TROUBLESHOOTING

Caution: Troubleshooting could lead to an increased risk to the operator due

to the fact that safety guards / covers may have to be removed. It is therefore

particularly important that all the measures necessary for safe working are taken.

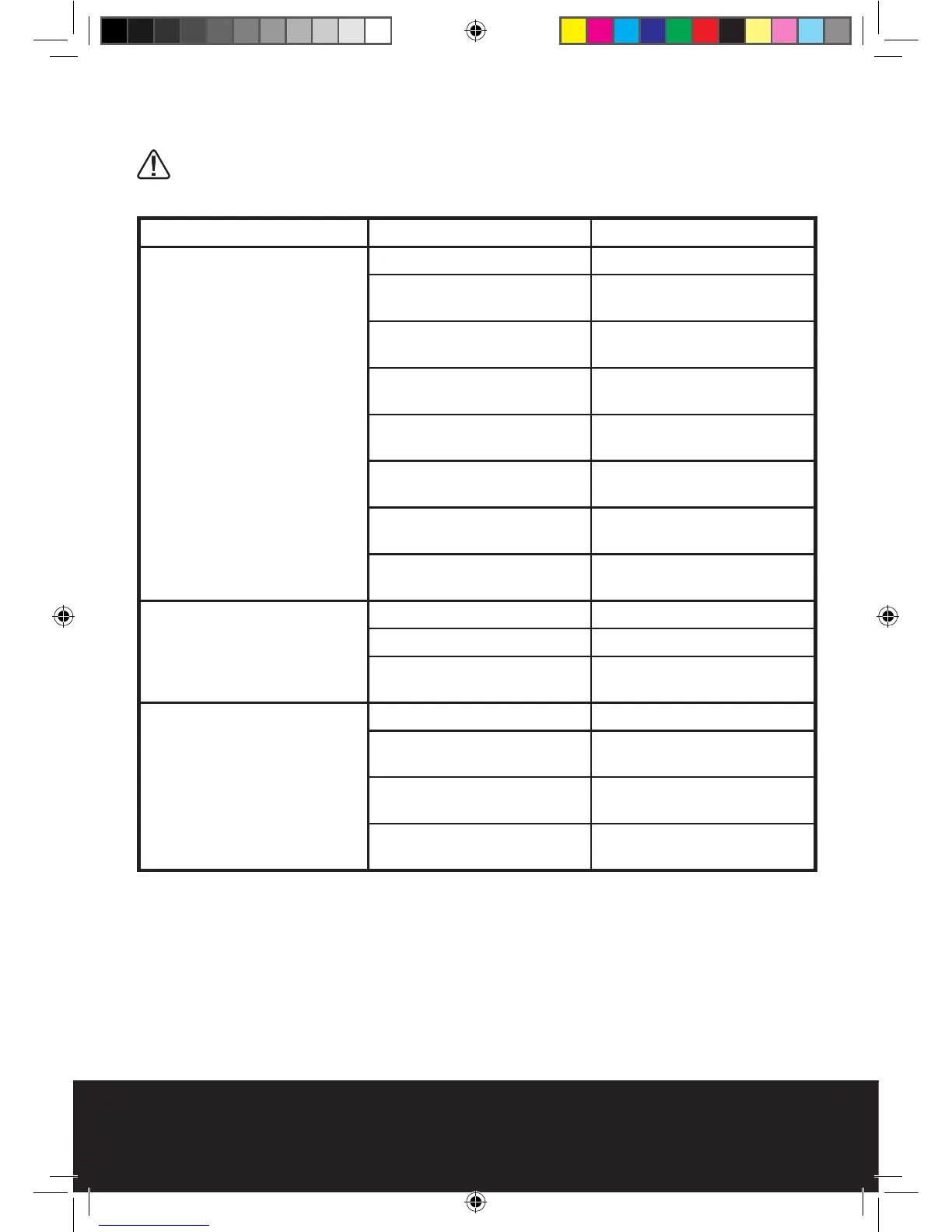

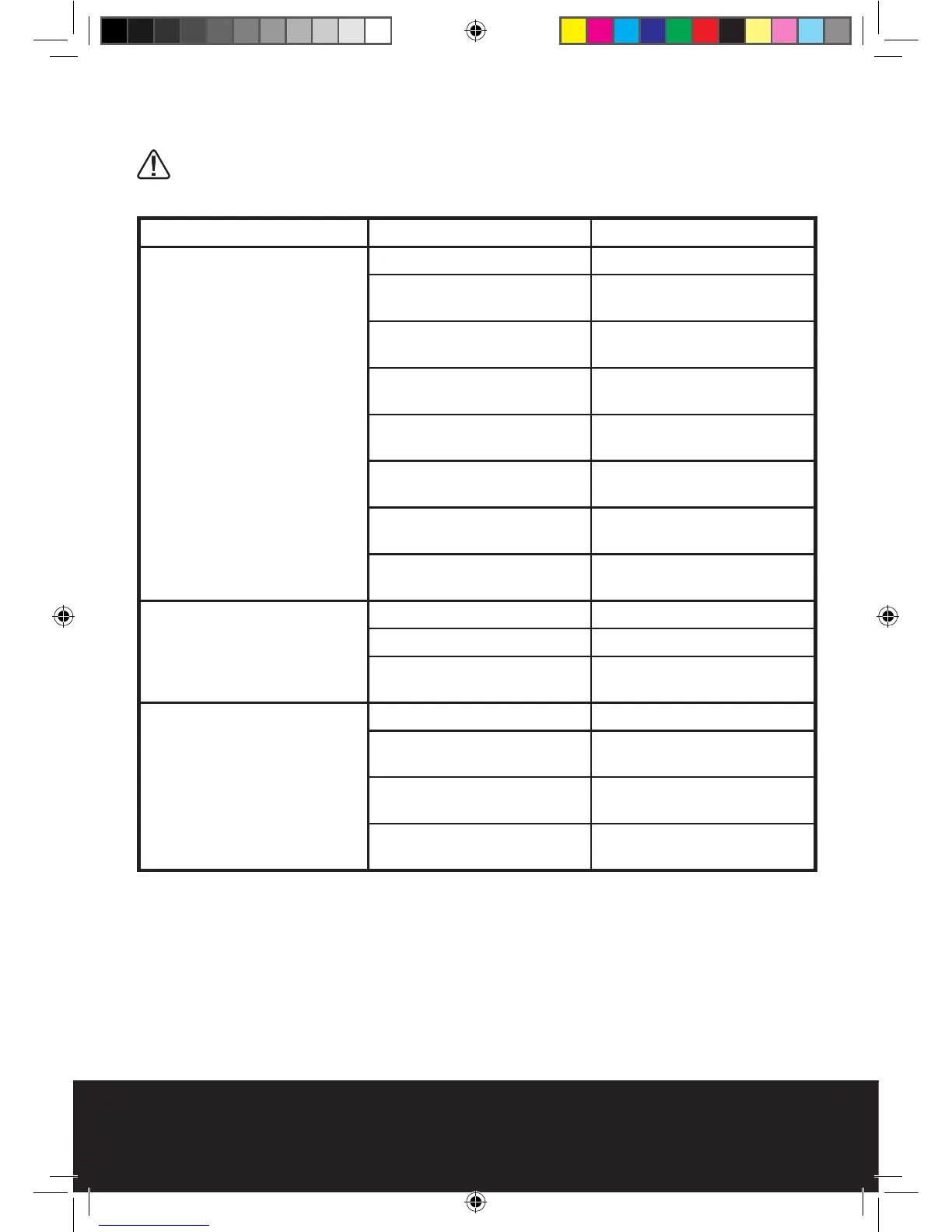

Fault Possible causes Possible solutions

Machine will not run No mains voltage. Check the supply.

Fuse blown. Check the fuse and replace

if necessary.

Overload switch has cut

in.

Allow the machine to cool

and reset the switch.

Faulty NVR switch. Check and replace if

necessary.

Carbon brushes worn. Check and replace if

necessary.

Faulty motor. Check and replace if

necessary.

Damaged mains lead. Check and replace if

necessary.

Safety interlock switch is

not correctly engaged

Check that the extraction

port is correctly seated.

Speed drops whilst the

machine is under load.

Cutting depth is too great. Reduce the cutting depth.

Feed rate is too fast. Reduce the feed rate.

Dull cutter blades. Replace / sharpen the

cutter blades.

The motor cuts out whilst

under no load.

Mains failure. Check the supply.

Motor has exceeded its

duty cycle.

Allow the motor to cool

and reset the overload.

Faulty motor. Check and replace if

necessary.

Faulty NVR switch. Check and replace if

necessary.

Loading...

Loading...