34

Using The Evinrude MFE Outboard

Engine De-Water

The MFE outboard is NOT a submersible en-

gine. However, due to the extreme operating

con

ditions this engine may experience, a

crankcase drain system has been provided to

de-water the engine should water intrusion

occur during deployment or accidental roll-

over.

This system allows the operator to quickly re-

move water and re-start the engine in an

emerg

ency situation. In most cases the en-

gine can be returned to normal operation with-

out damage.

Avoid submersion of the o

utboard. Damage

could occur to the engine wiring harness and

water could contaminate the oiling system.

Extended submersion, particularly in salt wa-

ter, could result in corrosi

on of internal com-

ponents such as piston rings, cylinder

sle

eves, and bearings.

After submersion, all boat and engine electri-

cal, fuel, and oiling systems must be

inspect-

ed for signs of water intrusion. A qualified

technician should

perform this service.

Once an outboard has been under water

(fresh or salt water), it M

UST be serviced

and started within three (3) hours of recov-

ery. Immedi

ate service can minimize the cor-

rosive effect that air has on the polished

surfaces of the

crankshaft, connecting rods,

and internal powerhead bearings.

IMPORTANT: If the outboard cannot be start-

ed or serviced immediately, it should be re-

submerged in fresh water to avoid exposure

to the atmosphere.

De-Water Procedure

CAUTION

NOTICE

1) Place shift lever in NEUTRAL and remove

the engine cut–off switch clip and tether

cord.

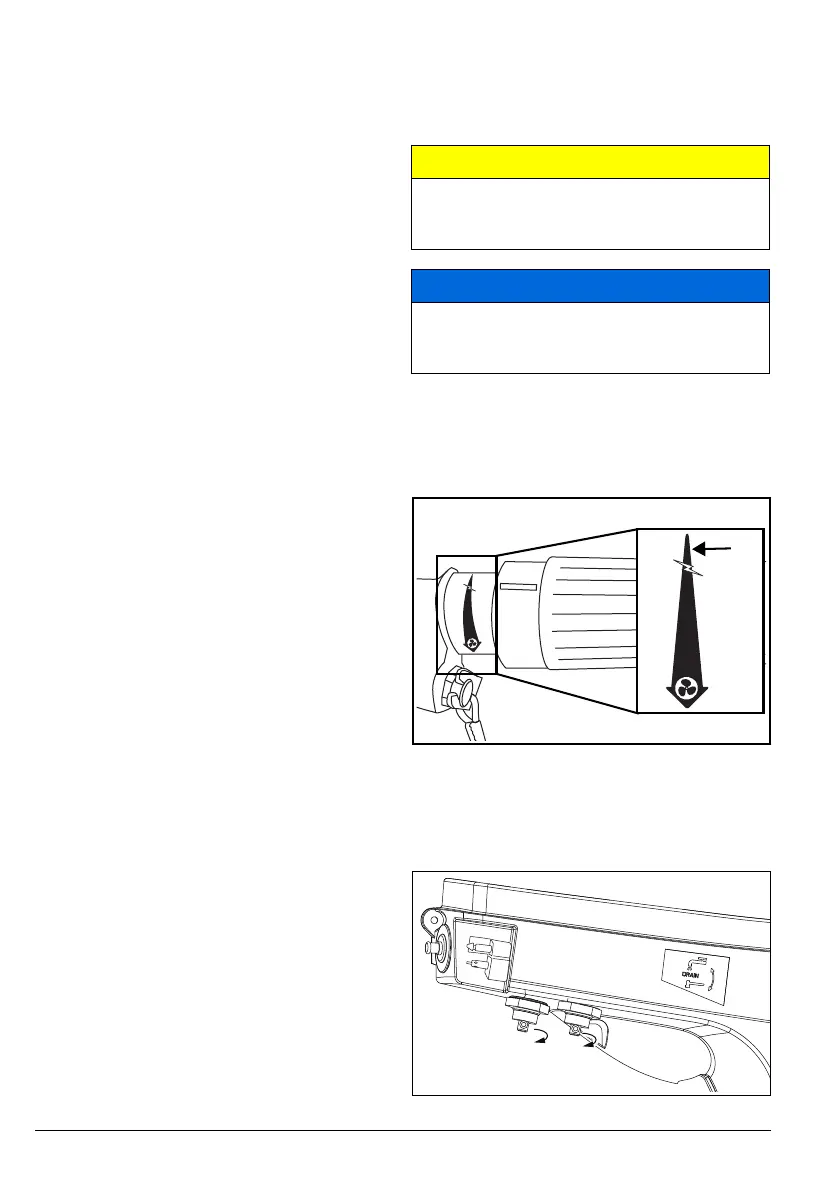

2) Twist throttle grip to slowest speed posi-

tion.

1. Slowest speed position

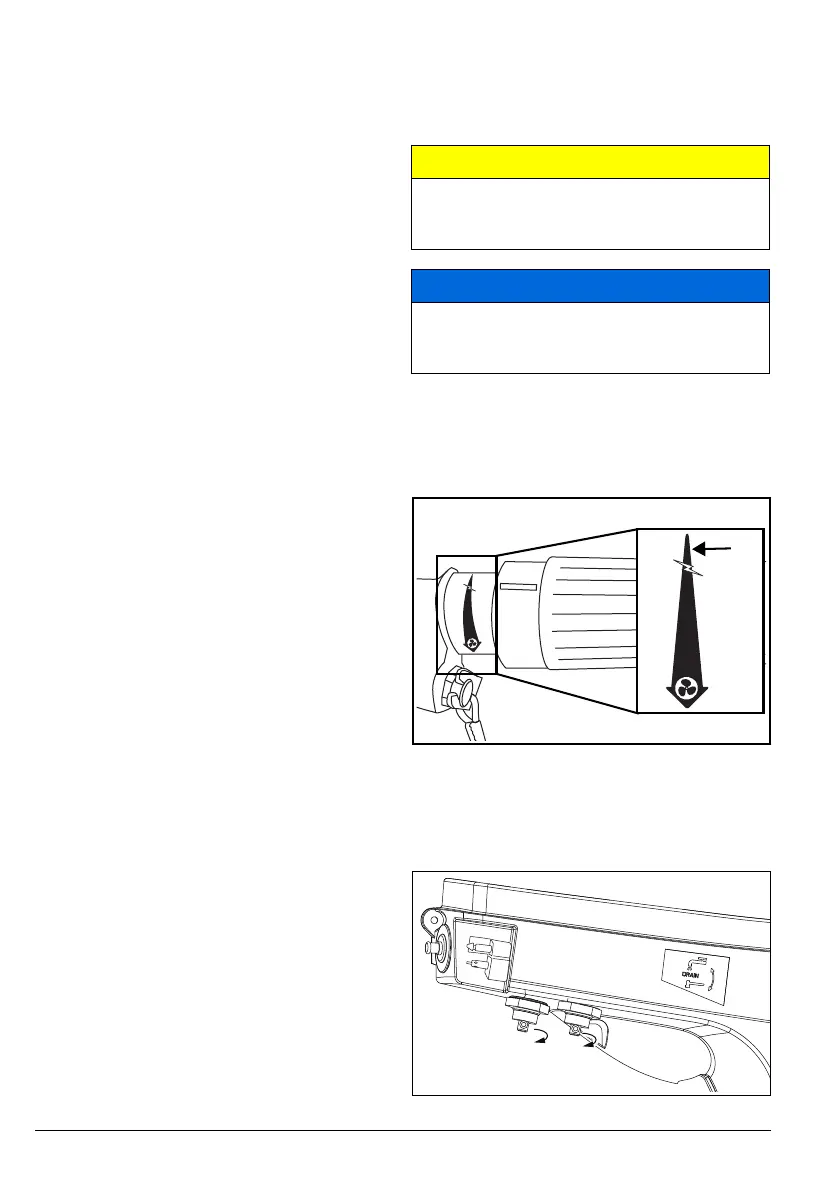

2) Turn the drain valves one–quarter turn

counter–clockwise to the DRAIN position.

Note: The handles on the drain valves will

point towards PORT.

Drain Position

To avoid outboard falling during de-

water procedure, tilt/run lever MUST

remain in the TILT position.

DO NOT run the outboard with

the drain

valves in the DRAIN position more than 3

minutes. Engine damage can result.

007067

008900

Loading...

Loading...