5

MR98 Series AD2000 Compliant

D-A-CH Region Only

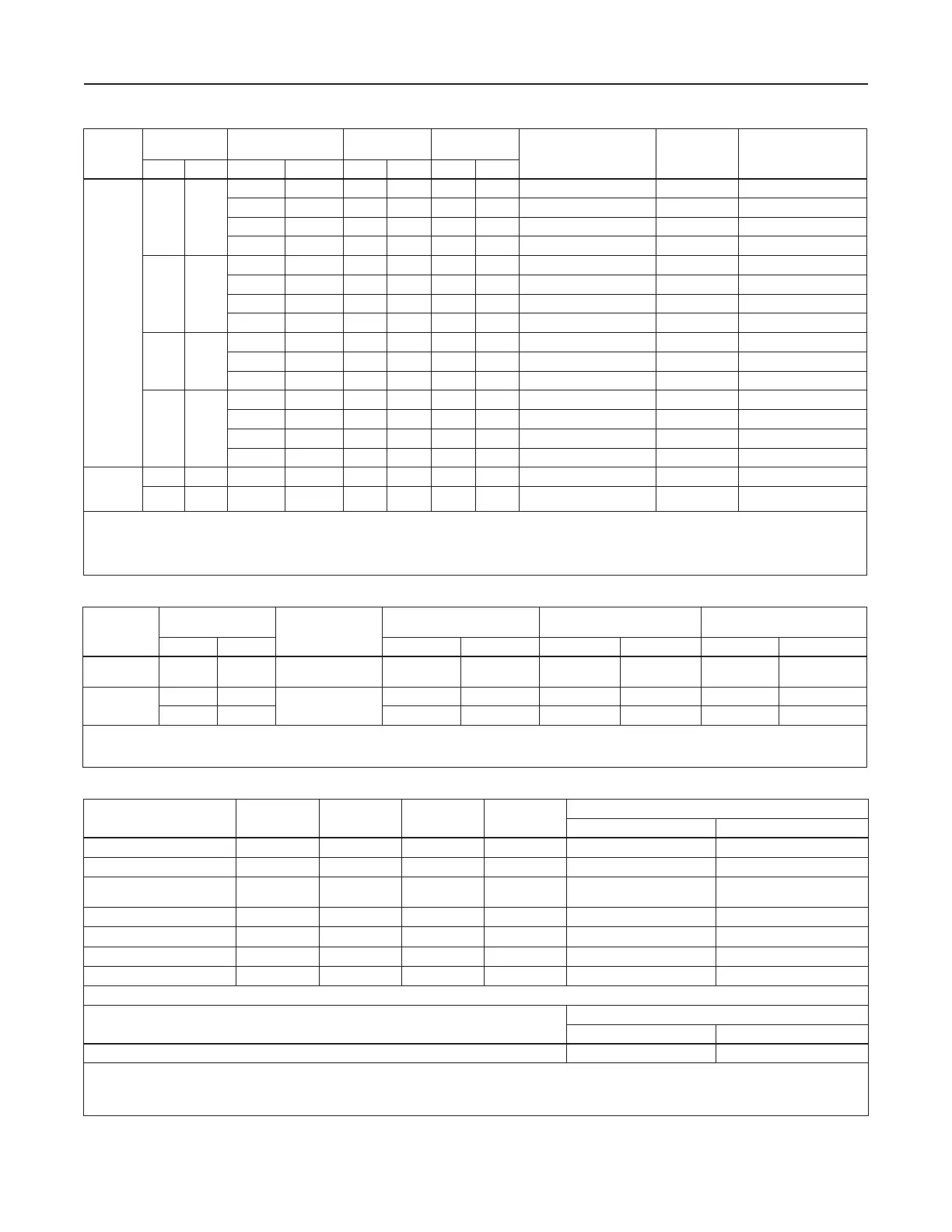

Table 2. MR98 Series Body Sizes, Pressure Ranges and Spring Information

TYPE

BODY SIZE

CONTROL

PRESSURE RANGE

(1)

SPRING WIRE

DIAMETER

SPRING FREE

LENGTH

SPRING MATERIAL

(2)

SPRING PART

NUMBER

SPRING COLOR

NPS DN psig bar In. mm In. mm

MR98H

1/2 15

15 to 35 1.0 to 2.4 0.207 5.26 2.50 63.5 Powder-coated steel

(3)

ERCA04288A0 Yellow

25 to 75 1.7 to 5.2 0.234 5.94 2.595 65.9 Powder-coated steel

(3)

ERAA01910A0 Green

70 to 140 4.8 to 9.7 0.283 7.19 2.44 62.0 Powder-coated steel

(3)

ERAA01911A0 Red

130 to 200 9.0 to 13.8 0.331 8.41 2.250 57.2 Powder-coated steel

(3)

ERAA02889A0 Blue

3/4

and 1

20

and 25

15 to 35 1.0 to 2.4 0.306 7.77 4.00 102 Powder-coated steel

(3)

1E398927022 Yellow

25 to 75 1.7 to 5.2 0.343 8.71 4.00 102 Powder-coated steel

(3)

1E399027142 Green

70 to 140 4.8 to 9.7 0.406 10.3 4.00 102 Powder-coated steel

(3)

1E399127162 Red

130 to 200 9.0 to 13.8 0.468 11.9 3.75 95.3 Powder-coated steel 1L380127082 Blue

3/4

and 1

20

and 25

15 to 35 1.0 to 2.4 0.306 7.77 4.00 102 Powder-coated Stainless steel 1E3989X0052 Yellow

25 to 75 1.7 to 5.2 0.375 9.53 3.88 98.6 Stainless steel 1K762537022 Unpainted

70 to 140 4.8 to 9.7 0.437 11.1 4.00 102 Stainless steel 11A8269X012 Unpainted

1-1/2

and 2

40

and 50

5 to 35 0.34 to 2.4 0.468 11.9 6.562 167 Powder-coated steel

(4)

1E792327092 Dark gray

20 to 65 1.4 to 4.5 0.500 12.7 6.50 165 Powder-coated steel

(4)

ERCA04290A0 Black with light blue stripe

50 to 100 3.4 to 6.9 0.562 14.3 6.562 167 Powder-coated steel

(5)

ERAA01893A0 Light gray

75 to 170 5.2 to 11.7 0.625 15.9 6.565 167 Powder-coated steel

(5)

1P7888X0022 Black

MR98HH

1/2 15 150 to 375 10.3 to 25.9 0.394 10.0 5.063 129 Powder-coated steel 1N943427142 Unpainted

3/4

and 1

20

and 25

150 to 340 10.3 to 23.4 0.593 15.1 6.380 162 Chromium-silicon steel 1N9441X0022 Light gray

1. All springs may be backed o to 0 psig / 0 bar. However, highest capacities and best performances are obtained by using these springs in their recommended ranges.

2. Springs meet NACE MR0175-2002, NACE MR0103 and NACE MR0175/ISO 15156 requirements only for applications in which the spring is not exposed to the sour gas.

3. Available in Inconel

®

.

4. Spring range changes to 5 to 60 psig / 0.34 to 4.1 bar for the Inconel

®

option.

5. Spring range changes to 50 to 120 psig / 3.4 to 8.3 bar for the Inconel

®

option.

Inconel

®

is a mark owned by Special Metals Corporation.

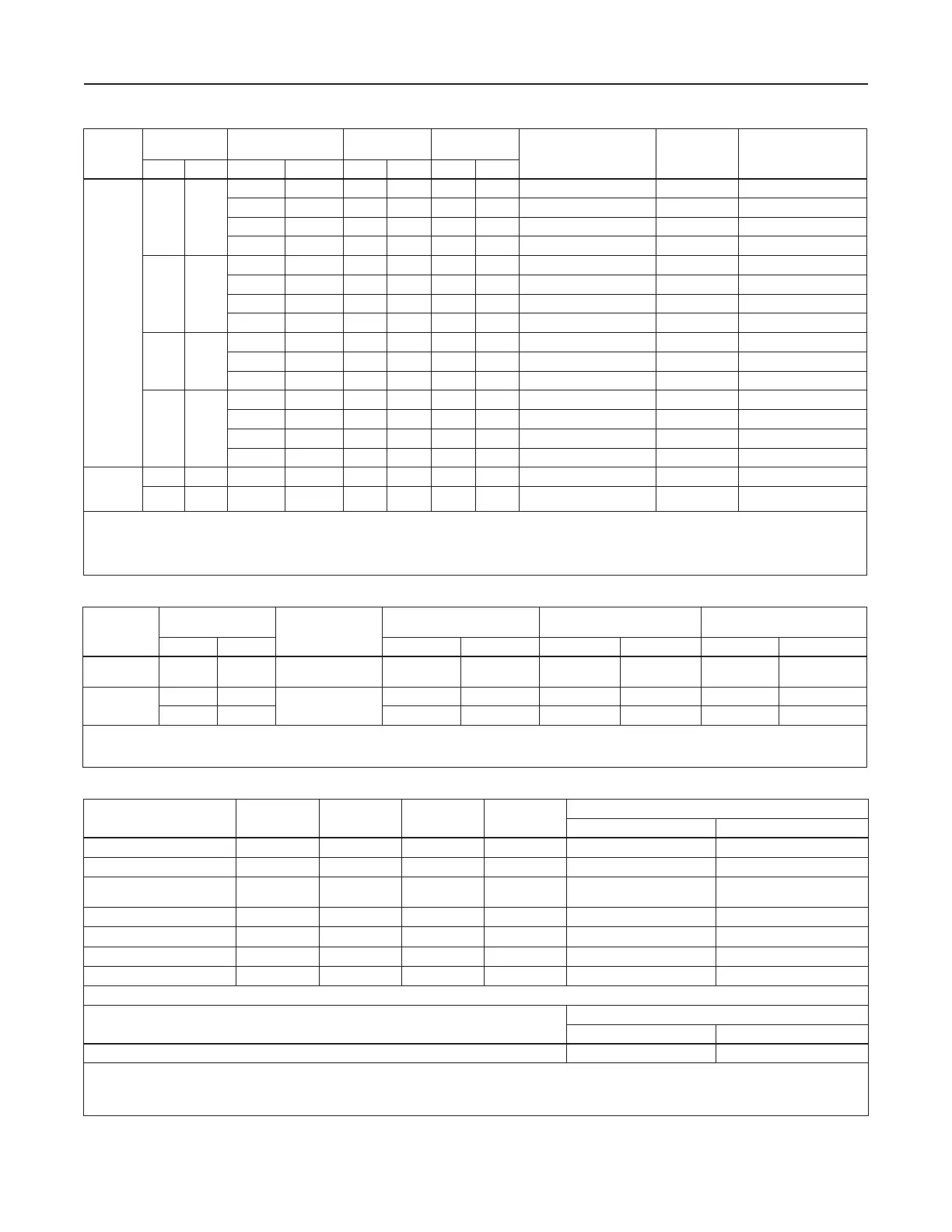

Table 3. Maximum Cold Working Pressures of Body Size and Materials

(1)(2)

REGULATOR

TYPE

BODY SIZE

BODY AND SPRING

CASE MATERIALS

MAXIMUM INLET PRESSURE

(3)

MAXIMUM OUTLET PRESSURE

MAXIMUM SPRING

CASE PRESSURE

NPS DN psig bar psig bar psig bar

MR98H

1/2, 3/4, 1,

1-1/2, 2

15, 20, 25,

40, 50

Stainless steel 300 20.7 300 20.7 300 20.7

MR98HH

1/2 15

Stainless steel

400 27.6 400 27.6 400 27.6

3/4, 1 20, 25 340 23.4 340 23.4 340 23.4

1. The pressure/temperature limits in this Installation Manual and any applicable standard limitation should not be exceeded.

2. Temperature, trim material and/or the body end connection may decrease these maximum pressures.

3. Maximum inlet pressure equals set pressure plus build-up.

Table 4. Temperature Capabilities

(1)(2)(5)

MATERIAL SEAT DIAPHRAGM O-RING

DIAPHRAGM

PROTECTOR

TEMPERATURE

°F °C

Nitrile (NBR)

-40 to 180 -40 to 82

Neoprene (CR)

-40 to 180 -40 to 82

Fluorocarbon (FKM)

(3)

0 to 300,

Limited to 200°F for hot water

-18 to 149,

Limited to 93°C for hot water

Ethylenepropylene (EPDM)

20 to 275 -7 to 135

Peruoroelastomer (FFKM)

0 to 425 -18 to 218

PTFE

-40 to 400 -40 to 204

Metal

-40 to 450 -40 to 232

BODY MATERIAL

TEMPERATURE

°F °C

1.4408 Stainless steel

(4)

-40 to 450 -40 to 232

1. The pressure/temperature limits in this Instruction Manual and any applicable standard limitation should not be exceeded.

2. Pressure and/or the body end connection may decrease these maximum temperatures.

3. Not for use on steam service.

4. Meets API 614 requirements (with Stainless steel trim).

Loading...

Loading...