Introduction

The ZPS*KC two-stage modulated Copeland Scroll™

compressors are ideally suited for commercial and light

commercial applications where a capacity stage

reduction and part-load efficiency are desired. The

ZPS*KC is based upon the ZP*KC fixed capacity scroll

compressor and the ZPS*K6 two-stage compressor.

(Reference AE4-1423 for ZPS*K6 and AE4-1365 for

ZP*KC for general application requirements and

recommendations).

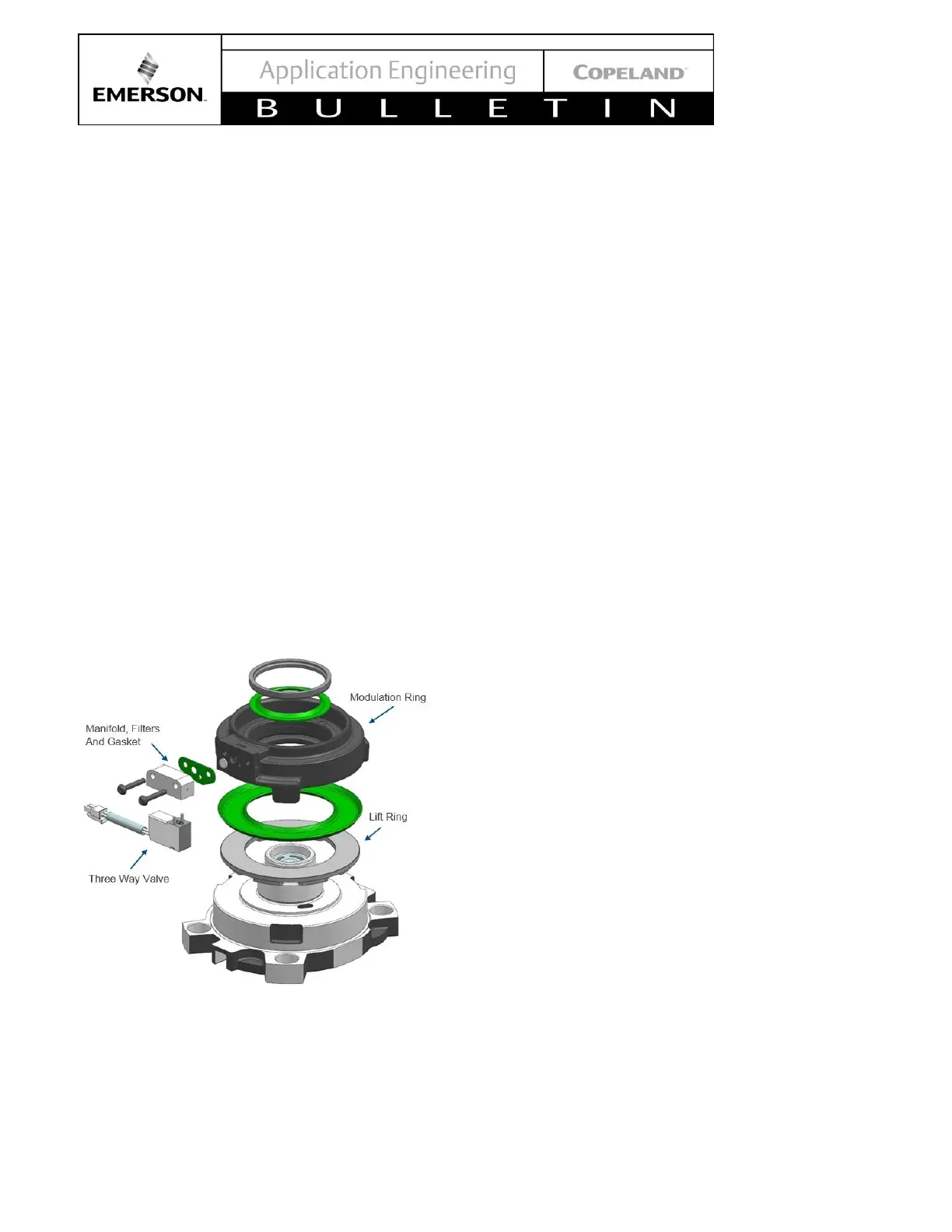

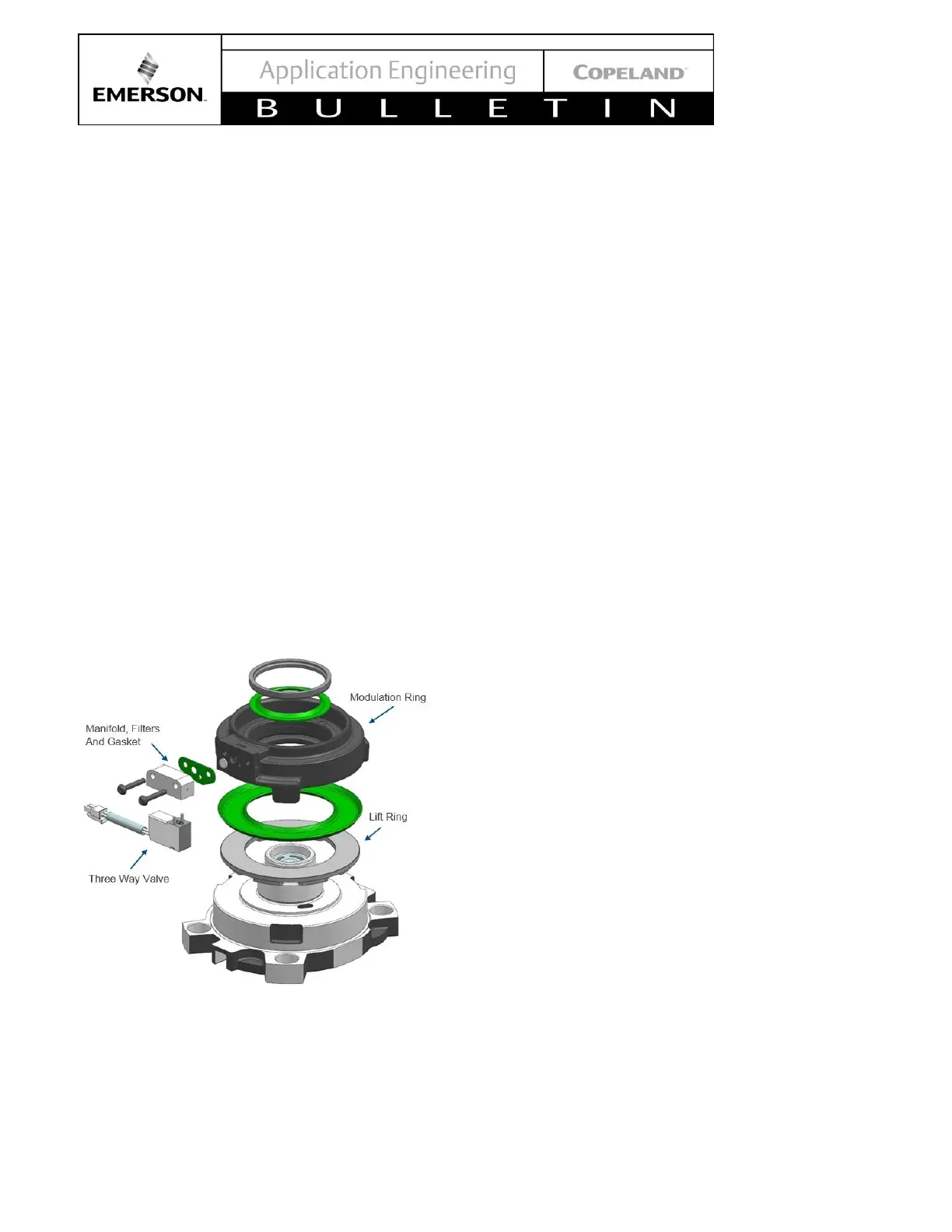

How It Works

A 24-volt DC solenoid valve inside the compressor

provides the means to modulate the compressor.

When the solenoid valve is energized the compressor

is in full-load and when de-energized the compressor

is in part-load. When the ZPS*KC solenoid is

energized a 3-way solenoid valve provides pressure to

a lift ring assembly that is used to open and close the

scroll modulation ports. A single-speed motor

continues to run while the scroll modulates between

the two capacity stages. See Figure 1 for hardware

pictorial.

Figure 1 ZPS*KC

Capacity Control

The compression process of a scroll compressor

is described in AE4-1365, Figure 8. At any point in

the compression process, there are several pockets

within the scroll that are compressing gas. Modulation

is achieved by venting a portion of the gas in the first

suction pocket back to the low side of the compressor

thereby reducing the effective displacement of the

compressor. Full capacity is achieved by blocking

these ports, thus increasing the displacement to 100%.

When the solenoid is energized, the compressor is in

full-load or 100% of its capacity. When the solenoid

is de-energized the compressor is in part-load or

approximately 67% of its full-load capacity. The loading

and unloading of the two-stage scroll are done “on the

fly” without shutting off the motor between stages. The

unloaded mode default was chosen for two reasons:

1. It is expected that most run hours will be in a low

capacity, part-load mode.

2. It allows a simple two-stage thermostat to control

capacity through the second stage in both cooling and

heating.

Nomenclature

The model numbers of the Copeland Scroll

compressors include the approximate nominal 60Hz

capacity at AHRI operating conditions of 45°F(7.2°C)

evaporating temperature and 130°F (54.4°C)

condensing temperature. An example would be the

ZPS83KCE-TF5 which has 83,000 Btu/hr (24.3. kW) at

the above mentioned full-load condition. Both full and

part-load performance data are published throughout

the entire operating envelope and can be found in the

Online Product Information(OPI) at Emerson.com/OPI

APPLICATION CONSIDERATIONS

In most respects, the two-stage scroll will

operate like a standard scroll in both the high and

low capacity mode. The basic application guidelines

in AE4-1365 should be adhered to for ZPS*KC

compressors. There are a few important differences

outlined below that must be observed when designing

a system with the Copeland Scroll ZPS*KC two-stage

compressor.

Operating Envelope

The ZPS*KC compressor family is approved for use

with R410a only. The ZPS*KC compressors can

operate at full-load capacity throughout the entire

specified operating envelope, see Figure 2. There are

operating envelope limitations in part load. Contact

Application Engineering for more information. The

envelope represents acceptable operating conditions

Loading...

Loading...