Service and Maintenance Installation and Operation Manual - COMTEC

®

/

OXITEC

®

DustEx

14 Doc.-ID: COM_OXI_Dust_11022020

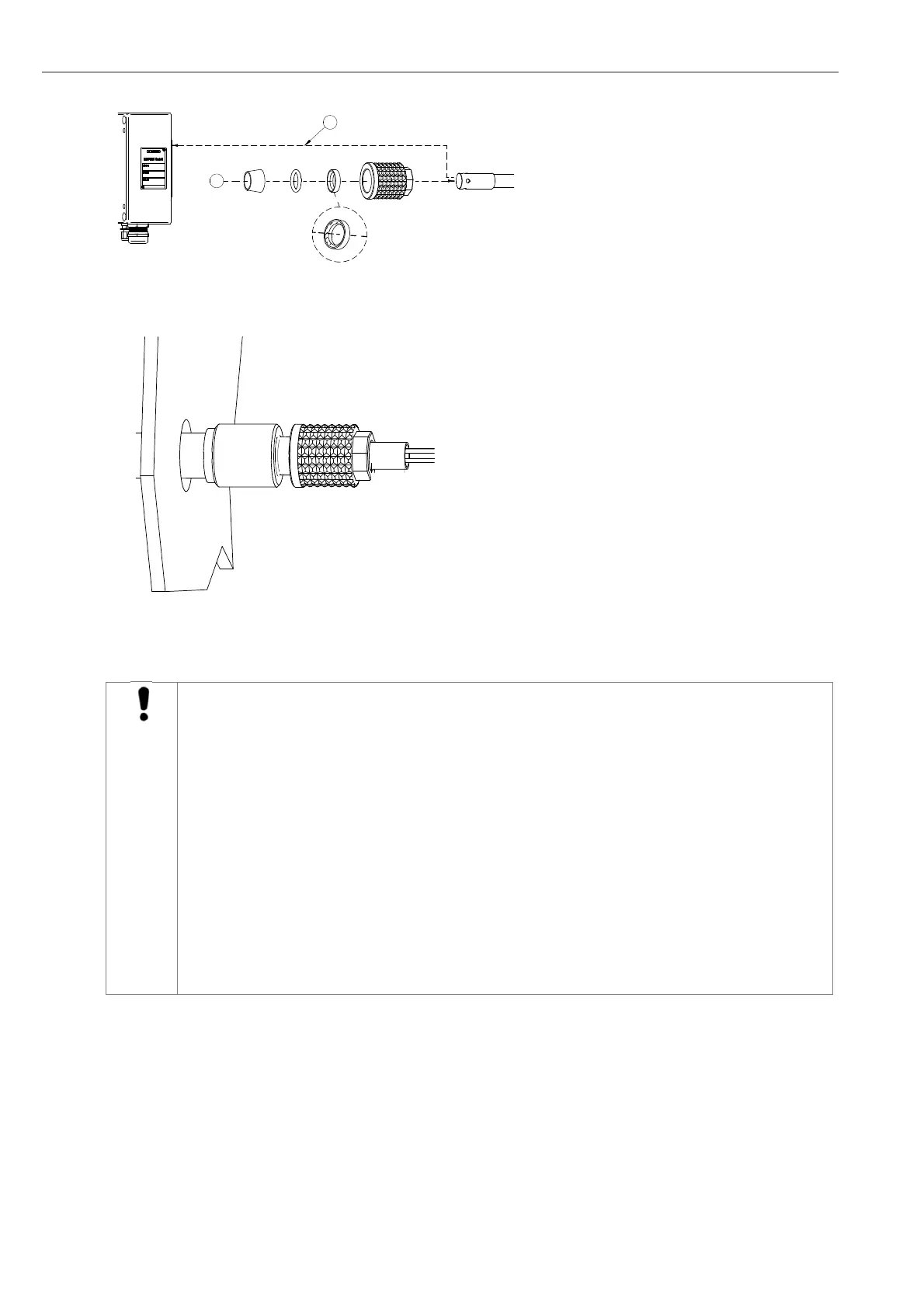

Figure 38 - Prepare the new COe sensor

Prepare the new CO

e

sensor as follows:

Take the clamping ring, the O-ring,

retainer ring and the cap nut and cover

them over the COe sensor.

Note: Mind the position of the bevel. Bevel

must face O-ring!

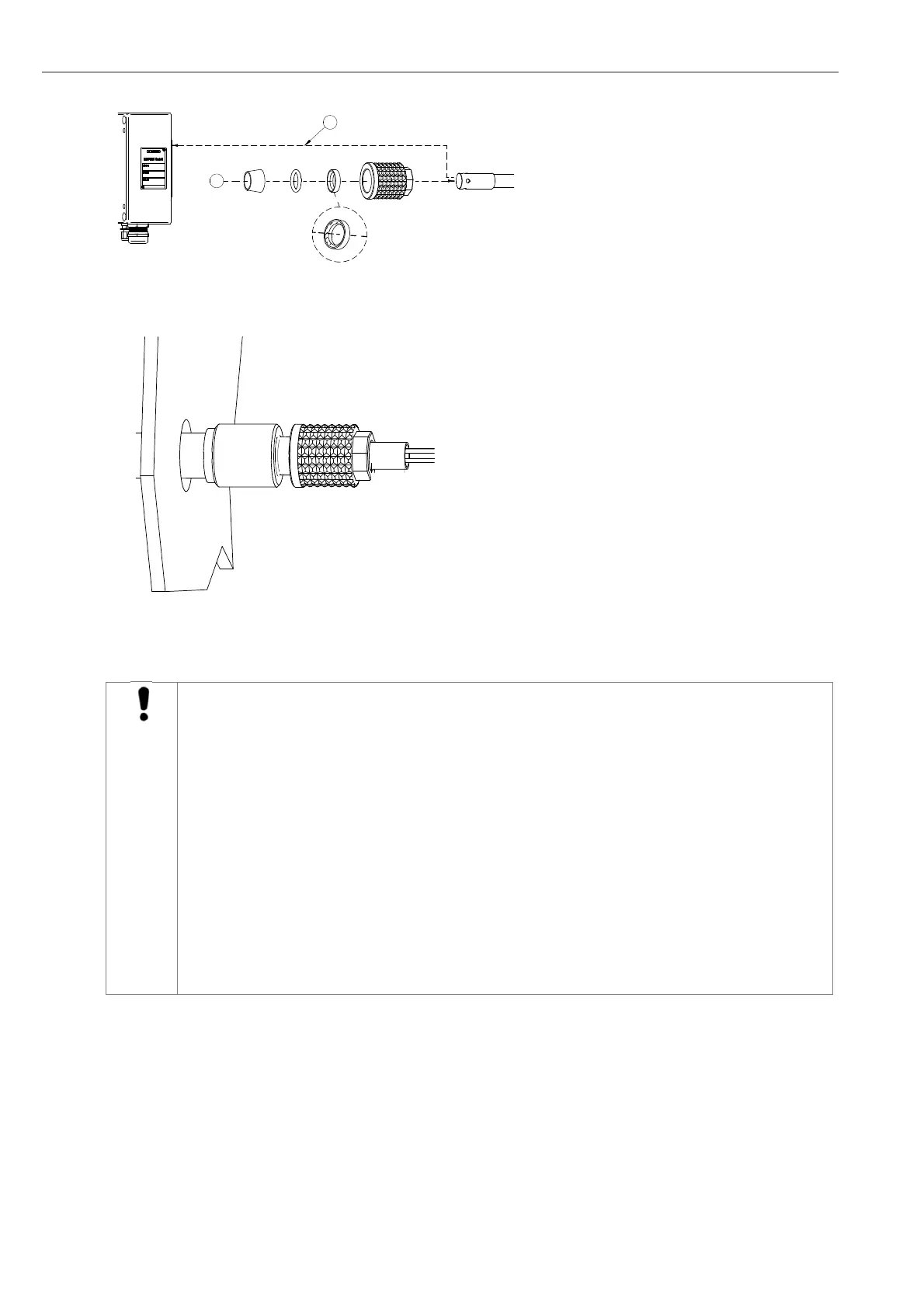

Figure 39 - Insert the new CO

e

sensor

Insert the new CO

e

-sensor into the probe

Tighten the cap nut. Please tighten the

cap nut once more after the system and

the plant are in normal operation for two

hours.

Connect the CO

e

sensor wires at the

terminal block no. 11-14.

Switch on the power supply

Caution

The following parameters have to be entered to ensure correct measurement. Failure to observe this

information

willdestroytheCOesensorimmediately!

The CO

e

sensor must now be activated (via the software) SYS-MENU System Configuration Set

CO

e

measurement ON. After a CO

e

sensor replacement, the following values need to be entered as

specified in the test certificate (see paragraph 4.2.17):

CO

e

RH

0

CO

e

Offset

CO

e

Alpha

CO

e

Beta

CO

e

Gamma

CO

e

Delta

CO

e

SO

2

correction value

If incorrect values have inadvertently been entered, switch the CO

e

measurement off and back on again to repeat

the procedure.

5.10.1 Seal the COe sensor guide tube

In the event of the COe sensor being removed for a prolonged period of time, the COe sensor guide tube must be

sealed to avoid the intake of false air. This must be done with the locking rod and sealing kit for COe sensors

which are delivered with the probe as accessories.

2

1

ca.1

cm

Loading...

Loading...