10

850 and 950 Series

North America Only

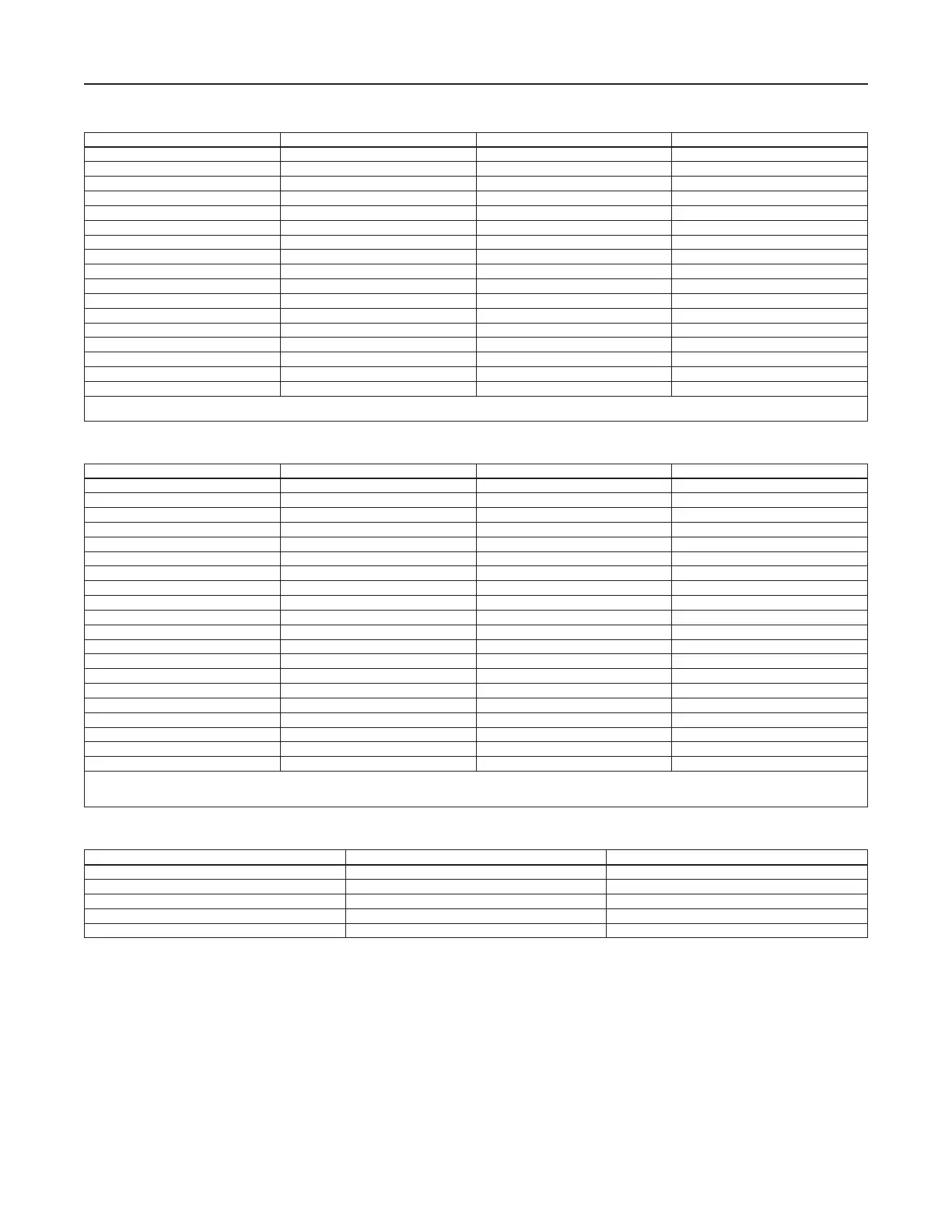

Table 1. Torque Specifications - Raised Face Flange, Steel Only

NOMINAL PIPE DIAMETER NUMBER OF BOLTS BOLT DIAMETER, IN. TORQUE, FT-LBS

1 4 0.50 9

1-1/4 4 0.50 13

1-1/2 4 0.50 18

2 4 0.63 35

2-1/2 4 0.63 41

3 4 0.63 60

3-1/2 8 0.63 34

4 8 0.63 43

6 8 0.75 80

8 8 0.75 109

10 12 0.88 101

12 12 0.88 135

14 12 1.00 168

16 16 1.00 159

18 16 1.13 244

20 20 1.13 214

24 24 1.25 253

Assumptions: Use of SAE grade 5 bolts or studs or stronger. No lubricant. Compressed mineral ber material or similar.

Notes: If lubricant is used on bolts, apply torque reduction factor listed in Table 3. For best results, hardened steel washers should be used on all cast ange bolted connections.

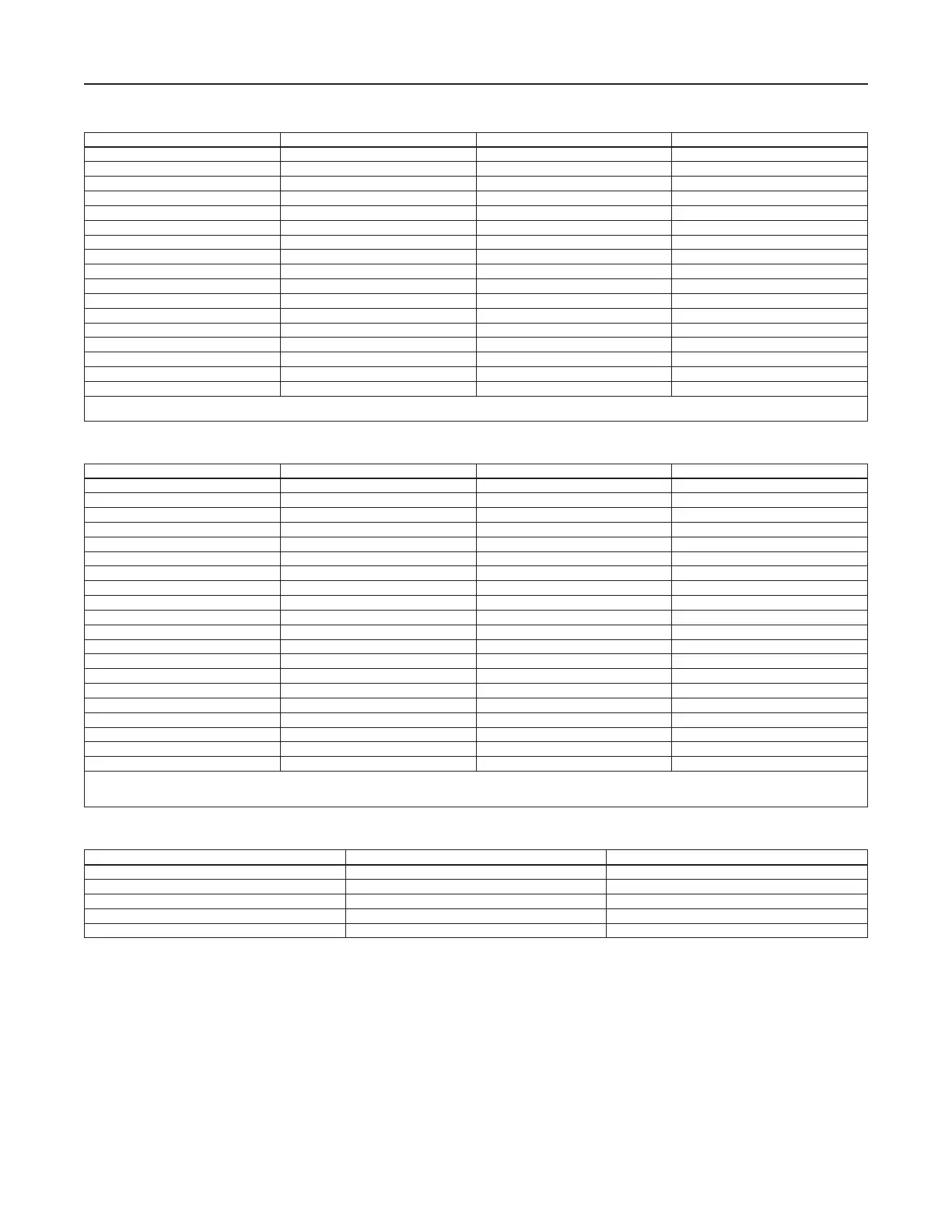

Table 2. Torque Specifications - Flat Face Flange, Steel or Aluminum

NOMINAL PIPE DIAMETER NUMBER OF BOLTS BOLT DIAMETER, IN. TORQUE, FT-LBS

1 4 0.50 14

1-1/4 4 0.50 16

1-1/2 4 0.50 18

2 4 0.63 32

2-1/2 4 0.63 43

3 4 0.63 47

3-1/2 8 0.63 26

4 8 0.63 32

6 8 0.75 49

8 8 0.75 68

10 12 0.88 69

12 12 0.88 98

14 12 1.00 138

16 16 1.00 125

18 16 1.13 142

20 20 1.13 135

24 24 1.25 156

8 API 16 0.50 20

20 API 16 0.63 75

24 API 20 0.63 75

Assumptions: Use of SAE grade 5 bolts or studs or stronger. No lubricant. Elastomer <70 Durometer Shore A.

Notes: Flat faced anges should never be mated to a raised face ange for installation. If lubricant is used on bolts, apply torque reduction factor listed in Table 3. For best results,

hardened steel washers should be used on all cast ange bolted connections.

Table 3. Torque Reduction Factors per Lubricant

DESCRIPTION COEFFICIENT OF FRICTION MULTIPLY TORQUE VALUE IN TABLE BY

Machine Oil f = 0.15 0.75

API SA2 Grease f = 0.12 0.60

Nickel-based Lubricant f = 0.11 0.55

Copper-based Lubricant f = 0.10 0.50

Heavy-Duty Lubricating Paste f = 0.06 0.30

Loading...

Loading...