IONPURE

®

LX CEDI Modules

Page 13 IP-MAN-LX-1220-EN.pdf

within these specifications. Depending on the conditions, however, some sites may

require additional pretreatment. To determine if additional pretreatment is required,

compare the LX feed water on site with the feed water requirements listed below.

NOTE: Recycling the LX reject to the RO feed will cause the CO

2

load on the LX to

increase, and may have an impact on the LX product water quality. Please refer to

Ionpure.com for additional reject stream system design guidance including the following

paper: “Process and System Design for Reliable Operation of RO/CEDI Systems”,

Jonathan Wood and Joe Gifford, International Water Conference, 2004 (Paper 47).

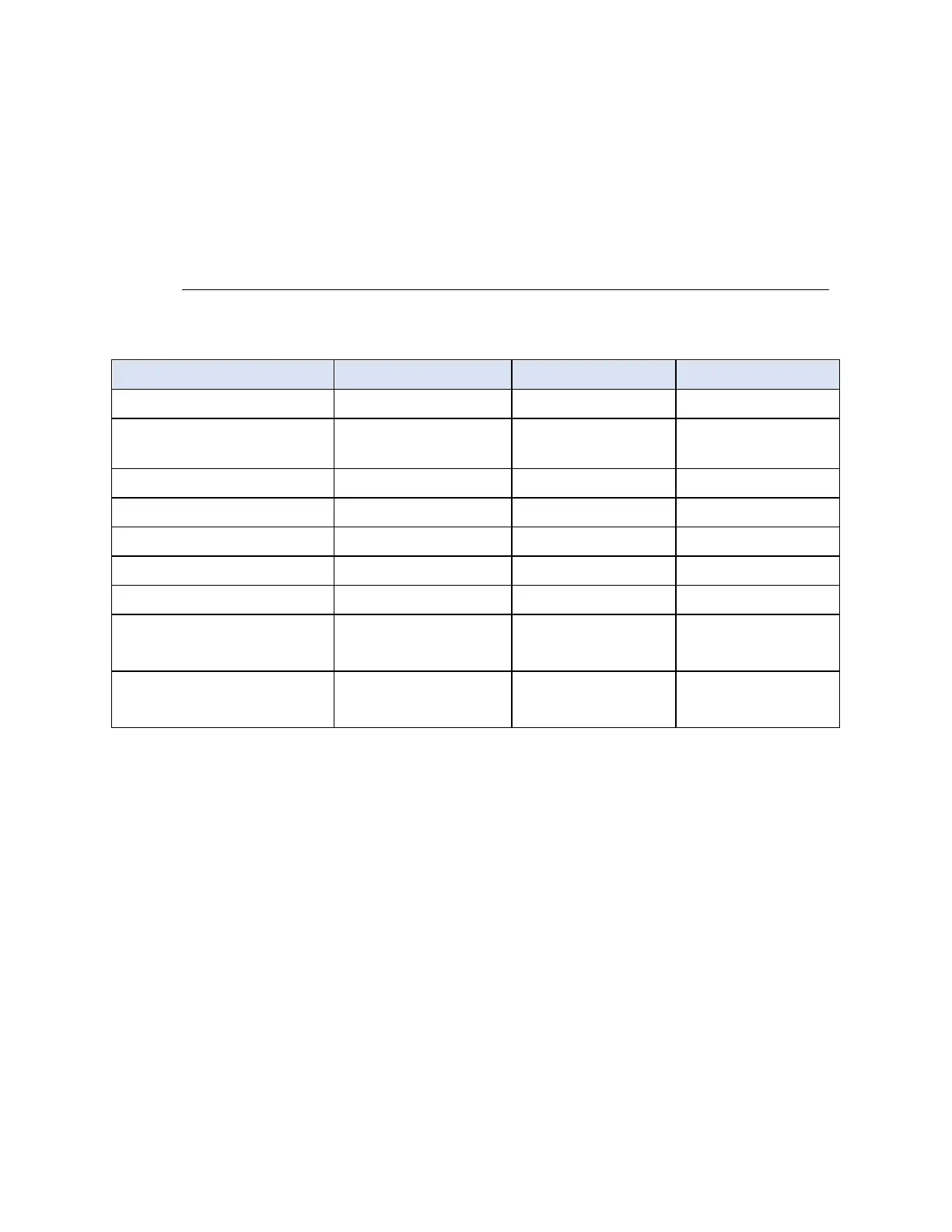

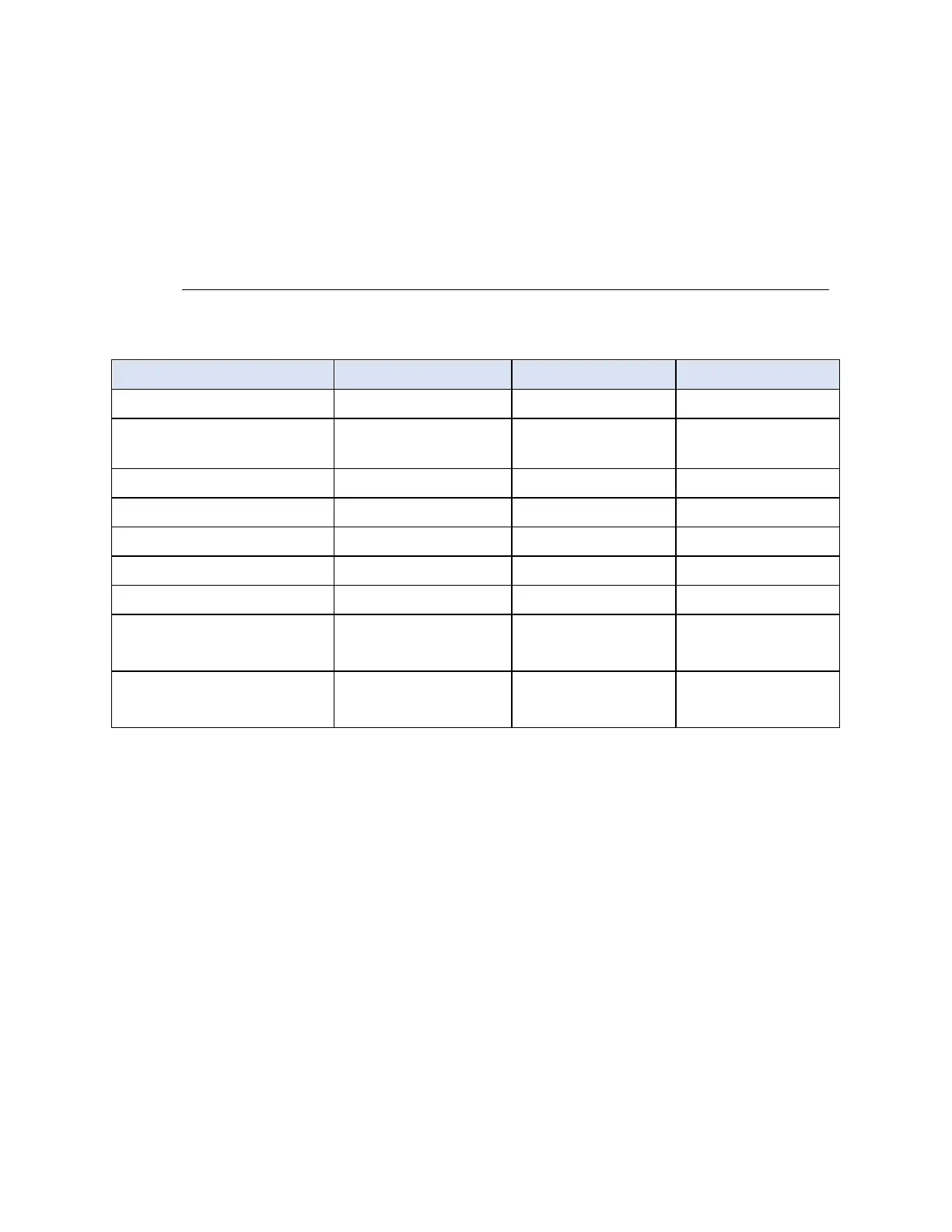

Table 2-3. CEDI Feed Water (RO Permeate) Requirements - Also See Appendix A.2

Parameter EU, X Z HI

FCE* (µS/cm) ≤ 40 µS/cm ≤ 40 µS/cm ≤ 40 µS/cm

Total hardness (as

CaCO

3

)

≤ 1.0 ppm ≤ 1.0 ppm ≤ 1.0 ppm

Total chlorine (as Cl

2

) ≤ 0.02 ppm ≤ 0.05 ppm ≤ 0.02 ppm

Silica (ppm as SiO

2

) ≤ 1.0 ppm ≤ 1.0 ppm ≤ 1.0 ppm

Iron, manganese, sulfide ≤ 0.01 ppm ≤ 0.01 ppm ≤ 0.01 ppm

TOC (ppm as C) ≤ 0.5 ppm ≤ 0.5 ppm ≤ 0.5 ppm

Operating pH range 4 – 11 4 – 11 4 – 11

Feed water temperature

41 - 113 °F

(5 – 45 °C)

41 - 113 °F

(5 – 45 °C)

41 - 140 °F

(5 – 60 °C)

Inlet pressure

≤ 100 psig

(6.9 bar)

≤ 100 psig

(6.9 bar)

≤ 100 psig

(6.9 bar)

*FCE stands for feed (water) conductivity equivalent)

FCE = measured µS/cm + (ppm CO

2

)(2.79) + (ppm SiO

2

)(2.04)

2.4.6. Drain Requirements

Place the LX module near a drain that can accommodate 100% of the total feed flow.

2.5. Flow Rates and Pressure Drops

See Appendix A, Table A.2.

Loading...

Loading...