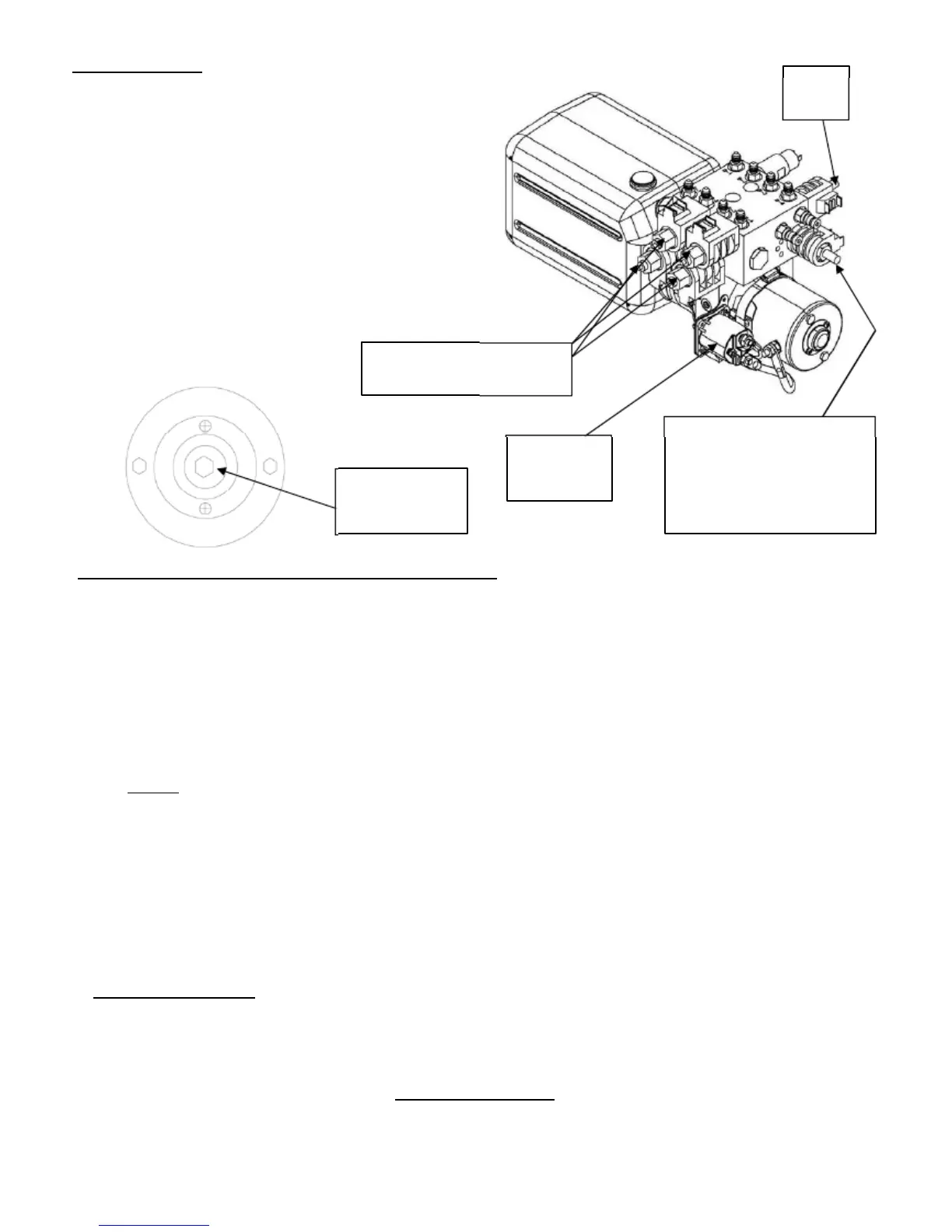

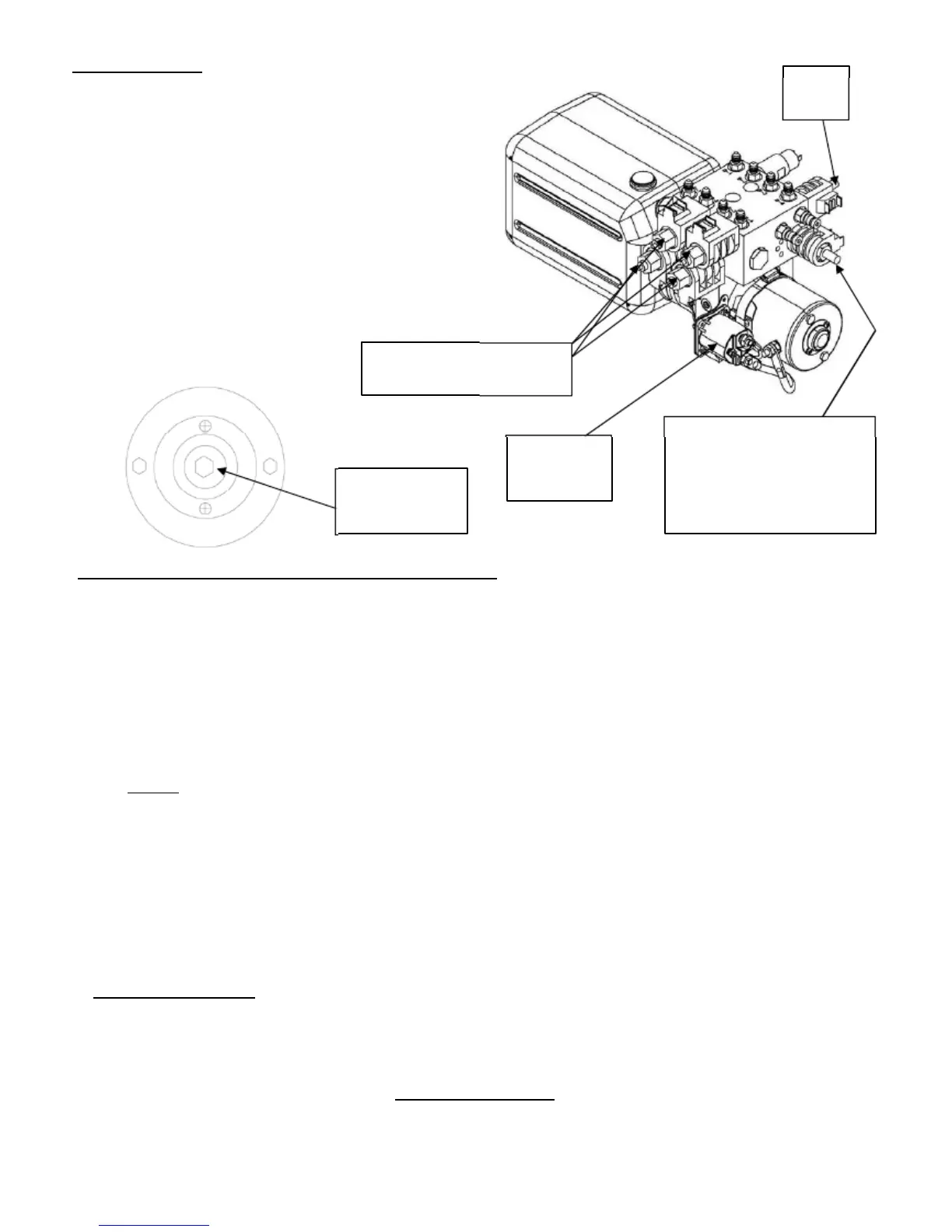

Uni-Directional

DV2

Valve

THIS PUMP IS IDENTIFIED BY A SINGLE MOTOR

SOLENOID AND A SINGLE POWER

POST ON THE MOTOR

The hydraulic pump assembly is equipped with a 7/16” hex

Coupler manual override output shaft.

Use a drill fitted with a 7/16” (11mm) Hex Socket.

The drill must be capable of producing a minimum of

2000 r.p.m. for the pump to develop adequate fluid

output.

Cartridge Valves

(4) shown

DV1 Valve

End of Motor

7/16” Hex

Coupler

Motor

Solenoid

One (1)

Identified by:

•

“DV1” stamped into

manifold

•

Coil wires: (1) Green, (1)

Black

•

Red Knurled Knob

To manually override (uni-directional pump assembly):

1) The individual cartridge valves are clustered together on the side of the pump manifold. Valves for leveling jacks are

labeled 1 thru 4. See the hose connection section in the Operations Manual to identify the valves for slide-out

functions. Locate the screws on the appropriate cartridge valve(s). Using a small flat blade screwdriver or a 1/8” Allen

wrench (depending on which valves you have), turn the

screw(s) clockwise until all the way in and lightly seated. An

individual slide-out room or leveling jack can be

manually overridden by only opening the valve associated with that

function.

2) Locate the DV2 Valve: This valve will be on the opposite side of the manifold from the cluster of cartridge valves.

Pull the red knob out and turn 1/4 turn by hand, or (depending on which valve you have) use a 1/8” Allen wrench and

turn the screw clockwise until seated. The valve will remain in the ‘out’ position.

3) To

retract, locate the red knurled knob on the directional valve: DV1 valve. This valve will be on the motor

side of the manifold. Pull the red knob out and turn 1/4 turn by hand. The knob will remain in the ‘out’ position.

Some pump assemblies may have an Allen screw, turn in (clockwise) till seated.

4) Remove the black plastic cap from the end of the motor. Use a small flat head screwdriver. Place the drill with

the 7/16” (1 1mm) hex bit on the manual override shaft located at the top of the motor. Run drill in a clockwise

direction at 2000 r.p.m. (minimum). The jack leg(s) will retract. Care must be taken to ensure the drill or socket does

not contact any wires or hoses.

5) When retraction is complete, return the cartridge valve(s) and the directional valves DV1 & DV2 to the

normal positions. Reinstall black plastic cap on motor.

To extend your jacks: Follow all of the above steps except DO NOT manually shift directional valve DV1 as

described in step #3 above.

►!!!!!!!◄

Following manual override operation, return all valves to normal operational position. Failure to do so may result in drifting from

the

retracted (stowed) position of slide-outs or leveling jacks.

Cartridge valves: Rotate the center screw fully counter-clockwise until lightly seated.

DV2: (Depending on which valve you have) Turn the red knob and allow the valve handle to snap IN or Closed. Operate

this style valve by hand only- NO TOOLS! Or, DV2 may be turned counter-clockwise with a 1/8

”

Allen wrench.

8

Loading...

Loading...