What to do if my Everlast Cutter air flows but the arc does not start within 2-3 seconds?

- RRoger SullivanSep 9, 2025

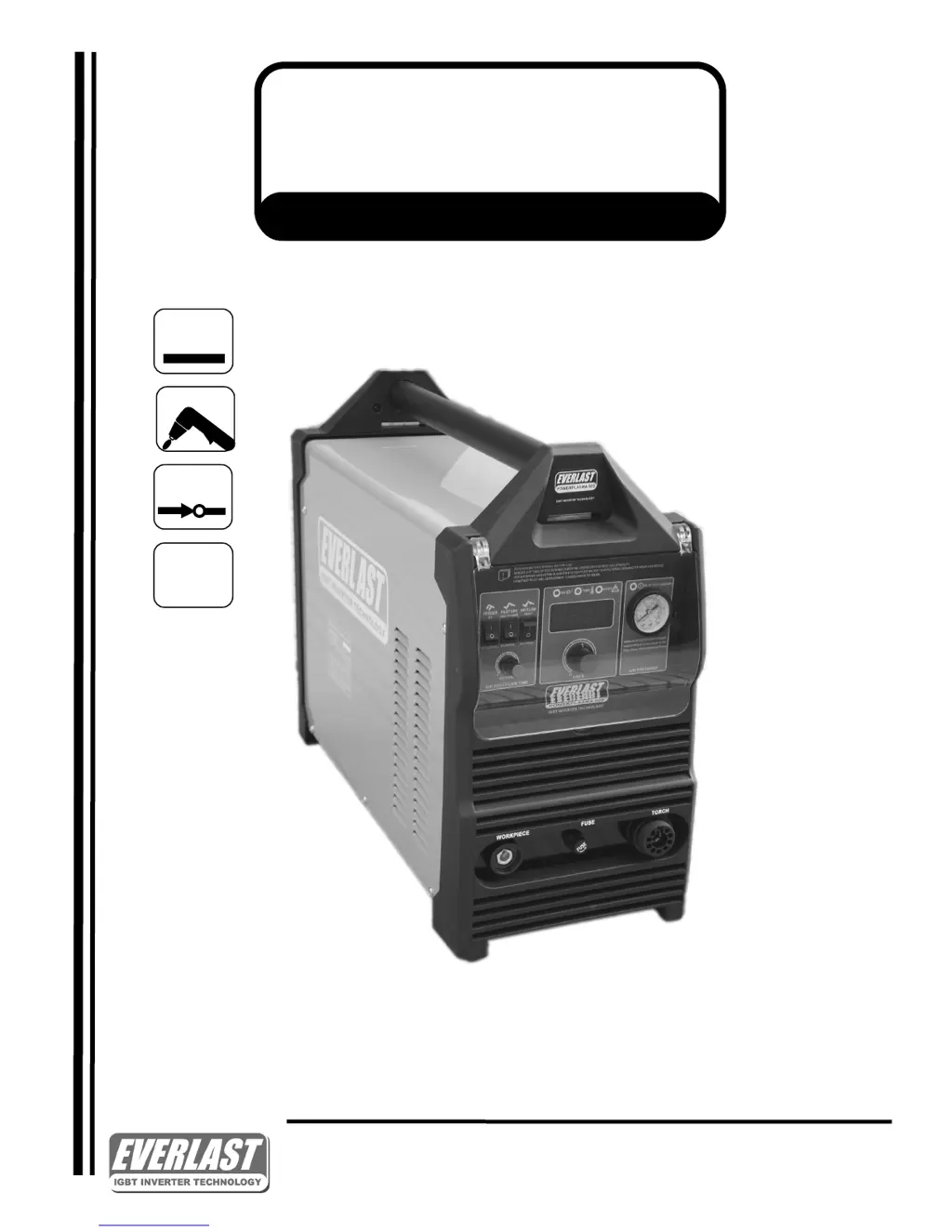

Check the consumables for wear and tightness. Also, check the fuse and air pressure. Ensure the spring/piston on the torch blow back mechanism isn't sticky or slow. You can also release the trigger and try again.