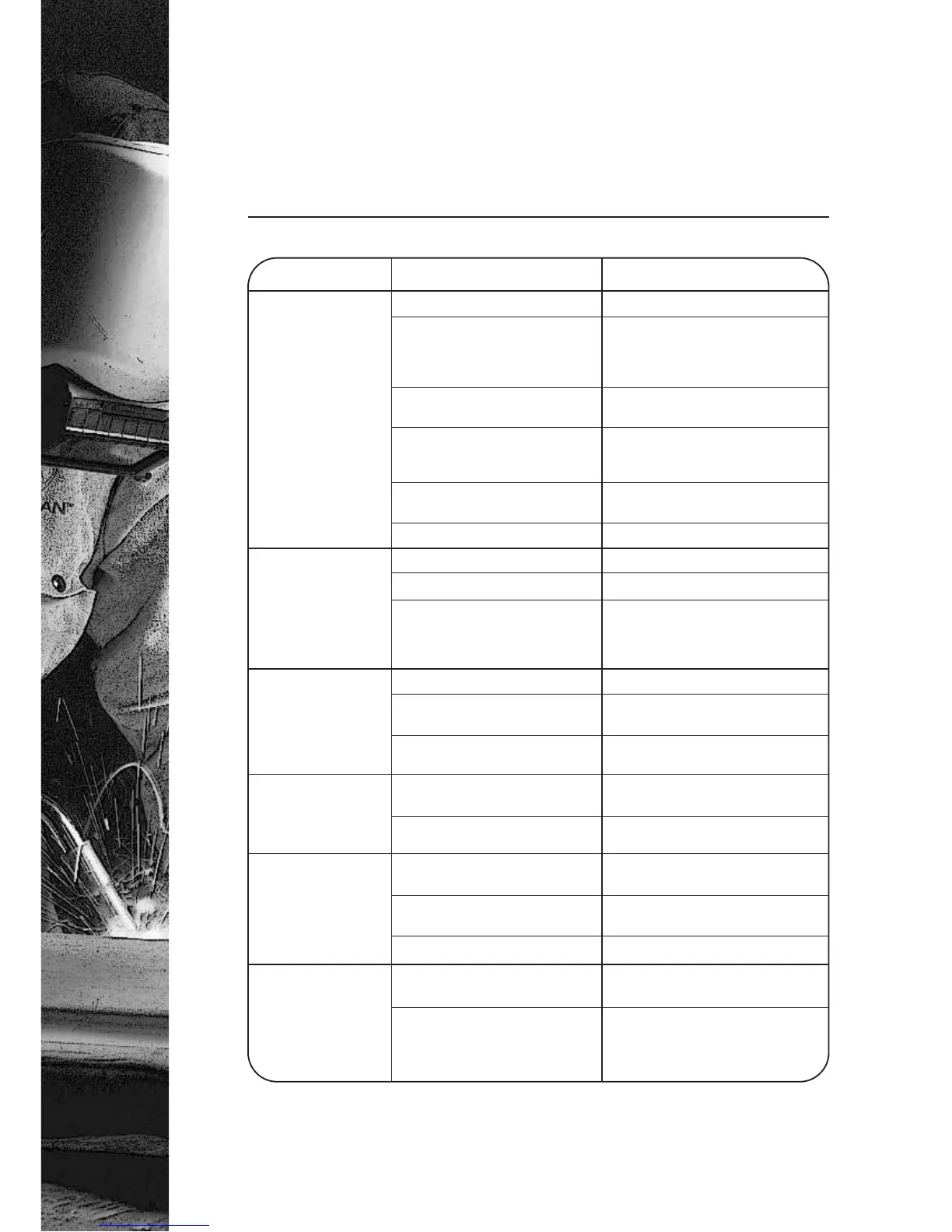

18 Troubleshooting Guide

Spiral is dirty. Clean the spiral.

Channels of the drive reels are

not compatible with wire type or

diameter being used.

Check the channels of reels and

change with the reels suitable for

the used wire. Clean the grooves.

Channels of drive reels are worn

or grooves are crushed.

Replace worn reels with the new

ones.

Welding wire jammed in contact

nozzle.

Remove the welding wire from

contact nozzle Replece the contact.

nozzle if necessary.

Wire feed engine is faulty. Contact with technical service.

Control board (PC-board) is faulty.

Contact with technical service.

Control cable (multiple cable) is

faulty.

Change the control cable.

Trigger of welding torch is faulty.

Replace the trigger of welding torch.

Problem in energy inlet.

Check the power unit and mains

supply connection. Turn on the

machine if it is closed. If inlet fuse

blown, change the fuse.

REASON SOLUTIONPROBLEM

Control board (PC-board) is faulty. Contact with technical service.

Control cable (multiple cable) is

faulty.

Change the control cable.

Current setting potentiometer is

faulty.

Change the potentiometer.

There is no energy in AC Contact with technical service.

Control board (PC-board) is faulty. Contact with technical service.

There is wire feeding

and gas flow, but

there is no open

circuit voltage.

Supply voltage value is too low

(under 350 V).

Check the supply voltage as to be

380 10%V.±

One of the phases is missing in

supply voltage.

Check the mains phases.

Open circuit voltage

is low.

Diode gropu is faulty.

Change the diode group.

There is disconnection in

grounding cable.

Check the grounding cable

connection.

There is too much oil, dirt and

rust on workpiece. The contact

between work clamp and

workpiece is not good.

Provide good contact between the

surfaces by performing necessary

cleaning.

There is open circuit

voltage and wire

feeding function

operates. But there

is no arc.

Expressweld MasterMIG 500W

Page 32

There is problem

in wire feeder

unit, engine

operates but wire

does not

advance

properly.

Grooves are dirty.

There is problem in

wire feeder unit,

engine doesn t

operate. When

pressed on torch

trigger, wire doesn t

advance.

'

'

There is open circuit

voltage and gas

flow, but wire

feeding functions

doesn t operate.'

contactor coil.

Loading...

Loading...