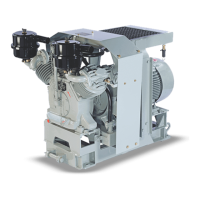

Why is my ELGi Air Compressor overheating?

- DDavid PerezAug 2, 2025

Your ELGi Air Compressor may be overheating due to several reasons: the oil may be dirty, requiring an oil change; the oil level might be low, needing you to fill it to the maximum level with the correct grade of oil; the cylinder and cooler fins could be dirty, requiring cleaning with compressed air or manually; the breather valve may not be working; or the rotation might not be correct, requiring you to interchange two of the incoming power feeds to the motor.