26

KAPITTEL 4 BRUK

1. Tilkople nettstrøm ved å sette den eksterne skillebryteren til PÅ. (EPP-400 har ingen

AV/PÅ-bryter). Nettspenningsindikatoren MAIN POWER vil lyse, og feilindikatoren

FAULT vil blunke for deretter å slukke.

2. Velg innstilling for venderen PANEL/REMOTE.

3. Still inn venderen PILOT ARC HIGH/LOW. Hvis Pilot arc High / Low velges fra en

ernkontroll, må bryteren være i lav-stilling. (Se skjæredata i brennerhåndboken).

4. I PANEL-modus, se på forhåndsinnstilt strøm ved hjelp av ACTUAL AMPS / PRESET

AMPS-venderen (ACTUAL=virkelig, PRESET=forhåndsinnstilt). Juster strømmen inntil

omtrentlig ønsket verdi vises av amperemeteret. I ernstyringsmodus, hvis ACTUAL

AMPS / PRESET AMPS-venderen er satt til PRESET AMPS, vises utgangsstrømmen

ernkontrollen vil begynne med.

5. Start plasmaskjæreoperasjonen. Dette kan inkludere andre manuelle

forhåndsinnstillinger, avhengig av den totale plasmapakken.

6. I PANEL-modus, etter at skjæringen har begynt, juster strømmen til ønsket verdi.

7. Hvis skjæring eller avmerking ikke vil starte opp, sjekk om feilindikatoren FAULT

lyser. Hvis den lyser, se feilsøkingskapitlet.

Merknad:

Feilindikatoren FAULT blinker når kontaktoren skrus på første gang, noe

som betyr at likestrømsbussen starter opp på normal måte.

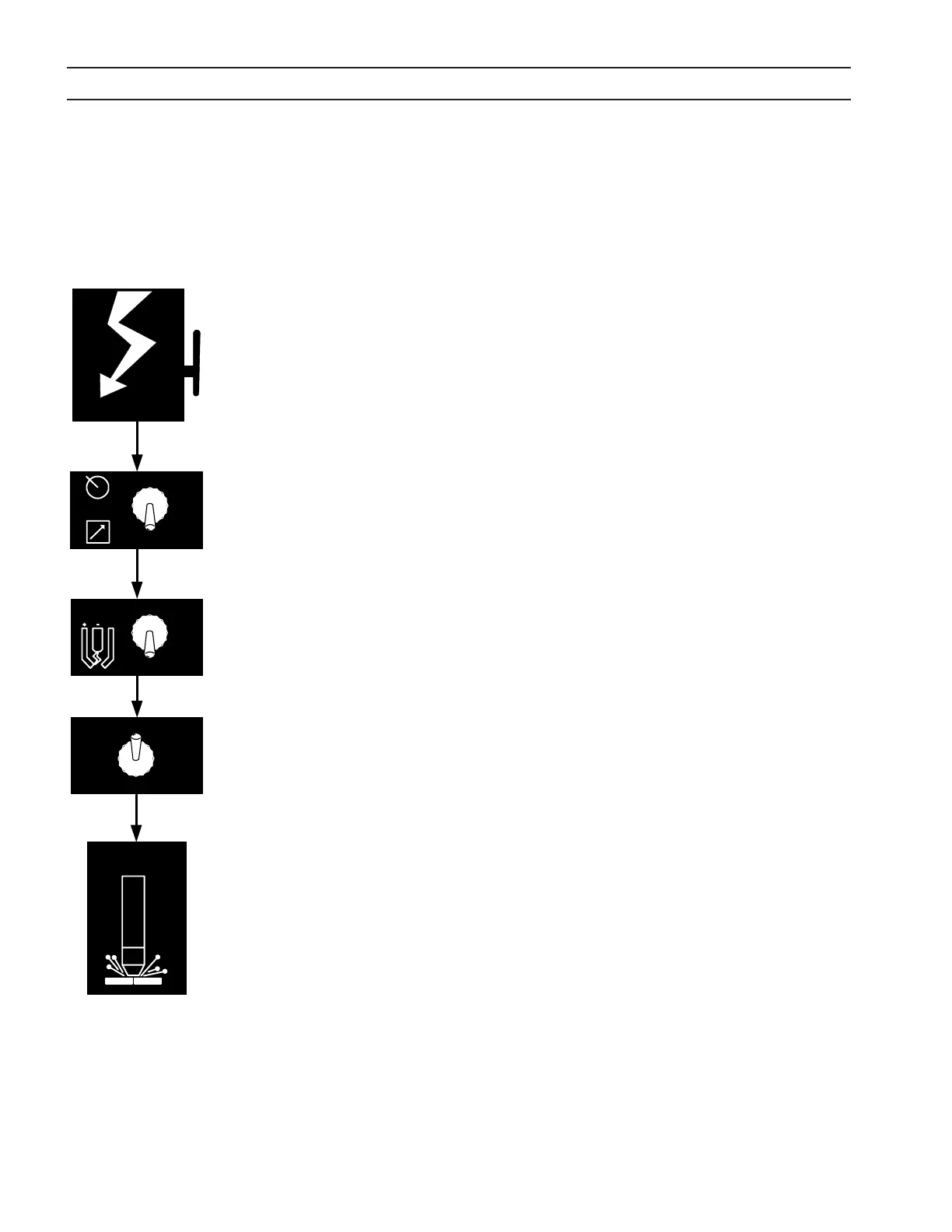

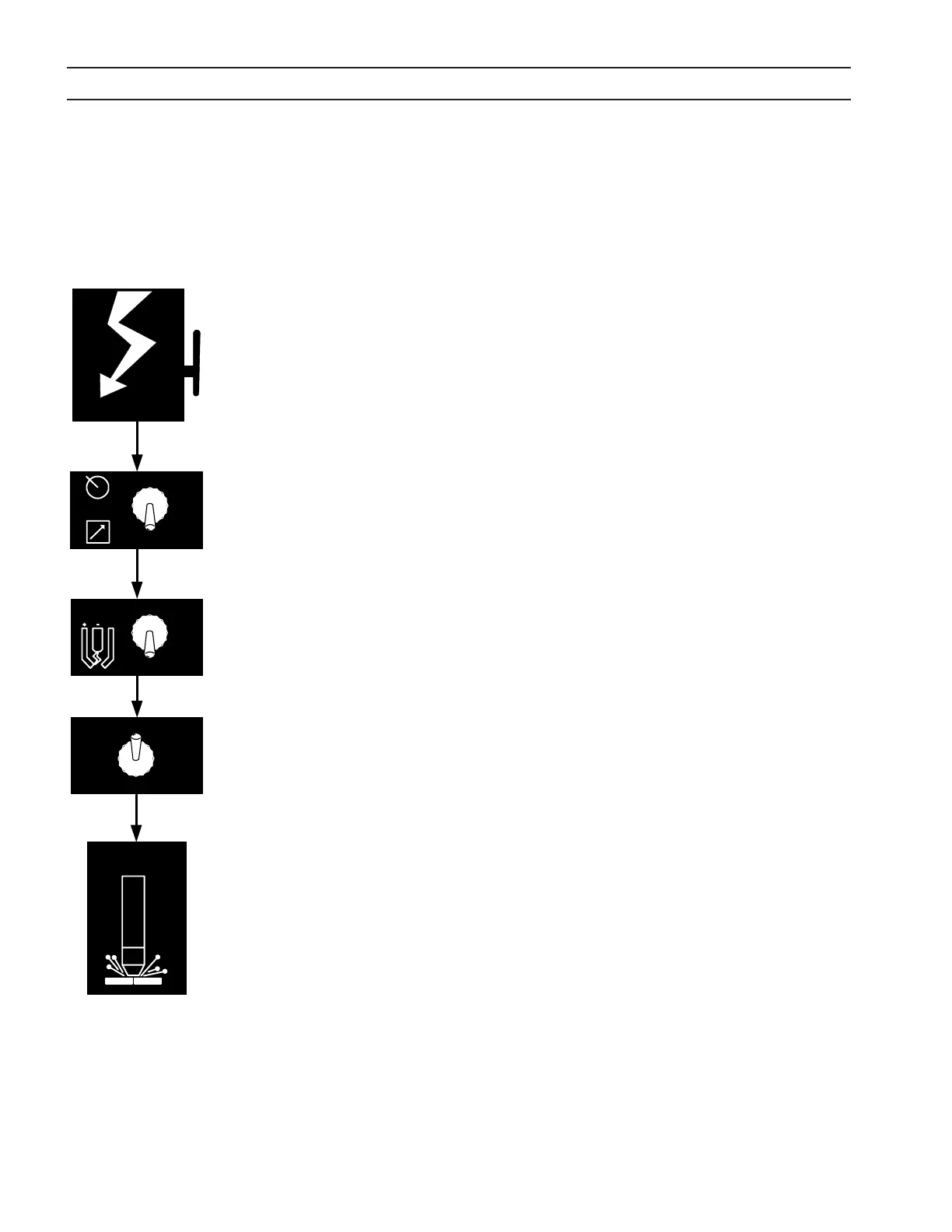

4.3 Funksjonsrekkefølge

SECTION 4 Operation

ESP 400C Plasma Power Source

ESP 400C Plasma Power SourceESP 400C Plasma Power Source

ESP 400C Plasma Power Source

4-4

Begin

Cutting

ACTUAL AMPS

PRESET AMPS

HIGH

LOW

PILOT

ARC

PANEL

REMOTE

Apply Power

4.3 Sequence of Operation

1. Apply power by closing the line (wall) switch.

(The ESP-400C does not have an on/off

switch). The main power light will illuminate

and the fault light will flash and then go out.

2. Select the Panel/Remote setting.

3. Set pilot arc High/Low switch. (Refer to cutting

data in the torch manual.)

4. If using panel mode, view preset amps with the

ACTUAL/PRESET AMPS switch. Adjust current

until the approximate desired value is shown on

the ammeter.

5. Begin plasma cutting operation. This may

include manually setting up other options,

depending on the total plasma package.

6. If using panel mode, after cutting has begun,

adjust current to desired amount.

7. Check for fault light. If a fault light illuminates,

refer to troubleshooting section.

Note: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor isNote: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor is

first turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered upfirst turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered up

normally.

normally.normally.

normally.

4.4 Arc Initiation Settings

The time to achieve full current can be adjusted to

suit your particular system. This feature uses 50%

of the cutting current to start, dwell and then

gradually (less than a second) achieve full current.

The ESP-400C is factory shipped with this feature

enabled. The default settings are:

Minimum Start Current 40A

Start Current 50% of cut current

Timing to achieve full current 800 msec

Dwell Time 50 msec

Loading...

Loading...