15

www.evolutionpowertools.com

EN

CUTTING ADVICE

Mark out all the cutting lines on the workpiece using suitable

media – pencil, crayon, chalk etc. All cutting lines should be

clear and readily visible.

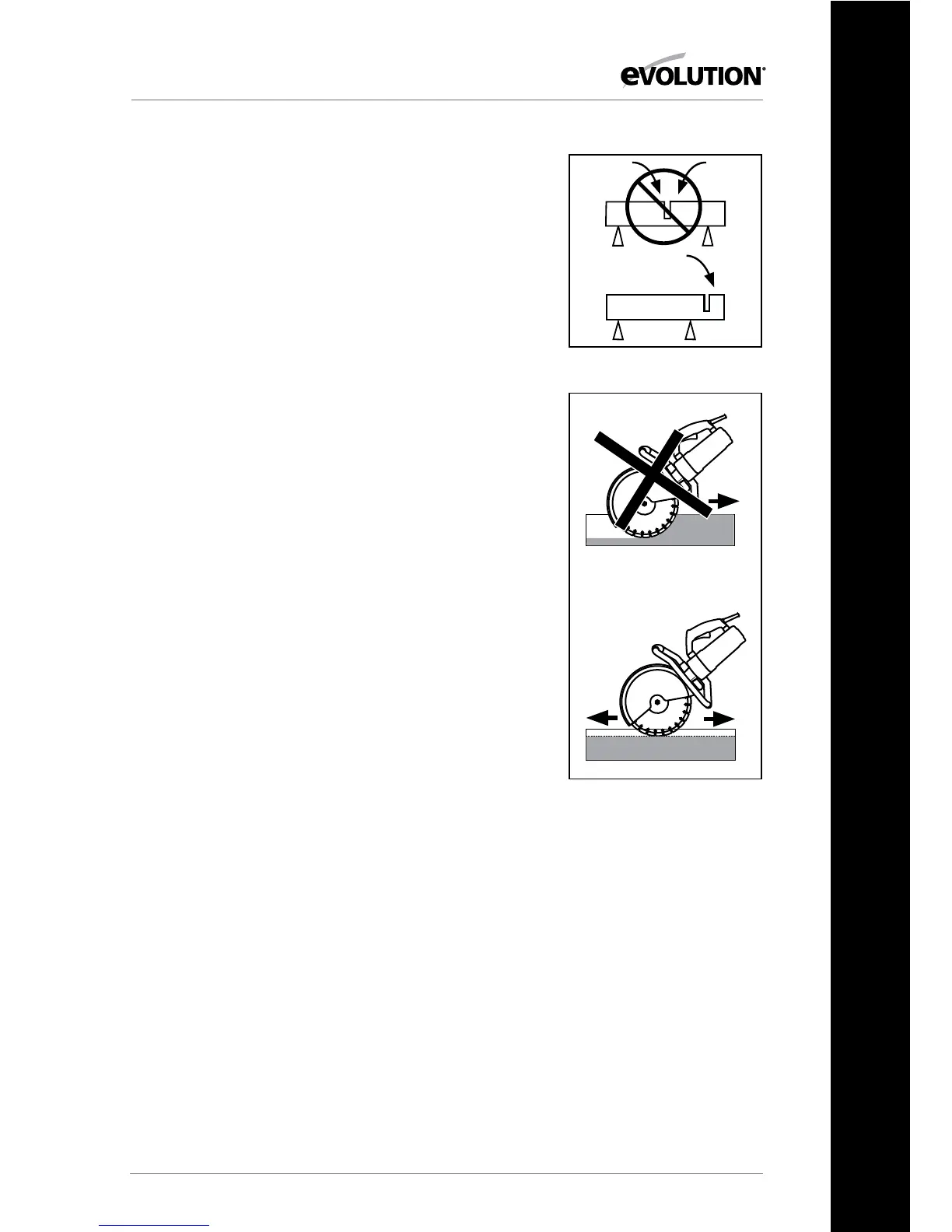

• Ifpossiblesupporttheworkpieceinsuchawaythatitis

possible to predict what will happen, and that the cut will

remain stable and open while cutting. (FIG. 7)

• Alwaysalignthediamondwheelwithapre-markedcutting

line before beginning operations, but ensure that the

diamond wheel is not touching the workpiece.

• Switchthemachine‘ON’andallowthebladetoreachitsfull

operational speed.

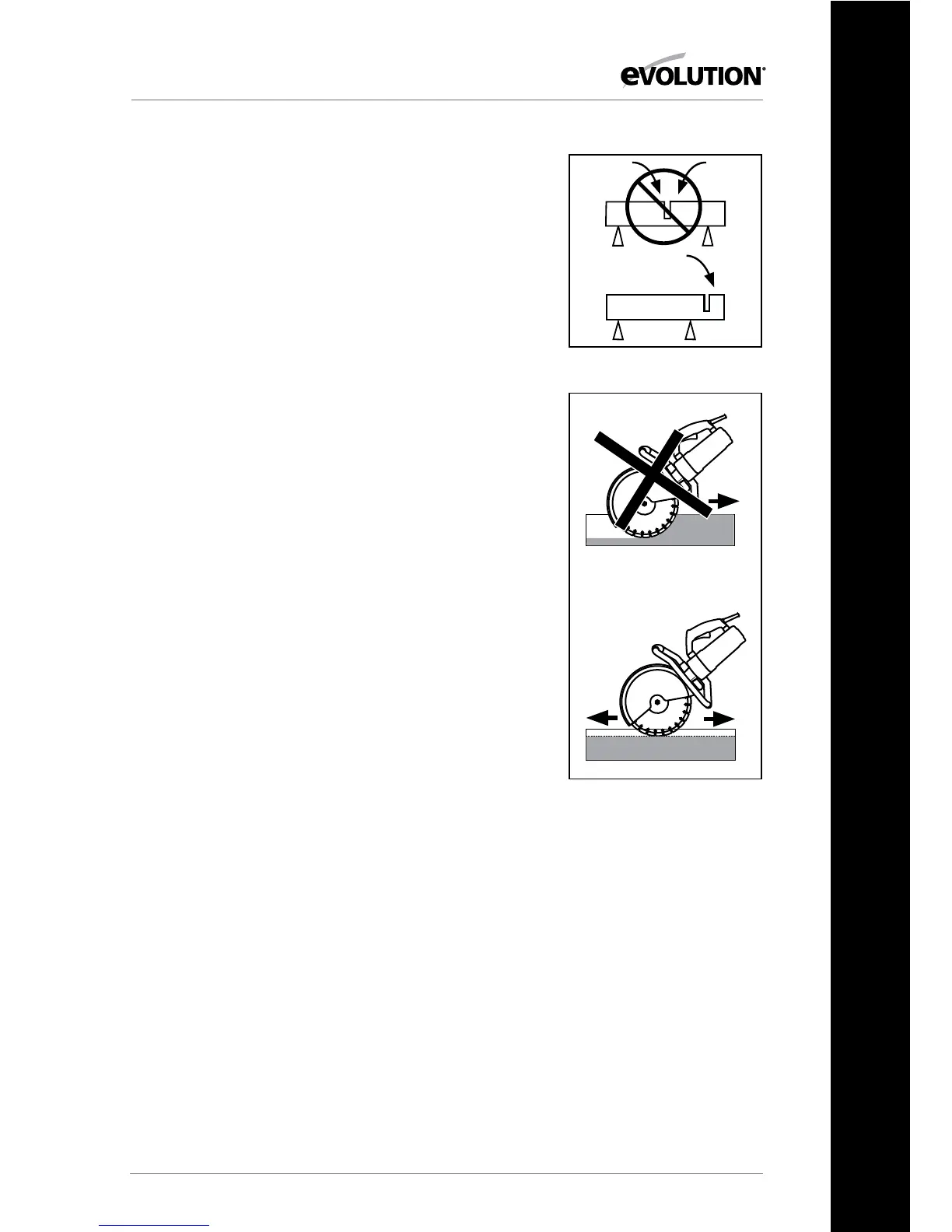

• Gentlyfeedthebladeintotheworkpiece.Cutting

performance is best when you cut straight ahead along the

pre-marked cutting line. Do not cut a depth of greater than

50mm (2”). FIG. 8 If a cut of greater than 50 mm (2”) is

required make several passes.

• Cutsmoothly,allowingthemachinetoworkwithoutforcing

the blade.

£ WARNING: Do not attempt to cut curved or zig zag lines.

Never use the side of the blade as a cutting surface. Never use

to perform inclination cutting.

• Donotapplywaterorcoolanttothediamondblade.

• Movethebladeslowlybackwardsandforwardsandtryto

achieve a small contact area between the blade and the

workpiece being cut. This reduces the temperature of the

blade and ensures efficient cutting.

• Ifthebladeseizesorthereisanyabnormalnoise,

immediately turn the power ‘OFF’ and investigate the

cause. Determine the cause of any noise or stoppage. Only

recommence cutting if it is safe to do so.

• Feedthemachinedowninlinewiththeblade.Sideways

pressure on the blade disc can damage it and can be very

dangerous.

FIG. 7

FIG. 8

Loading...

Loading...