technical information

installation compliance

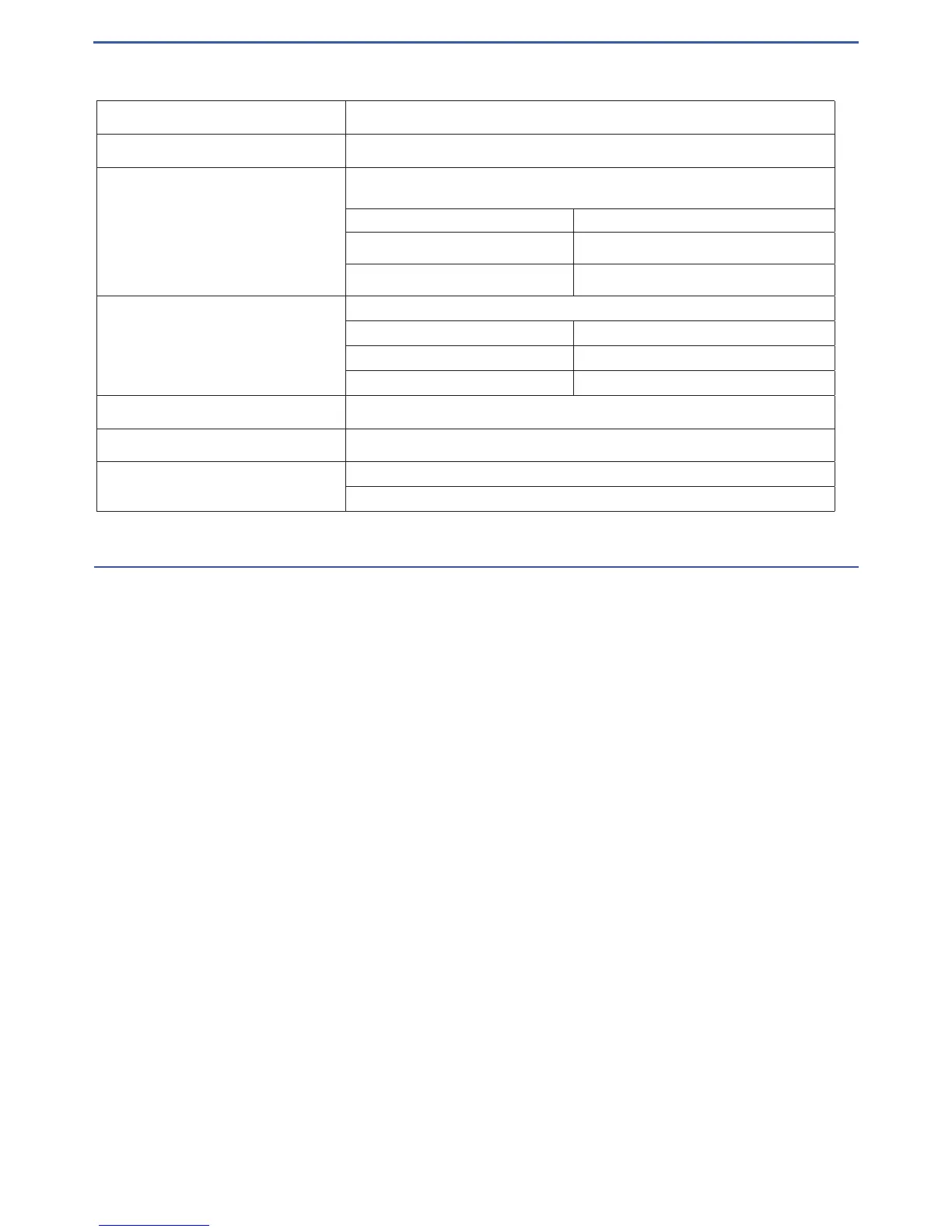

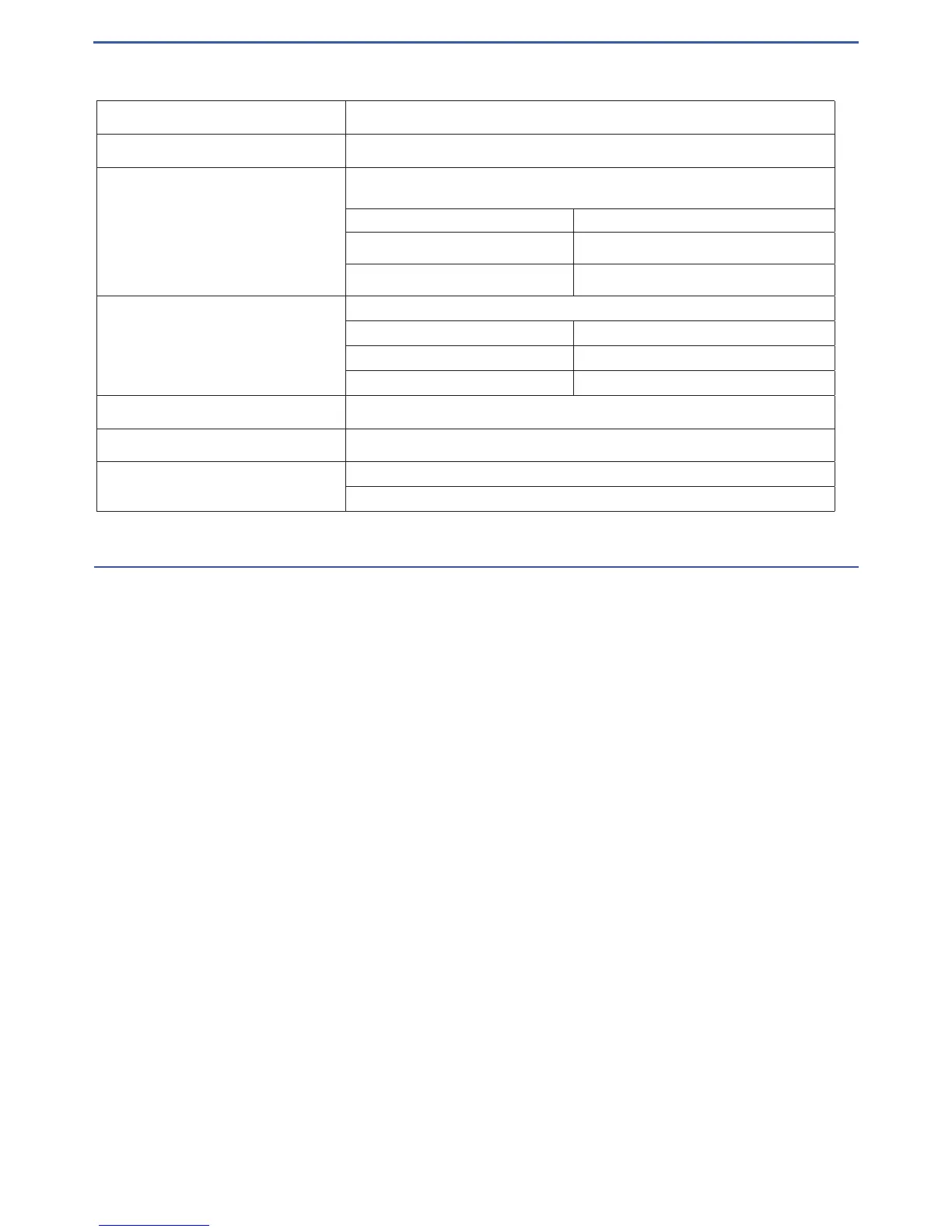

Inlet Connecon 25mm (1” BSP)

Water Supply Line Size Supply piping shall be adequately sized to meet ow requirements

Minimum Requirements to achieve

ANSI Z358.1-2009 and AS/NZS 4775

2007 compliance

Min Working Pressure: 210 kPa (30 psi)

Cauon should be taken when pressure exceeds 550 kPa (80 psi)

Shower Minimum Flow 75.7 lpm (20 US gpm)

Eye Wash Minimum Flow 1.5 lpm (0.4 US gpm)

Eye/Face Wash Minimum Flow 11.4 lpm (3 US gpm)

Enware Performance

At Working Pressure: 210 kPa (30 psi)

Shower Flow 76 lpm (20 US gpm)

Eye Wash Flow 17 lpm (4.5 US gpm)

Eye/Face Wash Flow 26 lpm (6.9 US gpm)

Waste Water Outlet Size 38.1 mm (1½”) OD

Mounng Base Plate Size 150 x 150 mm (5 9/10 “ x 5 9/10”) with 4 bolts 11 mm (7/16”)

Shipping

Approximate Weight: 9.5 - 13.5 kilograms

Dimensions: 1150 x 287.5 x 200 mm

Supply Lines

Installaon procedures shall be in accordance with proper

plumbing pracces. Supply piping shall be adequately sized

to meet ow requirements. If shut o valves are installed

for maintenance purposes, provisions shall be made to

prevent unauthorised shut o.

Placement of Emergency Equipment

Emergency eyewash and shower equipment shall be

available for immediate use. It shall take no longer than

10 seconds for an individual to reach the nearest facility.

Factors that inuence the locaon of emergency facilies

include workplace lighng, obstrucons to the path of

travel and the work environment. It should be noted that

some situaons may warrant the placement of equipment

signicantly closer to the hazard. In these situaons, such

as exposure to highly corrosive chemicals, the proper

distances should be selected based on the advice from

appropriate consultants. For situaons such as exposure to

strong acids or alkalis, due consideraon needs to be given

to possible reacon between the ushing uid and the

chemical if the ushing uid enters a bulk container of the

chemical.

Flushing Fluid Temperature

Connuous and mely irrigaon of aected ssues for

the recommended irrigaon period are the principal factors

in providing rst aid treatment. Providing ushing uid

at temperatures conducive to use for the recommended

irrigaon period is considered an integral part of providing

suitable facilies. Medical recommendaons suggest a

ushing uid at tepid temperature be delivered to aected

chemically-injured ssue. Temperatures in excess of 38ºC

have proven to be harmful to the eyes and can enhance

chemical interacon with the eyes and skin. During design

and installaon, the eects of exposure of pipe to sun,

radiant heat or other heat sources should be considered,

and suitable control measures should be introduced

to avoid any risk of scalding. While cold ushing uid

temperature provide immediate cooling aer chemical

contact, prolonged exposure to cold uids aects the ability

to maintain adequate body temperature and can result

in the premature cessaon of rst aid treatment. Before

emergency eyewash and shower equipment is selected,

a risk assessment shall be carried out to determine the

most appropriate delivery temperature for the applicaon.

Means to ensure a constantly suitable delivery temperature

shall also be idened during selecon, so that equipment

can perform as desired once installed.

Installaon of emergency showers, eye and eye/face wash equipment shall be in accordance with AS/NZS4775-2007

or ANSI Standard Z358.1-2009 - whichever is applicable to the installaon. REFER to checksheet on pages 10 and 11.

Loading...

Loading...