This unit is shipped with the Micromotor, Straight Handpiece, Prophy Angle, starter supply of Cups and Paste.

STRAIGHT HANDPIECE MAINTENANCE

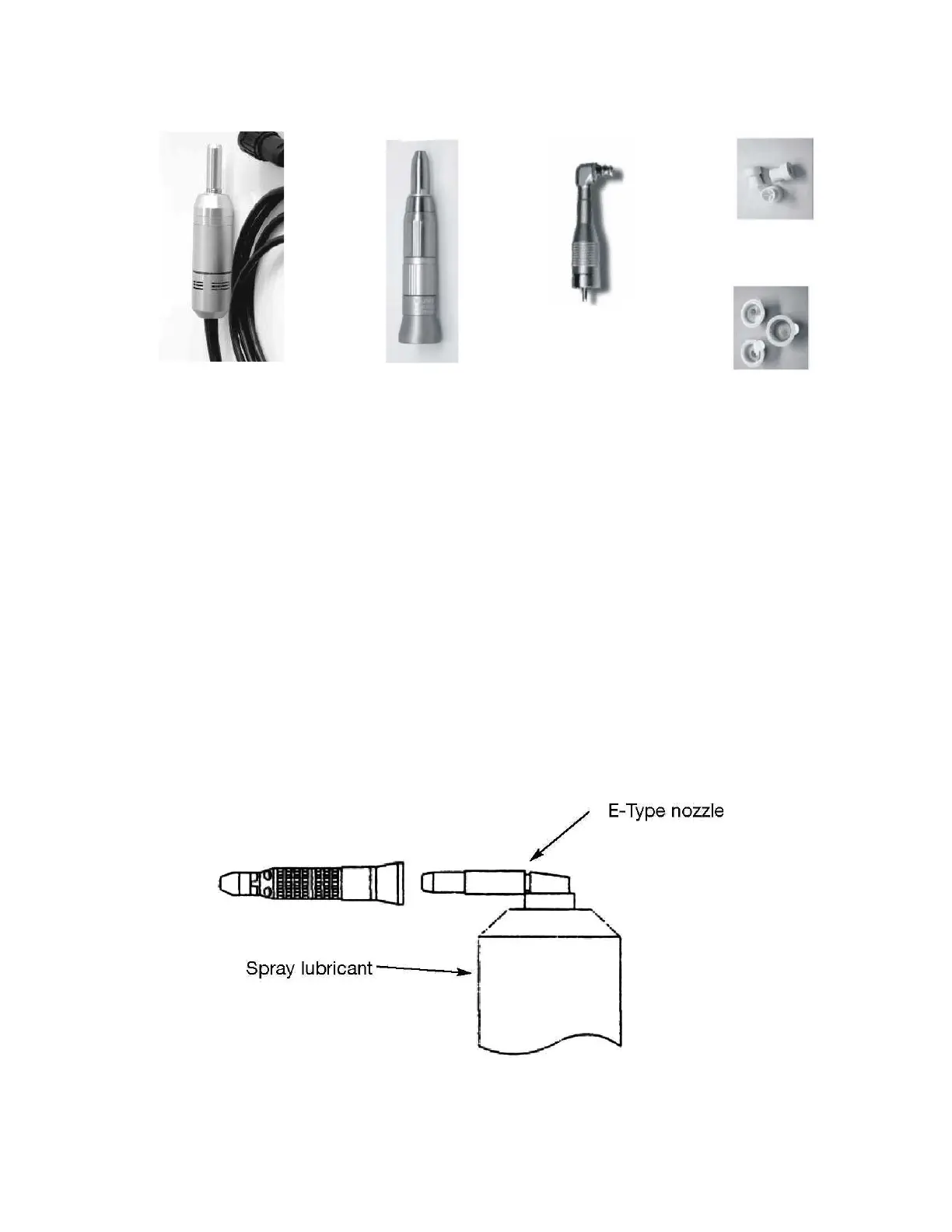

The spray nozzle oiling method is optional but highly recommended. It cleans as well as

lubricates. Pressure of the spray forces dirt out.

The alternate method is to place 1 drop of approved oil (mineral oil # P-O1) in the chuck hole.

Do not lubricate the handpiece while it is on the Micromotor.

Lubrication of the Straight Handpiece is required at least once a week.

Lubrication by spray lubricant:

1. Make sure that the Straight Handpiece is unlocked prior to lubricating.

2. Install the E-Type nozzle by pushing it onto the top of the spray can. To lubricate and expel debris, insert

the E-Type nozzle into the bottom of the straight handpiece. Holding the two together tightly, with can in the

upright position, push spray button for 2 to 3 seconds.

NOTE: If spray time is too short oil may not be propelled into all areas of the handpiece.

8

P-MM-E 35,000 RPM

Micromotor W/Cord

P-SH-A1:1 Straight

handpiece

P-A1-B Prophy

Angle (Sealed

Bearings)

Snap on rubber cups

Polishing

paste

Loading...

Loading...