39

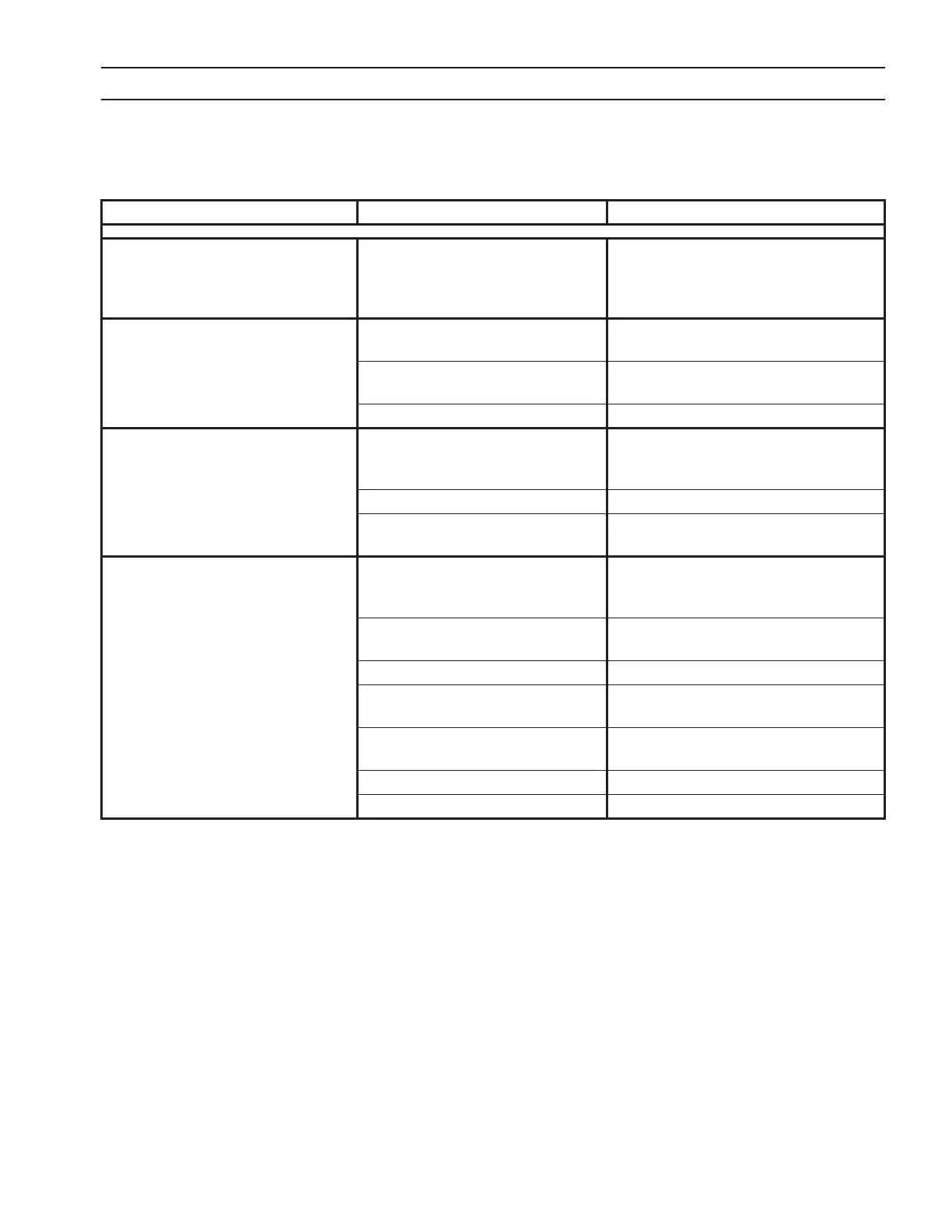

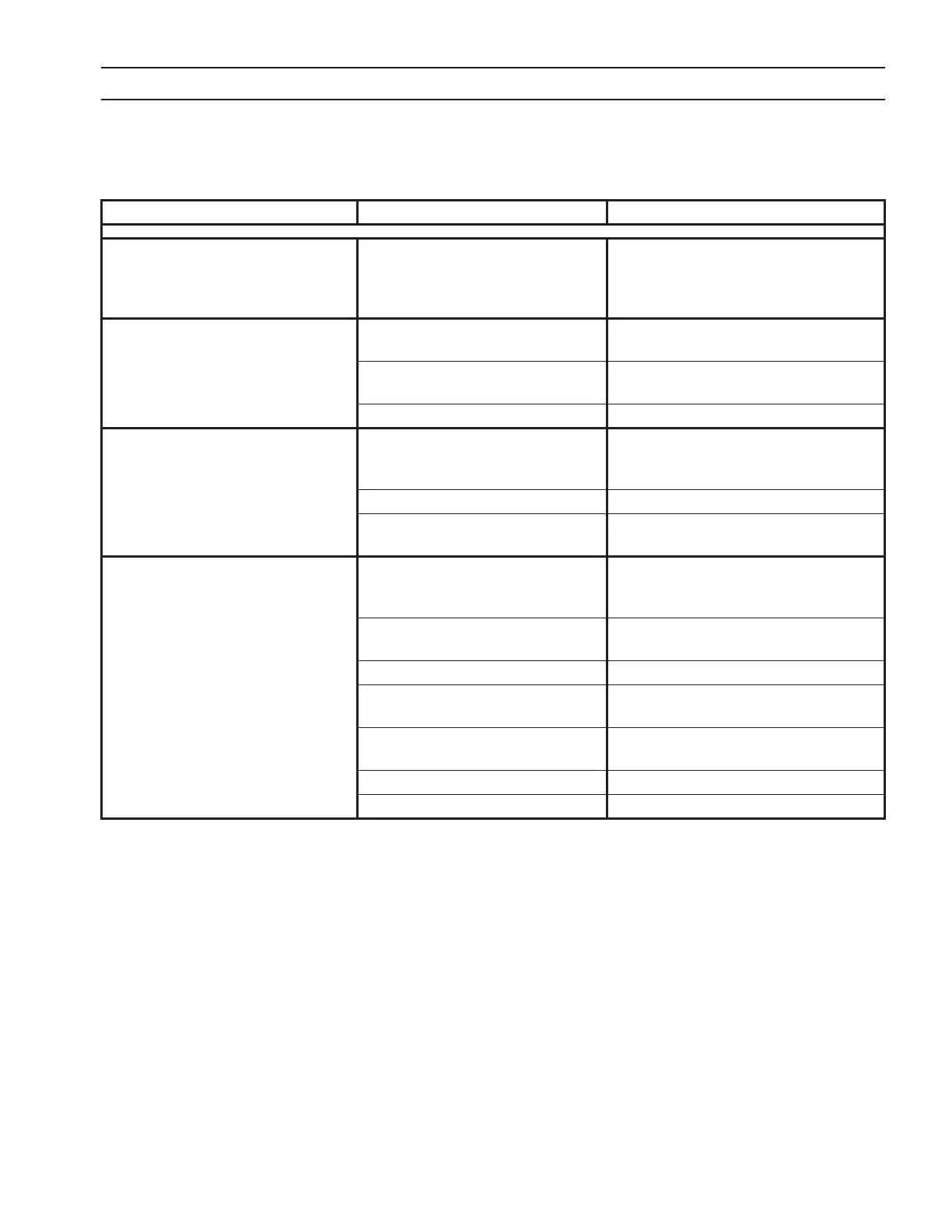

Problem Possible Cause Action

Fault light illuminates at the end of

cut but goes o at the start of the

next.

Normal condition caused when ter-

minating the arc by running the torch

o the work or the arc being attached

to a part that falls away.

Reprogram cutting process to

ensure arc is terminated only by

removing the “Contactor On” signal.

LED 3 – (amber) Bus Ripple

Imbalance of 3-phase input power

Maintain phase voltage imbalance

of less than 5%.

Momentary loss of one phase of

input power

Restore and maintain input power

within ±10% nominal

Faulty control PCB1 Replace PCB1 P/N

0558038287

LED 4 – (amber) High Bus

One or more phases of input voltage

exceed nominal line voltage by more

than 15%.

Restore and maintain line voltage

within ±10%

Faulty control PCB1 Replace PCB1 P/N

0558038287

One or more shorted diode rectiers

(D25-D28) on the “Electrode Plate”

Replace shorted diode rectiers

LED 5 – (amber) Low Bus

One or more phases of input volt-

age are lower than nominal by more

than 15%.

Restore and maintain within

±10% of nominal

Blown F1 and F2 fuses

See F1 and F2 in Blown

Fuses Section

Over temp Light comes on. See over temp in Fault Light Section

Imbalanced 3-phase input

power

Maintain phase voltage imbalance

of less than 5%

Momentary loss of one phase of

input power

Restore and maintain within

±10% of nominal

Faulty Main Contactor (K1) Replace K1

FAULTY Control PCB1 Replace PCB1 P/N

0558038287

SECTION 6 TROUBLESHOOTING

6.3.3 Fault Light Illumination

Loading...

Loading...