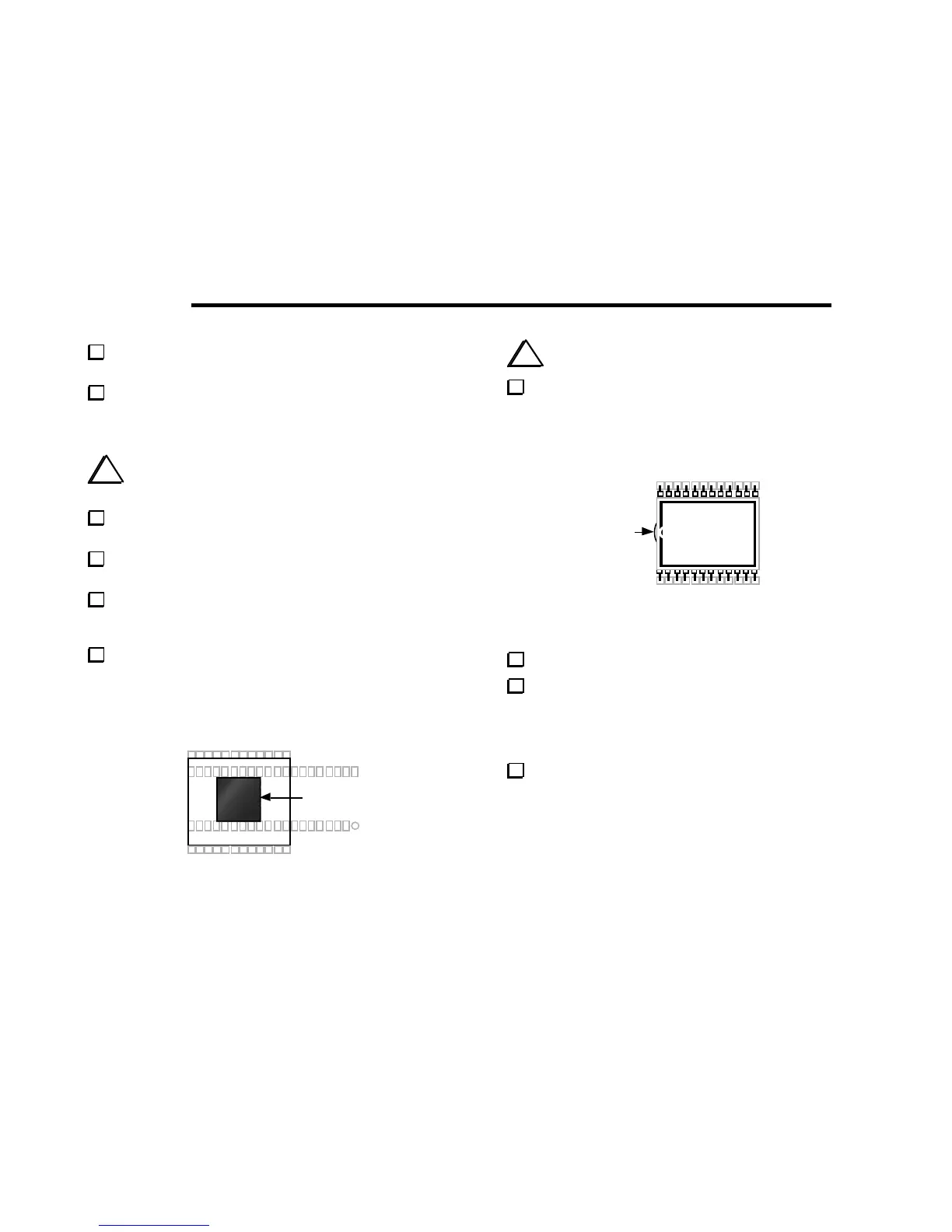

Caution: the LCD (DS1) and its pins are fragile.

Remove the LCD from its packing materials, being careful not

to bend the pins. As shown in Figure 5-8, the pin 1 end of the LCD

glass has a very slight bump, along with a break in the black border.

This end will be oriented towards the pin 1 end of DS1's component

outline.

Bump

DS1

112

13

24

Figure 5-8

Remove the adhesive backing from top side of the LCD spacer.

Install the LCD at DS1, oriented as shown above. Make sure

that all 24 pins are inserted into their holes, then press down gently

on the LCD to secure it to the LCD spacer's adhesive surface. The

LCD pins may not extend all the way through the holes. The

surface of the LCD must be parallel to the PC board.

Once the LCD is positioned correctly, solder all pins.

Loading...

Loading...