Y600A Series

4

Body Area

This procedure is for gaining access to the disk assembly,

orice, body O-ring, and pitot tube if used. All pressure

must be released from the diaphragm casing, and the

disk assembly must be open, before these steps can

be performed.

1. Remove the cap screws (key 2) and separate the

diaphragm casing (key 4) from the body (key 1).

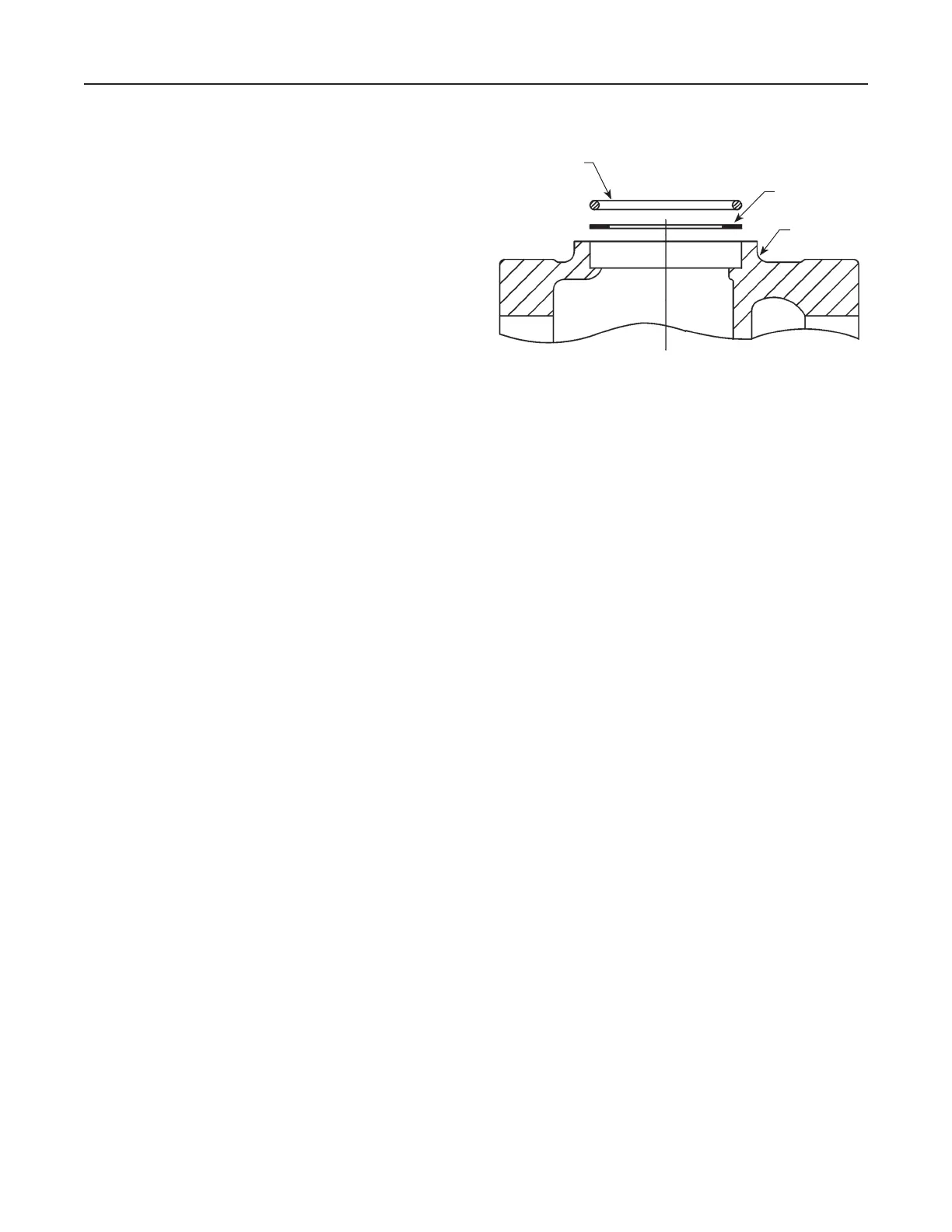

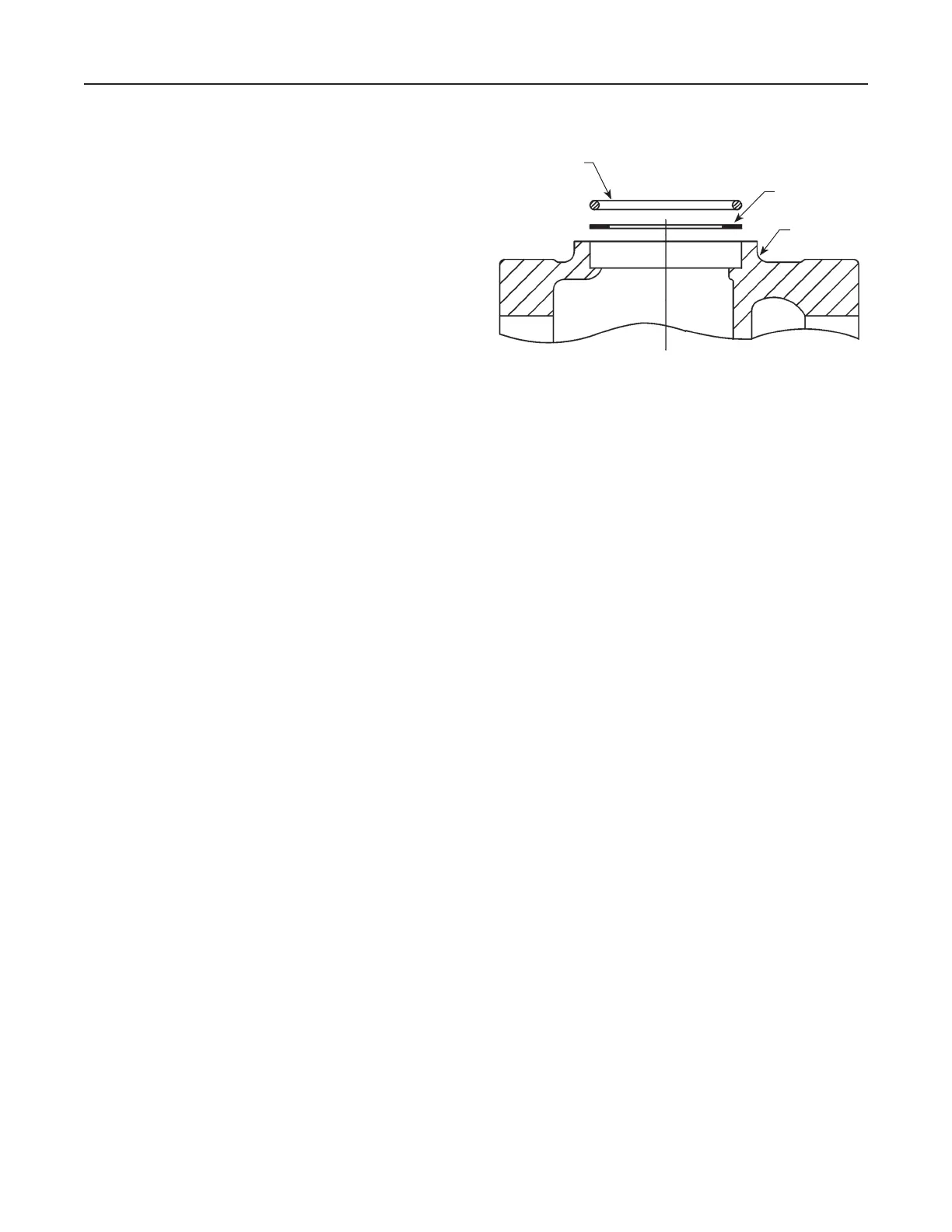

2. Remove and inspect the body seal O-ring (key 11) and

the backup ring (key 48). See Figure 2.

3. Inspect and replace the orice (key 5) if necessary.

Protect the orice seating surface during disassembly

and assembly. Lubricate the threads of the

replacement orice with a good grade of light grease

and install with 29 to 37 foot-pounds (39 to 50 N•m)

of torque.

4. To replace the disk assembly (key 13), remove the

cotter pin (key 15). If not necessary, skip to step 7.

5. To replace the pitot tube (key 32, Figures 3 and 6) on

the Types Y600A and Y600AR, remove the machine

screws (key 33), install the new pitot tube, and secure

with the machine screws. Position the pitot tube so

that it points into the outlet of the body (key 1) by

rotating the guide insert (key 18).

6. Install the disk assembly (key 13) and secure it with

the cotter pin (key 15).

7. Place backup ring (key 48) into the body (key 1).

Then place the body seal O-ring (key 11) into the

body. See Figure 2.

8. Place the diaphragm casing (key 4) on the body

(key 1). Secure the the diaphragm casing to the body

with the cap screws (key 2) using 7 to 9 foot-pounds

(9 to 12 N•m).

Diaphragm and Spring Case Area

This procedure is for gaining access to the spring,

diaphragm, lever assembly stem, and Type Y600AM

stem O-ring. All pressure must be released from the

diaphragm casing before performing these steps.

Note

Any Type 662 remote control drive unit

used with a Y600A Series regulator must

be removed from the spring case (key 3)

before these steps can be performed.

1. Remove the closing cap (key 22), and turn the

adjusting screw (key 35) counterclockwise to remove

the compression from the spring (key 6).

2. If the only maintenance is to change the control

spring, take out the control spring and replace with

the desired spring. Turn the adjusting screw (key 35)

clockwise to compress the spring to the desired outlet

pressure setting. Skip to step 11.

3. If further maintenance to the internal diaphragm

casing parts is required, remove the hex nuts (key 23,

not shown) and cap screws (key 24). Remove the

diaphragm (key 10) plus attached parts by tilting

them so that the pusher post (key 8) slips off the lever

assembly (key 16). To separate the diaphragm from

the attached parts, unscrew the cap screw (key 38,

Figures 3 and 4) from the pusher post (key 8)

for a Type Y600A or Y600AM, or unscrew the relief

valve spring holder (key 37, Figure 6) from the pusher

post (key 8) for a Type Y600AR. If the only further

maintenance is to replace the diaphragm parts, skip

to step 7.

4. To replace the lever assembly (key 16), remove the

machine screws (key 17). To replace the stem

(key 14) or the Type Y600AM stem O-ring (key 30,

Figure 4), also perform Body Area Maintenance

procedure steps 1 and 4, and pull the stem (key 14)

out of the diaphragm casing (key 4). With a Type

Y600AM, grease the replacement stem O-ring

(key 30, Figure 4) with a good grade of lubricant and

install it on the tem (key 14).

5. Install the stem (key 14) into the diaphragm casing

(key 4) and perform Body Area Maintenance

procedure steps 6 through 8 as necessary.

Figure 2. Expanded View of the Body Area Showing

the Body Seal O-ring and Backup Ring Placement

BODY SEAL

O-RING (KEY 11)

BACKUP RING

(KEY 48)

BODY (KEY 1)

Loading...

Loading...