Instruction Manual

D101550X012

8532 Valve

June 2017

5

Valve Orientation

The valve can be installed in any orientation, however it is recommended that the valve drive shaft be horizontal and

the actuator vertical as shown in figure 4.

Install the valve with the high‐pressure shutoff side in the direction noted by the flow arrow for proper installation, and

see figure 4 for more information.

Before Installing the Valve

WARNING

The edges of a rotating valve disk (key 2, figure 9 or 10) close with a shearing, cutting motion. To avoid personal injury,

keep hands, tools, and other objects away from the disk while stroking the valve.

If the 8532 valve is equipped with a fail‐open actuator, cycle the valve into the fully closed position. Ensure the valve cannot

open during installation by using travel stops, a manual actuator, a constant supply pressure to the pneumatic actuator, or

other steps as necessary.

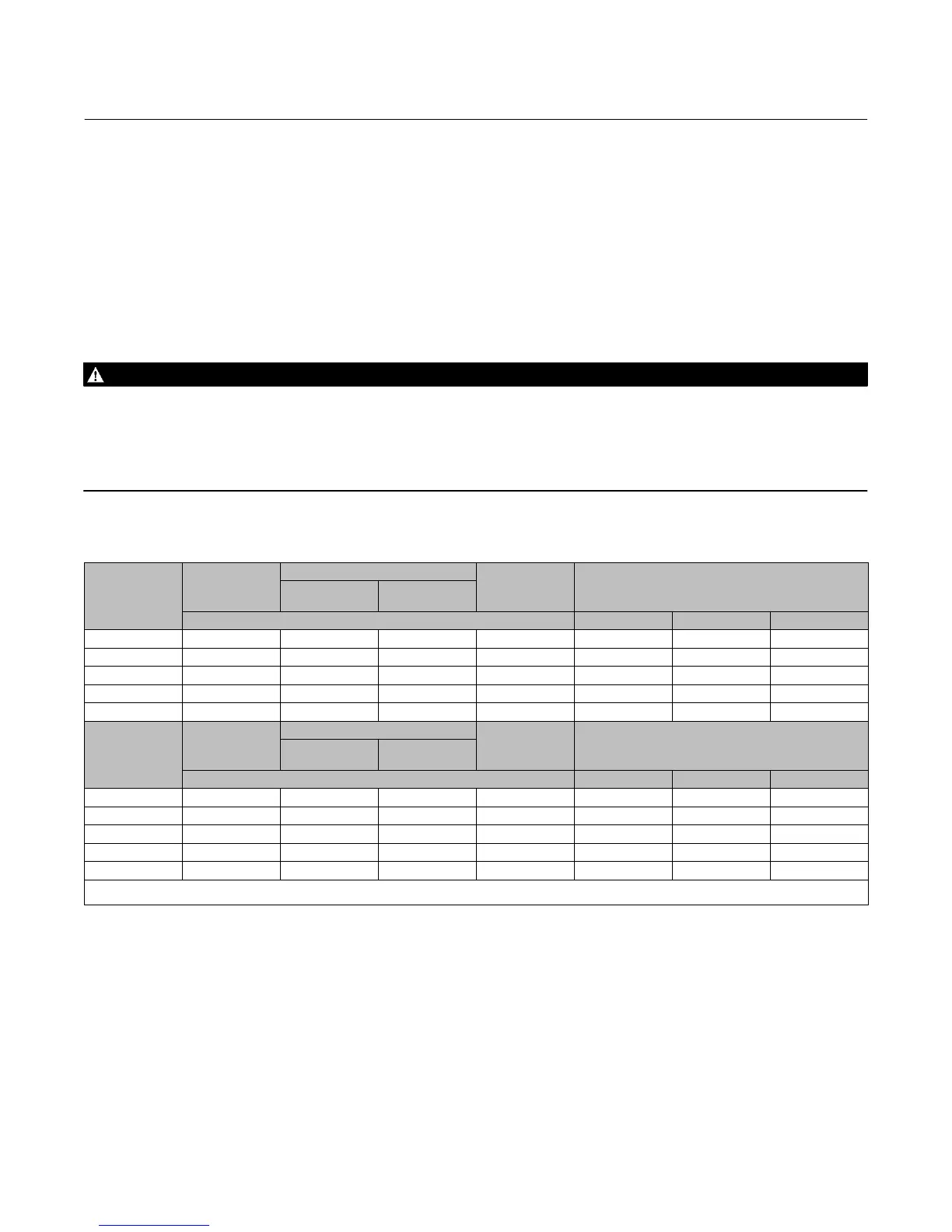

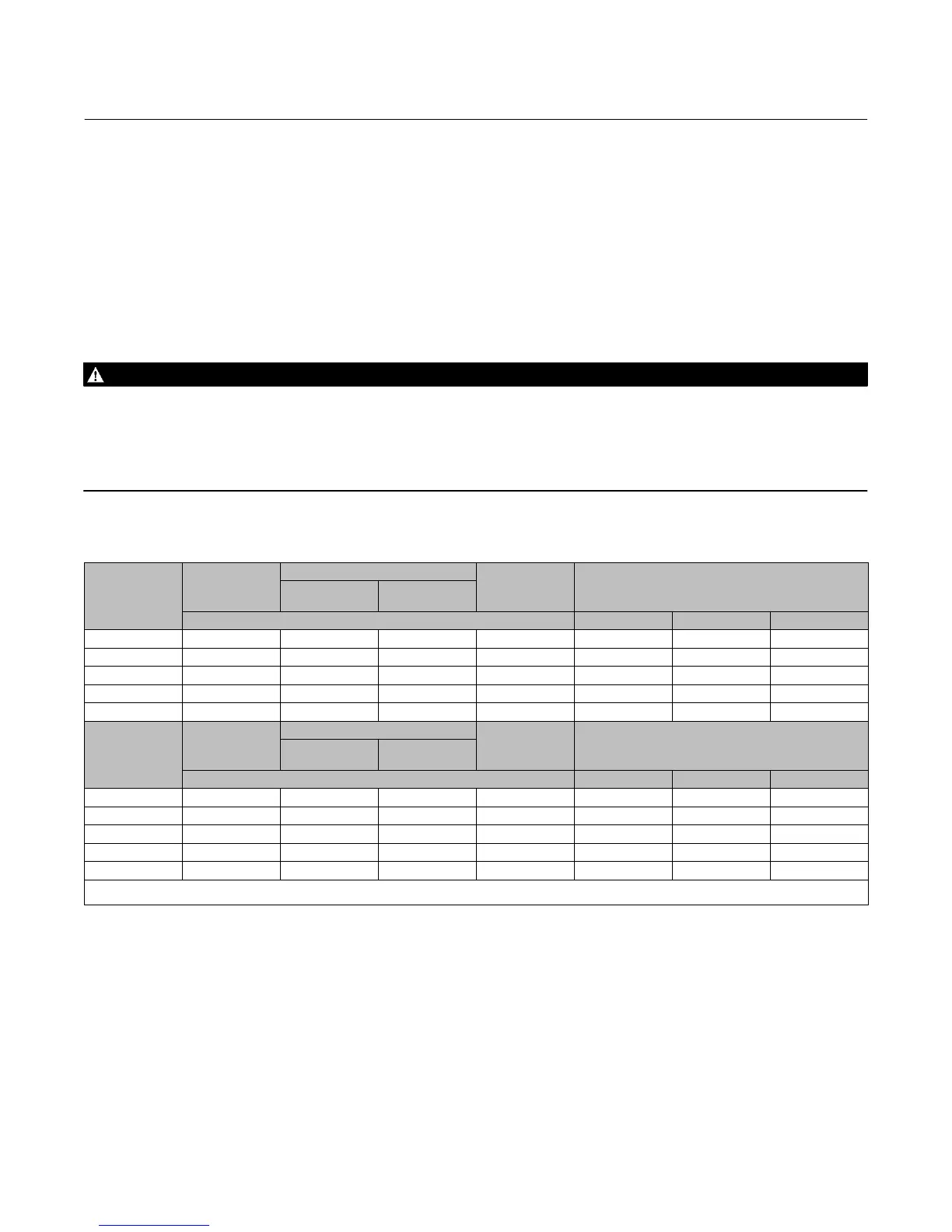

Table 3. Valve Body Data, CL150

VALVE SIZE,

NPS

SHAFT DIA. AT

YOKE BEARING

FACE‐TO‐FACE DIMENSION

(1)

MINIMUM

I.D

.(2)

APPROXIMATE WEIGHT, KILOGRAMS

Wafer and

Lugged

Double-Flange

mm Wafer Lugged Double-Flange

14 30.2 92.1 191 331.2 71.7 94.8 152

16 31.75 101.6 216 375.2 93.9 137.9 201

18 38.1 114.3 222 418.8 139.3 178.3 243

20 44.45 127.0 229 464.1 166.9 223.6 277

24 57.15 154.0 267 580.9 255.4 350.6 434

VALVE SIZE,

NPS

SHAFT DIA. AT

YOKE BEARING

FACE‐TO‐FACE DIMENSION

(1)

MINIMUM

I.D

.(2)

APPROXIMATE WEIGHT, POUNDS

Wafer and

Lugged

Double-Flange

Inches Wafer Lugged Double-Flange

14 1‐3/16 3.625 7.50 13.04 158 209 335

16 1‐1/4 4 8.50 14.77 207 304 443

18 1/2 4.5 8.75 16.49 307 393 535

20 1‐3/4 5 9.00 18.27 368 493 611

24 2‐1/4 6.0625 10.50 22.87 563 773 956

1. Face‐to‐face dimensions are in compliance with MSS SP68 and API 609 specifications.

2. Minimum I.D. is the minimum pipe or flange I.D. required for disk swing clearance. Applies to wafer and lugged valve bodies only.

Loading...

Loading...