ASSEMBLY INSTRUCTIONS (Day 3)

9.

3

2

IMPORTANT! BE SURE CONCRETE HAS BEEN

ALLOWED TO CURE FOR AT LEAST 2 DAYS.

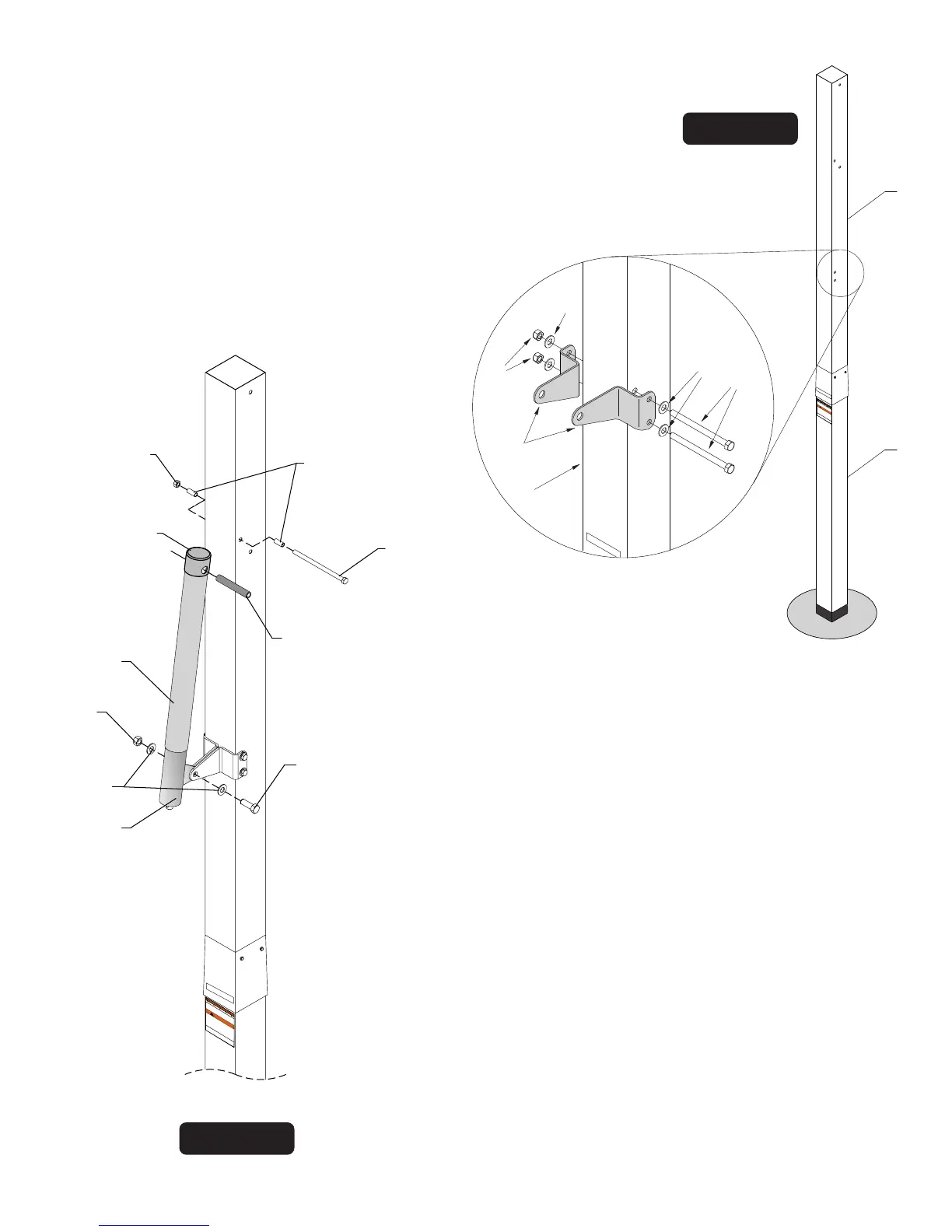

Figure 7

10.

11.

12.

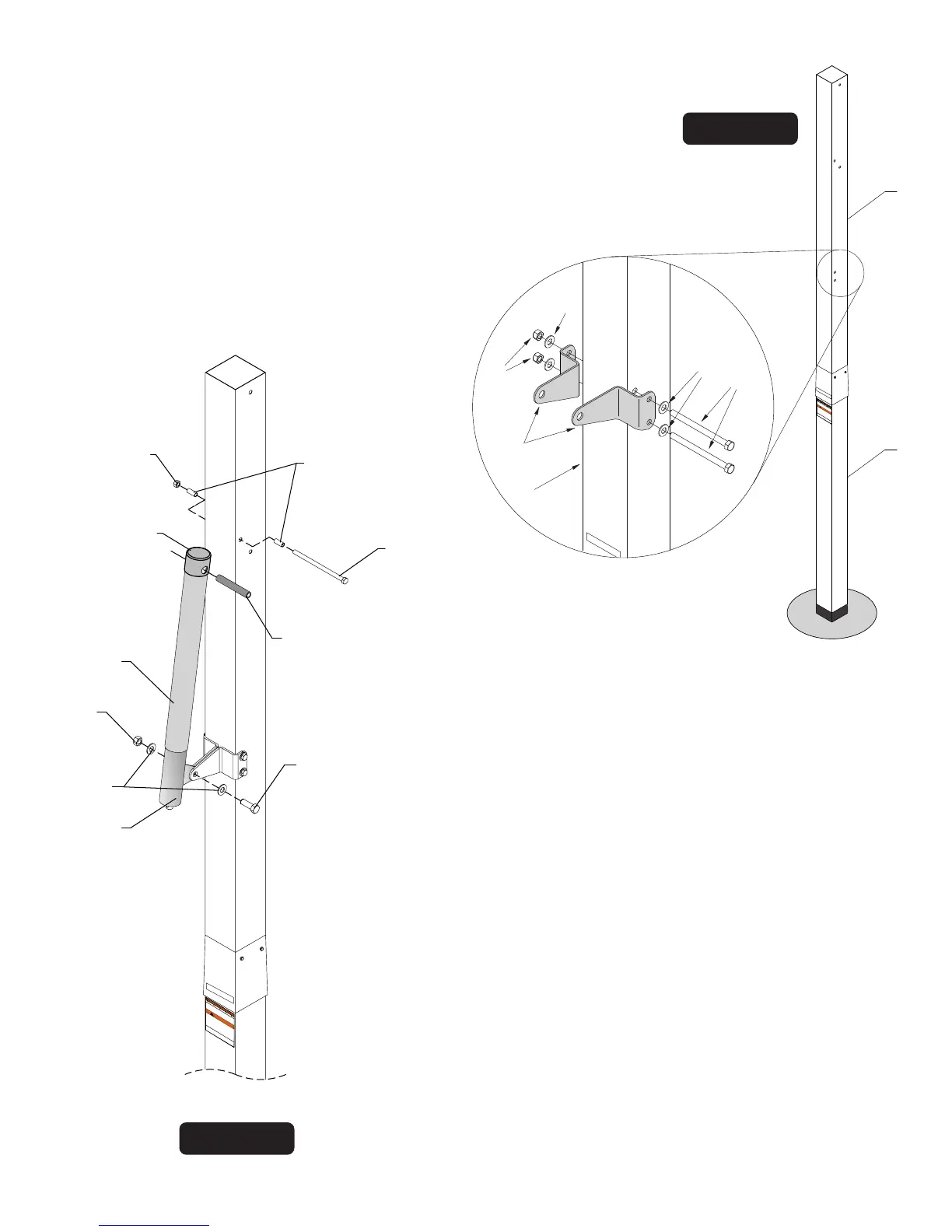

Figure 8

Detail 2

Note: If necessary, use a rubber mallet to tap in

Pivot Tube (#14)

If not already pre-assembled, slide Plastic Actuator Sleeve

(#15) over Steel Actuator (#16) and place Actuator Cap

(#13) on top. Align holes in all 3 parts and slide Pivot Tube

(#14) through holes in Actuator Cap (#13), Plastic Actuator

Sleeve (#15) and Steel Actuator (#16) until equal amounts

stick out through both sides of actuator. See Figure 8.

7

10

4

14

15

16

19

20

21

13

FAILURE TO FULLY ENGAGE THE

BOTTOM OF THE UPPER POLE TO

THE 6” MARK ON THIS BOTTOM

POLE STICKER, COULD CAUSE

YOUR UNIT TO COLLAPSE AND MAY

RESULT IN SERIOUS INJURY OR

PROPERTY DAMAGE.

BACKSIDE

Bottom of upper

pole

must cover

the

above

orange portion of

this sticker

(6” mark).

W

ARNING

!

4L-8151-00

BACK SIDE

FAILURE TO FULLY ENGAGE THE

BOTTOM OF THE UPPER POLE TO

THE 6” MARK ON THIS BOTTOM

POLE STICKER, COULD CAUSE

YOUR UNIT TO COLLAPSE AND MAY

RESUL

T IN SERIOUS INJURY OR

PROPERTY DAMAGE.

BACKSIDE

Bottom of

upper pole

must cover

the

above

orange

portion of

this

sticker

(6” mark).

WARNING

!

4L-8151-00

BACK SIDE

10

Attach Post Ears (#30) to holes near the bottom of the Top Post (#3) using two

hex bolts (#25) four washers (#18) and two lock nuts (#4). Do not tighten

nuts (#4) completely until instructed to do so. See Figure 7 & Detail 2.

BACK SIDE

18

18

25

4

30

3

NOTE: Make sure (#14) Pivot Tube is

installed through all three parts:

1. Actuator Cap (#13)

2. Plastic Sleeve (#15)

3. Steel Actuator Tube (#16)

(#7) Bolt goes in

upper hole

Slide tab on Actuator (#16) between Post Ears #30 and

secure using one Bolt (#19), two Washers (#20) and one

Lock Nut (#21). Tighten Lock Nut (#21) snug but DO NOT

over tighten. See Figure 8. At this time also tighten nuts

(#4) from Step 9.

Secure two Stop Spacers (#10) to pole, as shown in Figure 8,

using one Hex Head Bolt (#7) and one Lock Nut (#4).

Tighten Lock Nut (#4) but DO NOT over tighten.

Loading...

Loading...