07 08

This chapter enables the user to identify and rectifies basic faults and the effects of incorrect operation.

When trying to locate a fault, proceed in the order shown in the table below. If, after carrying out the

following remedial action listed in “actions”, the truck cannot be restored to operation, contact the

manufacturer’s after-sale service department. Additional troubleshooting must only be performed by the

manufacturer’s specialist service engineers. The manufacturer's customer service department is specially

trained to carry out these operations.

1

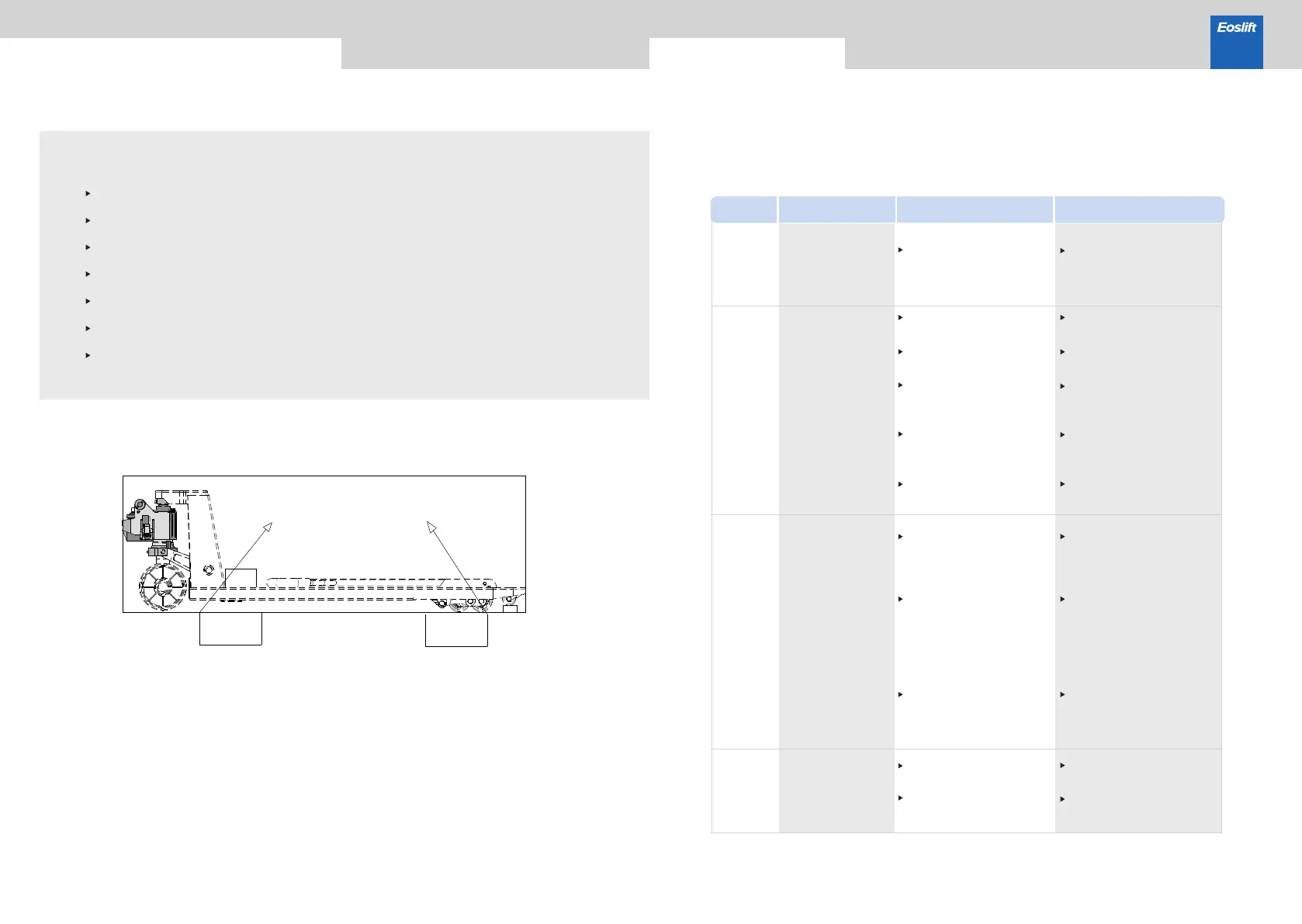

Fault

Possible cause

Action

2

No.

3

4

Troubles shooting

The forks cannot

be lifted to max.

height

The forks cannot

be lifted up

The forks cannot

be lifted down

Oil leakage

The hydraulic oil is

insufficient

Change hydraulic oil

Put the finger grip handle in

the upper position and press

the handle dozens of times

Add the hydraulic oil

Replace the seals

The hydraulic oil has

impurities

Adjusting nut(2-4) or

adjusting screw(2-6) is in

wrong positions

The hydraulic oil is

insufficient

Air enters into the cylinder

Seals damaged

Piston rod or the frame is

deformed resulting from

overloading or cargo

slanting to one side

The forks was kept in raised

position for extended period

of time, then the piston rod

is exposed to the air and gets

rusted , which blocks the

motion of the piston

The adjusting nut(2-4) or

the adjusting screw(2-6) in

wrong positions

Replace the related parts of

the cylinder or the frame with

new ones

Keep the forks at the lowest

position while not in use, and

keep piston rods lubricated in

time

Parts damaged

Seals damaged

Replace the seals

Replace the parts

Adjust the adjusting nut(2-4)

or adjusting screw(2-6) to

correct the position

If the truck have to transporte for a long distance, it should be packed in the wooden pallet in order

to avoid collision during transportation.

Transportion, loading, test and storage

The handle should be fixed stably in case sliding and damages and transported by fork truck

or crane.

Before loading, the operator should first check the truck weight, in order to choose the right

crane.

When unloading the truck, the operator should be aware of safety of the surroundings to ensure

the truck slowly unloaded.

If the truck is transported with the forklift, the forklift shall lift and lower slowly to keep the balance

of the truck.

The truck shall be commissioned according to the following function tests: steering, traveling,

loading control and combined functions with rated capacity.

If the truck doesn’t work, please remove the cargo from the frame and move out the truck from

the working area reasonably.

When the truck won’t be use for a long time, the storage environment shall be kept dry and clean,

with forks lift down to their lowest position.

Add the hydraulic oil

M Series Hand Pallet Trucks

Adjust the adjusting nut(2-4)

or adjusting screw(2-6) to

correct the position

Loading...

Loading...