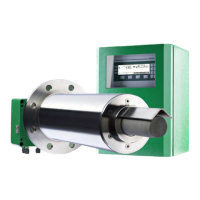

What to do if the O2 display on Enotec COMTEC 6000 ATEX GasEx is higher than expected?

- LLaura BellAug 2, 2025

If the O2 display on your Enotec Measuring Instruments is consistently at the maximum reading or higher than anticipated, check for leaks at the measuring probe or the O sensor flange seal. Ensure all flanges and screw connections are properly tightened. If necessary, replace the O sensor or the O sensor flange seal. If the leak is located around the O sensor, the O2 sensor should be replaced. Also, verify that the probe flange is welded gas tight, and if not, tighten the flange bolts to the correct torque or replace the gasket.