5

850 and 950 Series

North America Only

• Cert. No. (Certicate Number) – Ex. 10273X

• Pressure

- Setting – Ex. Z4.0

- Flow Rate SCFH (Air) – Ex. 00000

• Vacuum

- Setting – Ex. Z0.5

- Flow Rate SCFH (Air) – Ex. 00000

Principle of Operation

850 and 950 Series

The 850 and 950 Series pressure/vacuum relief valves The 850 and 950 Series pressure/vacuum relief valves

maintain a tight seal until system pressure or vacuum maintain a tight seal until system pressure or vacuum

exceeds the set pressure of the valve. Set pressure exceeds the set pressure of the valve. Set pressure

is determined by stacking a series of weights onto the is determined by stacking a series of weights onto the

valve pallet unless the pressure and vacuum set points valve pallet unless the pressure and vacuum set points

have been specied for the minimum settings. When have been specied for the minimum settings. When

overpressure occurs, the weighted pallet lifts, breaking overpressure occurs, the weighted pallet lifts, breaking

the seal between the seat and pallet. This allows the seal between the seat and pallet. This allows

vapors to pass through the valve orice and relieve vapors to pass through the valve orice and relieve

pressure buildup. The valve reseals upon relief and pressure buildup. The valve reseals upon relief and

remains sealed.remains sealed.

It is important to know that relieving vapors near the It is important to know that relieving vapors near the

set pressure in a continuous manner may cause the set pressure in a continuous manner may cause the

pallet to utter or oscillate inside the valve chamber. pallet to utter or oscillate inside the valve chamber.

This is common to products of this type. Operating the This is common to products of this type. Operating the

valve with utter or oscillation may cause premature valve with utter or oscillation may cause premature

valve damage or wear over time. Enardo pressure/valve damage or wear over time. Enardo pressure/

vacuum relief valve ow charts and sizing program vacuum relief valve ow charts and sizing program

results designate the “utter zone” to assist with correct results designate the “utter zone” to assist with correct

valve sizing. valve sizing. Contact your local Sales Oce with any

questions or additional assistance.

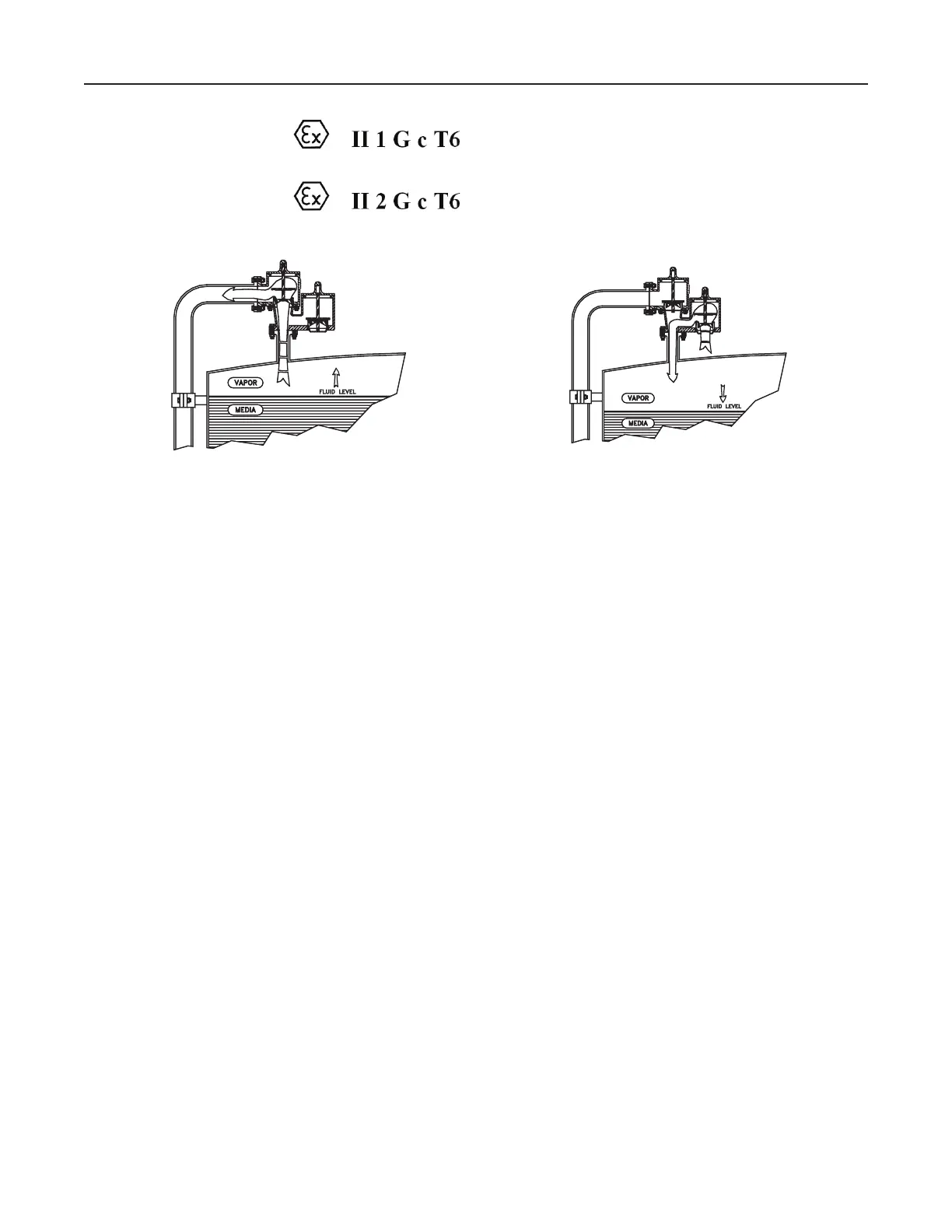

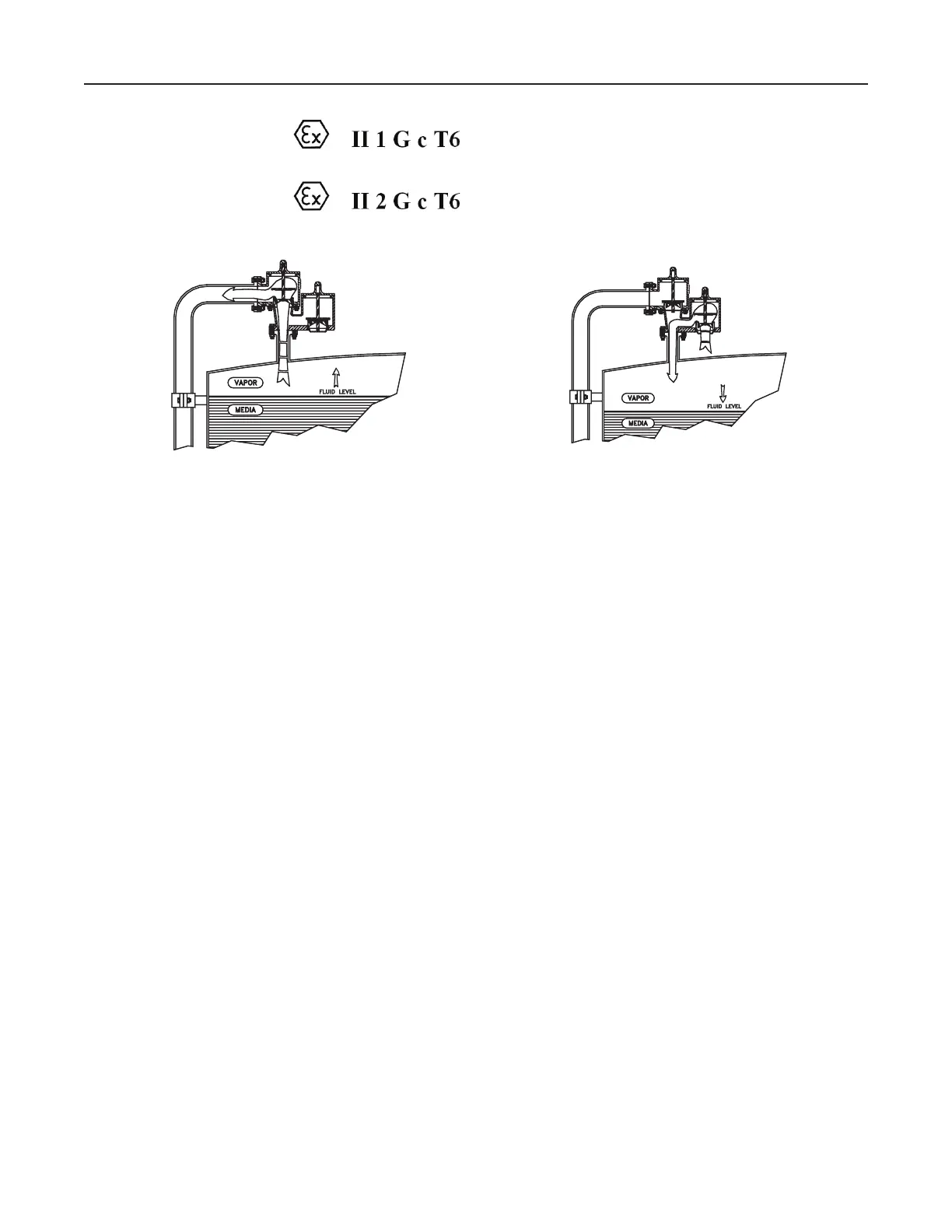

Figure 6. Pressure and Vacuum Flow

PRESSURE FLOW VACUUM FLOW

Figure 5. Product Identification and Marking

OUTER HOUSING OF UNCOATED ALUMINUM

OUTER HOUSING OF STAINLESS STEEL,

CARBON STEEL OR COATED ALUMINUM

Smart Wireless Monitoring Operation

The Smart Wireless Monitored PVRV design consists

of the PVRV, proximity sensors and a wireless

transmitter. The built-in proximity sensors detect the

open or closed position of the valve stem and send

these signals to the transmitter. These signals received

by the transmitter can then be sent to a control room

via a WirelessHART Gateway.

WirelessHART is a wireless sensor networking

technology that is based on the Highway Addressable

Remote Transducer (HART) protocol. It was developed

as a multi-vendor, interoperable wireless standard for

process field device networks. It is the most widely

used standard today and, for this reason, the PVRV

described herein was designed to integrate within it.

As long as the wireless gateway is WirelessHART,

it will receive the signal from the device. The

WirelessHART gateway will then send the information

to a control room which makes use of any number of

software integration packages.

Loading...

Loading...