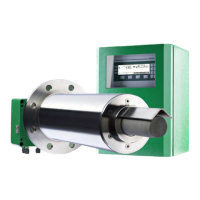

What to do if the O2 display on my Enotec Measuring Instruments remains at the end of the measuring range or is higher than expected?

- MMelissa SchultzAug 2, 2025

If the O2 display remains at the end of the measuring range or is higher than expected, it could be due to leakages at the measuring probe or the O sensor flange seal. Check all flanges and screw connections to ensure they are tight. If there's a leakage around the O sensor, replace the O sensor or the O sensor flange seal. Another cause may be that the probe flange is not welded gas tight, in this case, tighten the flange bolts with the required torque and renew the gasket if necessary.