operating and training instructions

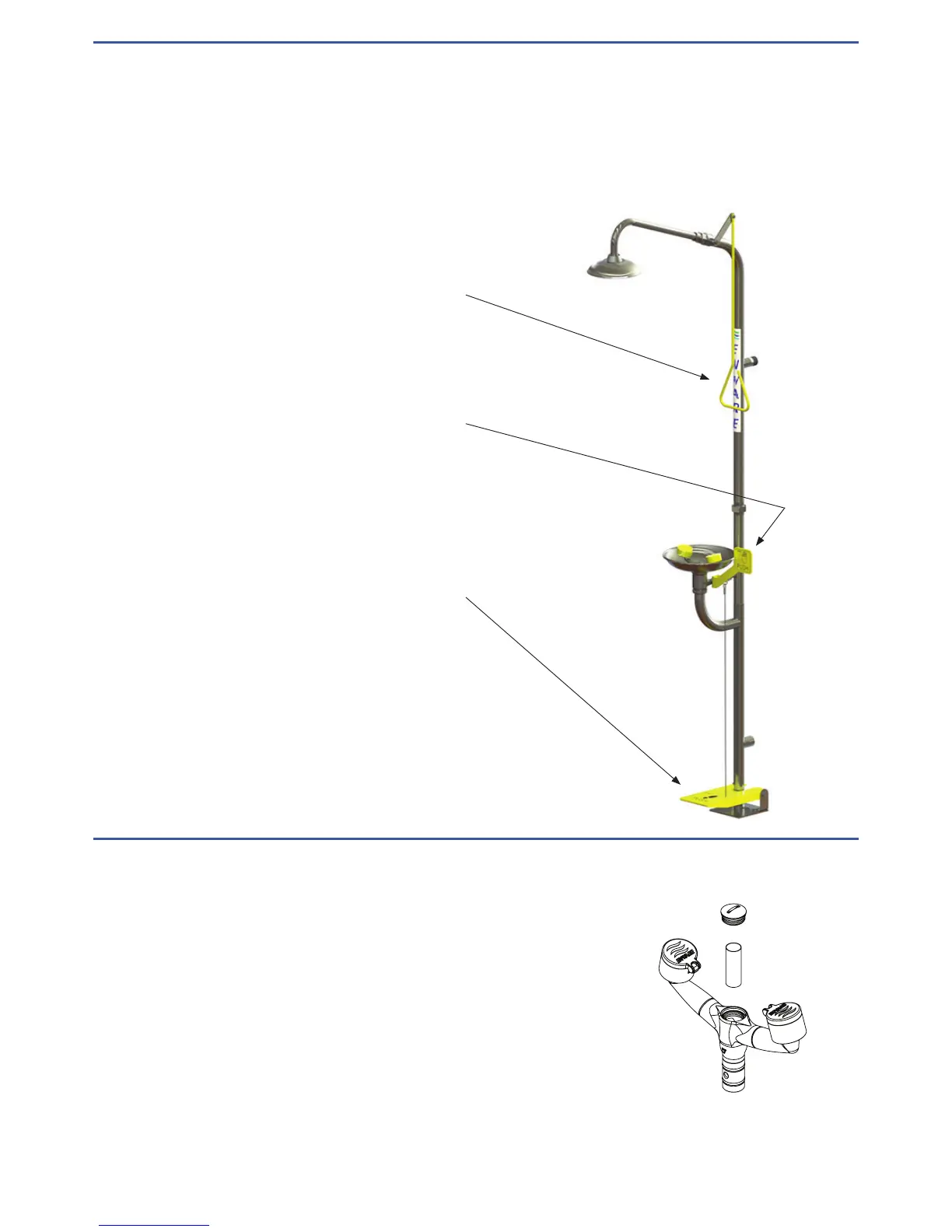

SHOWER OPERATION

Pulling down on the triangular pull handle acvates

the shower; this handle opens the 1’’ ball valve

allowing water to ow through to showerhead. To

close the shower valve and stop ow the handle is

pushed upwards. The water remaining in shower head

will drain through the self-draining hole aer closing

the valve.

EYE, EYE/FACE WASH OPERATION

The Eye/Face wash is acvated by pushing forward

(away from the user) the at “PUSH” handle. This

opens the ½’’ ball valve allowing water to ow to the

Eye, Eye/Face wash outlets. To close the valve and stop

ow, gently pull the handle back up (towards the user).

FOOT PEDAL OPERATION

(ECE090, ENBE090, ECE270, ENBE270)

The Eye, Eye/Face wash can be acvated by pushing

down the foot pedal where marked. This opens the

½’’ ball valve allowing water to ow to the Eye, Eye/

Face wash outlets. To close the valve and stop ow

gently pull the “PUSH” handle back (towards the user).

Releasing the foot pedal will not stop the ow.

Instrucons for all emergency equipment shall be readily accessible to maintenance and training personnel.

Employees who may be exposed to hazardous materials shall be instructed in the locaon and proper use of

emergency shower equipment. Refer to AS/NZS 4775 or ANSI Z358.1 where applicable.

The unit should be acvated every week for a period long enough to

verify operaon and ensure the ushing uid is available. Note: the intent

is to ensure that there is a ushing uid supply at the head of the device

and to clear the supply line of any sediment buildup that could prevent

uid from being delivered to the head of the device and to minimise

microbial contaminaon due to sing water. Internal eye/face wash

strainer should also be removed and cleaned during this process or when

required.

All shower units shall be inspected annually by a qualied technician

to assure conformance with ANSI Z358.1-2009 or AS/NZS 4775- 2007

whichever is applicable to the installaon.

DRAWN

CHECKED

APPROVED

GENERAL NOTES:

- REMOVE ALL BURRS AND SHARP

EDGES UNLESS OTHERWISE STATED

- ALL THREADS TO BE CHAMFERED

- DIMENSIONS ARE IN mm's

- DO NOT SCALE OFF DIMENSIONS

TOLERANCE EXCEPT WHERE STATED:

NO DECIMAL POINT

+

-

0.2

ONE DECIMAL PLACE

+

-

0.1

TWO DECIMAL PLACES

+

-

0.05

ANGLES

+

-

1

FINISH:

SHEET: 1 OF 1

MATERIAL:

TITLE

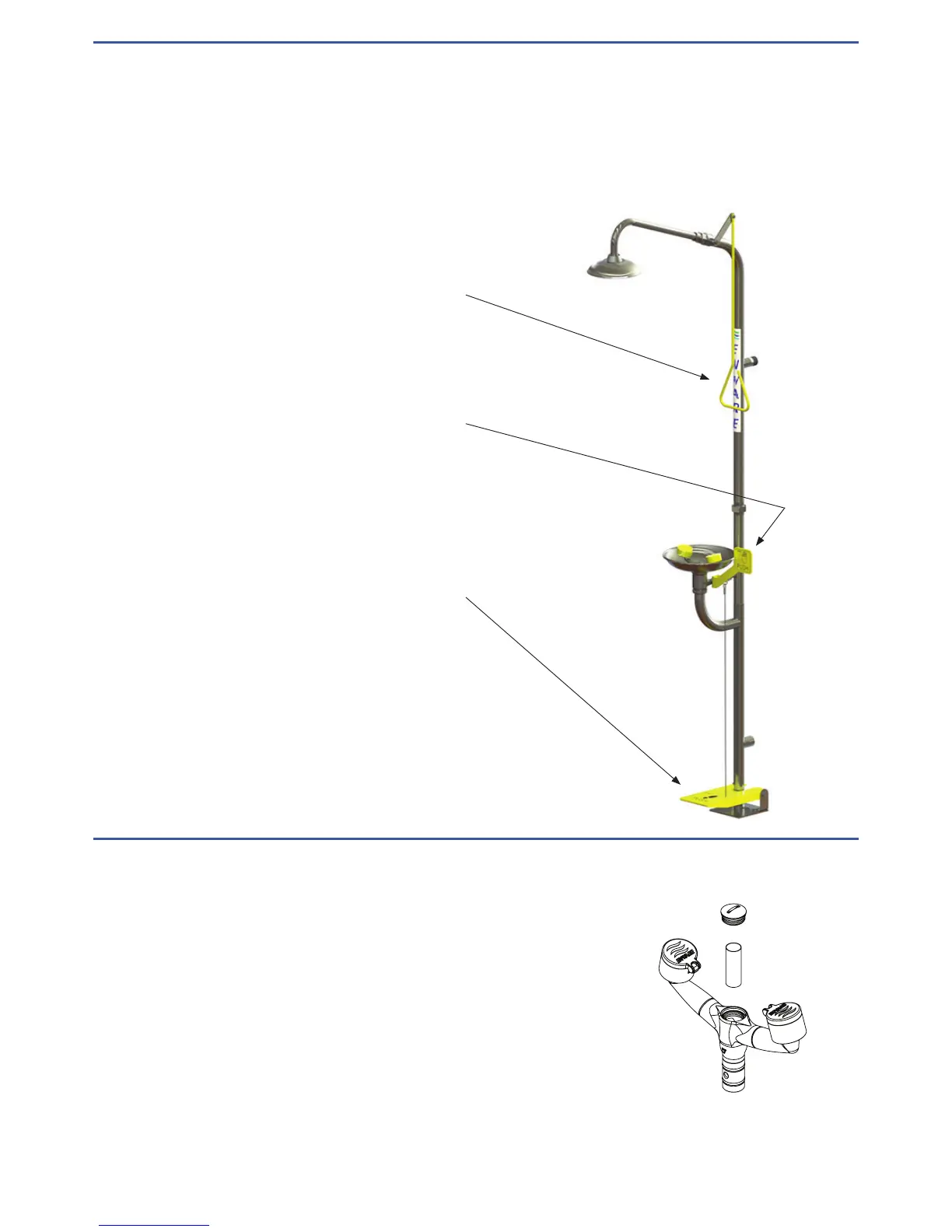

SUB ASS EYEWASH OUTLET ECE

CAST SHOWER

This drawing is the

property of Enware

Australia Pty Ltd and

may not be reproduced

in full or part without the

written consent of

Enware Australia.

9 Endeavour Rd,

Caringbah, NSW, 2229

Ph. 61-2-9525-9511

Fax. 61-2-9524-8421

-

-

AM

A

B

C

D

D

C

B

A

1

2

3

4

4

3

2

1

SIZE: A4

SCALE: 1:2

DRAWING NUMBER

. .

Quality Endorsed

Company

AS/NZS ISO 9001

LIC No. 1213

Standards Australia

Loading...

Loading...